- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

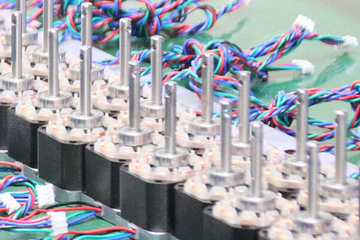

Changzhou LeanMotor Co., Ltd is a professional stepper motor & brushless dc motor manufacturer with 15years manufacturing experience, Our company specialises in the production of all kinds of hybrid stepper motors, linear motions, dc brushless motors, integrated servo motors and related drives, with an annual output of more than 2 million units, in addition, we have several cooperative factories specialising in the production of all kinds of permanent magnet stepping motors, brushed DC motors, 2 phase and 3 phase AC motors, gearboxes, encoders, brakes, etc. Our products are exported to more than 30 countries and regions, such as the United States, Germany, Switzerland, Italy, France and so on.

LeanMotor's stepper motors cover 2phase or 3phase hybrid stepper motors, motor size including nema 8 11 14 16 17 23 24 34 42 52 step motors, and we also have many excellent suppliers providing gearbox, brake, encoder or other motor related parts.

Our all products passed CE Rohs, Reach, ISO 9001 and ISO14001 certificated. We can professionally customize and provide customized services for all the needs of our customers for the use of stepper motors.

A diverse range of products and bespoke services to match the optimal solution for your project.

Providing high quality OEM ODM customized service, motor customized including wires, shafts, motor parameters, covers and so on. Related parts cover

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

Title: Classification of Stepper MotorsStepper motors are widely used in various industries for their precise control and positioning capabilities. Among the different types of stepper motors available, the LeanMotor brand offers a range of options suitable for diverse applications. In this article,

Title: The Working Principle of Stepper Motors by LeanMotorStepper motors are a fascinating and essential component in various industries, providing precise control over rotational motion. Among the leading brands in this field, LeanMotor stands out as a reliable and innovative provider of stepper m

What is a Stepper Motor?A stepper motor is a type of electromechanical device that converts electrical pulses into precise mechanical movement. Unlike conventional motors that rotate continuously when powered, a stepper motor moves in discrete steps, meaning it rotates in fixed angles (called steps)