- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 0.4 A-1.7A

Customized: Connectors, Gearbox, Encoder, Brake, Lead Screw, Integrated Driver...

| Availability: | |

|---|---|

| Quantity: | |

Nema 17 Common Planetary Geared Stepper Motor

LeanMotor

4 poles

Gearbox Motors

Nema17 (42mm)

4wires, 6wires

2 Phase

0.9°, 1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° or 0.9° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HM34-1334 | 0.9 | 34 | 1.33 | 2.1 | 4.2 | 2.2 | 4 | 200 | 35 | 0.22 |

| LM42HM40-1684 | 0.9 | 40 | 1.68 | 1.65 | 3.2 | 3.3 | 4 | 220 | 54 | 0.28 |

| LM42HM48-1684 | 0.9 | 48 | 1.68 | 1.65 | 4.1 | 4.4 | 4 | 250 | 68 | 0.38 |

| LM42HM60-1684 | 0.9 | 60 | 1.68 | 1.65 | 5 | 5.5 | 4 | 270 | 106 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HS25-0404 | 1.8 | 25 | 0.4 | 24 | 36 | 1.5 | 4 | 75 | 20 | 0.15 |

| LM42HS28-0504 | 1.8 | 28 | 0.5 | 20 | 21 | 1.8 | 4 | 85 | 24 | 0.22 |

| LM42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 120 | 34 | 0.22 |

| LM42HS34-0956 | 1.8 | 34 | 0.95 | 4.2 | 2.5 | 2.2 | 6 | 120 | 34 | 0.22 |

| LM42HS40-1704 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 150 | 54 | 0.28 |

| LM42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 3.2 | 6 | 150 | 54 | 0.28 |

| LM42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 5.5 | 4 | 260 | 68 | 0.38 |

| LM42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 4 | 6 | 260 | 68 | 0.38 |

| LM42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.55 |

| LM42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

| Item | Specifications |

| Step Angle | 1.8° or 0.9° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HM34-1334 | 0.9 | 34 | 1.33 | 2.1 | 4.2 | 2.2 | 4 | 200 | 35 | 0.22 |

| LM42HM40-1684 | 0.9 | 40 | 1.68 | 1.65 | 3.2 | 3.3 | 4 | 220 | 54 | 0.28 |

| LM42HM48-1684 | 0.9 | 48 | 1.68 | 1.65 | 4.1 | 4.4 | 4 | 250 | 68 | 0.38 |

| LM42HM60-1684 | 0.9 | 60 | 1.68 | 1.65 | 5 | 5.5 | 4 | 270 | 106 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HS25-0404 | 1.8 | 25 | 0.4 | 24 | 36 | 1.5 | 4 | 75 | 20 | 0.15 |

| LM42HS28-0504 | 1.8 | 28 | 0.5 | 20 | 21 | 1.8 | 4 | 85 | 24 | 0.22 |

| LM42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 120 | 34 | 0.22 |

| LM42HS34-0956 | 1.8 | 34 | 0.95 | 4.2 | 2.5 | 2.2 | 6 | 120 | 34 | 0.22 |

| LM42HS40-1704 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 150 | 54 | 0.28 |

| LM42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 3.2 | 6 | 150 | 54 | 0.28 |

| LM42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 5.5 | 4 | 260 | 68 | 0.38 |

| LM42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 4 | 6 | 260 | 68 | 0.38 |

| LM42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.55 |

| LM42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

| Model | / | LM-FLE42-L1 | LM-FLE42-L2 | |||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 50 | 100 |

| Gear Trains | / | 1 | 2 | |||||

| Gearbox Length | mm | 61.5 | 72.5 | |||||

| Rated Torque | N.m | 9 | 9 | 5 | 10 | 10 | 10 | 5 |

| Sundden Stop Torque | N.m | 18 | 18 | 10 | 20 | 20 | 20 | 10 |

| Back Lash | arcmin | ≤30 arcmin | ≤45arcmin | |||||

| Efficiency | % | 90 | 80 | |||||

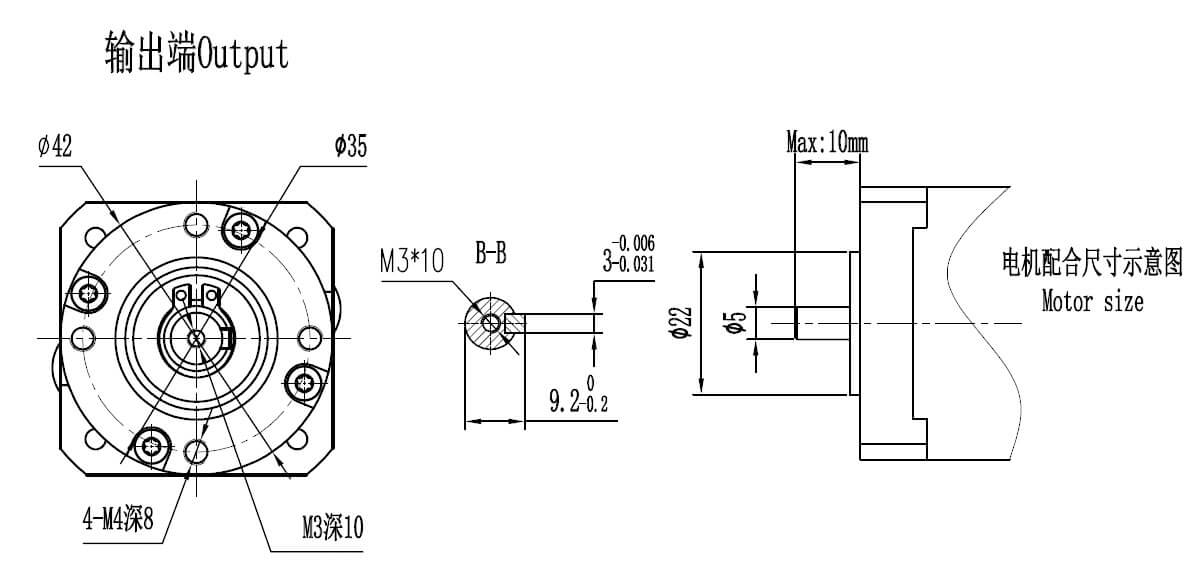

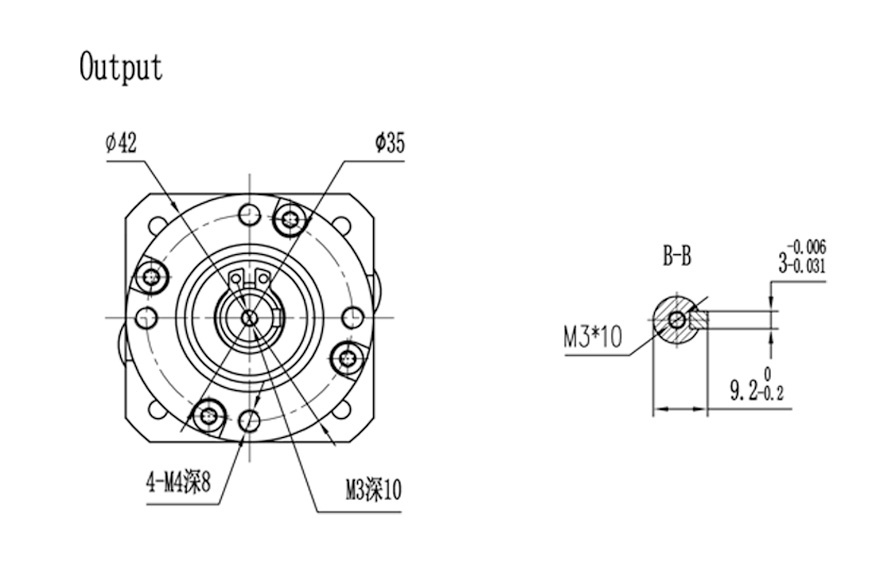

| Suitable Motor Dimension | mm | Φ5-10 / Φ22-2 / F31-M3 | Φ5-10 / Φ22-2 / F31-M3 | |||||

| Rated Input Speed | Rpm | 1000 | 1000 | |||||

| Max Input Speed | Rpm | 2000 | 2000 | |||||

| Average Life Span | h | 20000 | 20000 | |||||

| Axial Force | N | 100 | 100 | |||||

| Radial Force | N | 300 | 300 | |||||

| Noise | dB | ≤55 | ≤55 | |||||

| Protection Level | IP | IP54 | IP54 | |||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||

| Model | / | JK-FLE42-L1SW | JK-FLE42-L2SW | |||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 50 | 100 |

| Gear Trains | / | 1 | 2 | |||||

| Gearbox Length | mm | 76.5 | 87.5 | |||||

| Rated Torque | N.m | 9 | 9 | 5 | 10 | 10 | 10 | 10 |

| Sundden Stop Torque | N.m | 18 | 18 | 10 | 20 | 20 | 20 | 20 |

| Back Lash | arcmin | ≤30 arcmin | ≤45 arcmin | |||||

| Efficiency | % | 90 | 80 | |||||

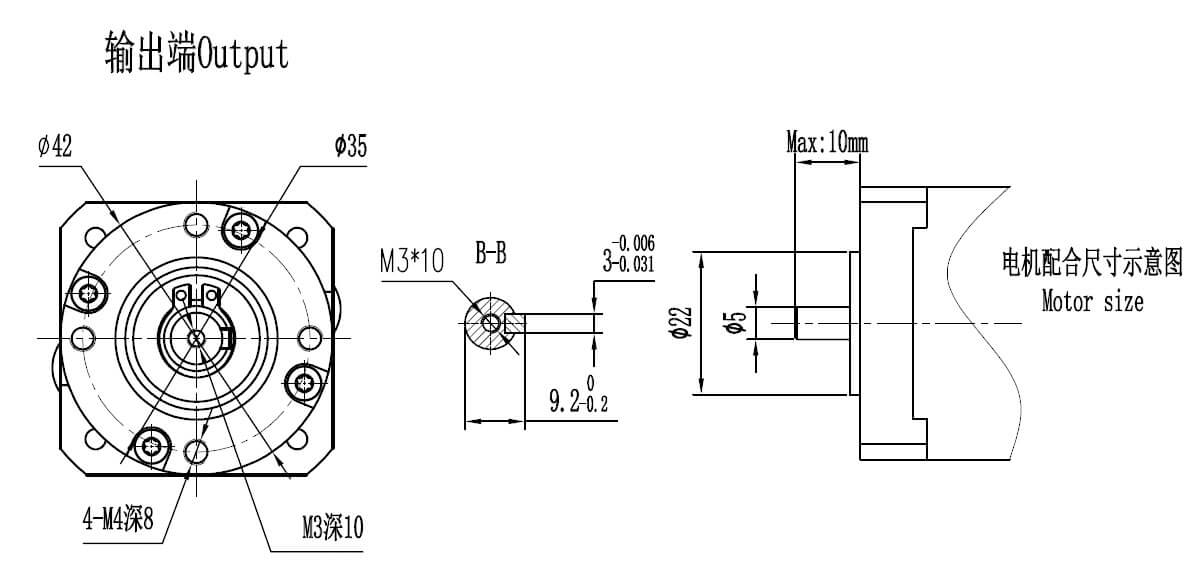

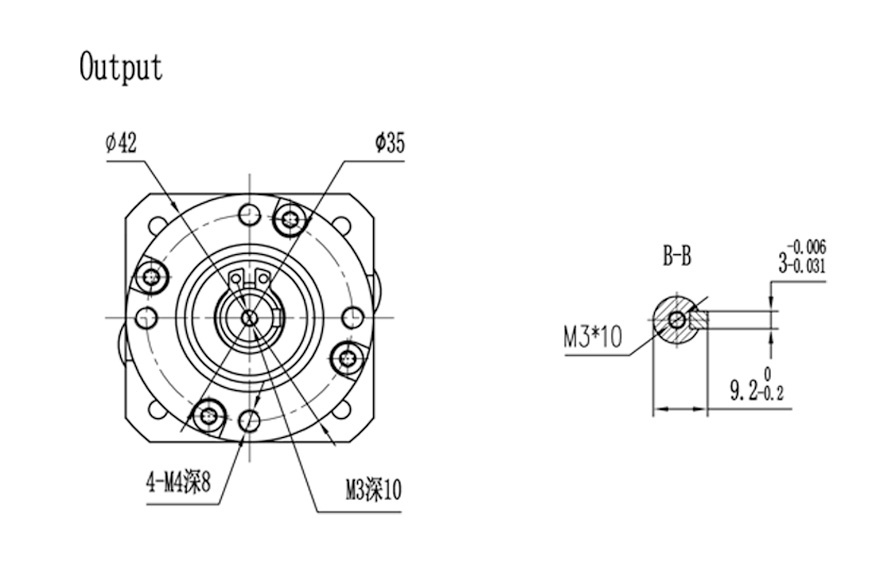

| Suitable Motor Dimension | mm | Φ5-24 / Φ22-2 / F31-M3 | Φ5-24 / Φ22-2 / F31-M3 | |||||

| Rated Input Speed | Rpm | 1000 | 1000 | |||||

| Max Input Speed | Rpm | 2000 | 2000 | |||||

| Average Life Span | h | 20000 | 20000 | |||||

| Axial Force | N | 100 | 100 | |||||

| Radial Force | N | 300 | 300 | |||||

| Noise | dB | ≤55 | ≤55 | |||||

| Protection Level | IP | IP54 | IP54 | |||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||

| Model | / | LM-FLE42-L1 | LM-FLE42-L2 | |||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 50 | 100 |

| Gear Trains | / | 1 | 2 | |||||

| Gearbox Length | mm | 61.5 | 72.5 | |||||

| Rated Torque | N.m | 9 | 9 | 5 | 10 | 10 | 10 | 5 |

| Sundden Stop Torque | N.m | 18 | 18 | 10 | 20 | 20 | 20 | 10 |

| Back Lash | arcmin | ≤30 arcmin | ≤45arcmin | |||||

| Efficiency | % | 90 | 80 | |||||

| Suitable Motor Dimension | mm | Φ5-10 / Φ22-2 / F31-M3 | Φ5-10 / Φ22-2 / F31-M3 | |||||

| Rated Input Speed | Rpm | 1000 | 1000 | |||||

| Max Input Speed | Rpm | 2000 | 2000 | |||||

| Average Life Span | h | 20000 | 20000 | |||||

| Axial Force | N | 100 | 100 | |||||

| Radial Force | N | 300 | 300 | |||||

| Noise | dB | ≤55 | ≤55 | |||||

| Protection Level | IP | IP54 | IP54 | |||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||

| Model | / | JK-FLE42-L1SW | JK-FLE42-L2SW | |||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 50 | 100 |

| Gear Trains | / | 1 | 2 | |||||

| Gearbox Length | mm | 76.5 | 87.5 | |||||

| Rated Torque | N.m | 9 | 9 | 5 | 10 | 10 | 10 | 10 |

| Sundden Stop Torque | N.m | 18 | 18 | 10 | 20 | 20 | 20 | 20 |

| Back Lash | arcmin | ≤30 arcmin | ≤45 arcmin | |||||

| Efficiency | % | 90 | 80 | |||||

| Suitable Motor Dimension | mm | Φ5-24 / Φ22-2 / F31-M3 | Φ5-24 / Φ22-2 / F31-M3 | |||||

| Rated Input Speed | Rpm | 1000 | 1000 | |||||

| Max Input Speed | Rpm | 2000 | 2000 | |||||

| Average Life Span | h | 20000 | 20000 | |||||

| Axial Force | N | 100 | 100 | |||||

| Radial Force | N | 300 | 300 | |||||

| Noise | dB | ≤55 | ≤55 | |||||

| Protection Level | IP | IP54 | IP54 | |||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

It is a NEMA 17 size stepper motor combined with a planetary gearbox, designed to deliver higher torque, better load handling, and improved positioning accuracy compared to a standard stepper motor.

Planetary gearboxes provide higher torque density, better efficiency, lower backlash, and longer service life due to load sharing among multiple gears.

The gearbox multiplies the motor’s output torque according to the gear ratio, making it suitable for applications requiring high torque at low speeds.

Typical gear ratios include 5:1, 10:1, 20:1, 30:1, 50:1, and higher, depending on torque and speed requirements.

The gearbox increases effective step resolution, allowing for finer positioning and smoother motion, which is ideal for precision equipment.

Backlash is usually much lower than spur gear systems, often in the range of a few arc minutes depending on gearbox grade.

These motors typically support multiple voltage and current options, making them compatible with common stepper drivers and controllers.

Standard options include round shaft, D-shaft, keyed shaft, and custom shaft designs to match different coupling requirements.

Common applications include CNC machines, 3D printers, robotics, medical devices, automated valves, packaging machines, and laboratory equipment.

With hardened gears, precision machining, and proper lubrication, the motor offers long operational life and stable performance under continuous load.

Yes. Factories can customize gear ratios based on required torque, speed, and application-specific performance needs.

Yes. Coil resistance, rated voltage, and current can be adjusted to match different drivers or power systems.

Custom shaft length, diameter, and end machining (threads, flats, keyways) can be manufactured upon request.

Yes. Optical or magnetic encoders can be integrated to provide position feedback for closed-loop control systems.

Depending on application needs, gear materials such as hardened steel or metal alloys can be selected for higher strength or quieter operation.

Yes. Factories can optimize gear profiles, lubrication, and motor tuning to reduce vibration and noise.

Most manufacturers support OEM/ODM services, including custom labels, nameplates, packaging, and documentation.

Yes. Wire length, connector type, and pin configuration can be customized to simplify customer assembly.

MOQ varies by customization level but is usually flexible for OEM customers, especially for long-term projects.

Factories use incoming material inspection, precision machining, assembly testing, torque and noise testing, and final performance validation to ensure stable quality.

It is a NEMA 17 size stepper motor combined with a planetary gearbox, designed to deliver higher torque, better load handling, and improved positioning accuracy compared to a standard stepper motor.

Planetary gearboxes provide higher torque density, better efficiency, lower backlash, and longer service life due to load sharing among multiple gears.

The gearbox multiplies the motor’s output torque according to the gear ratio, making it suitable for applications requiring high torque at low speeds.

Typical gear ratios include 5:1, 10:1, 20:1, 30:1, 50:1, and higher, depending on torque and speed requirements.

The gearbox increases effective step resolution, allowing for finer positioning and smoother motion, which is ideal for precision equipment.

Backlash is usually much lower than spur gear systems, often in the range of a few arc minutes depending on gearbox grade.

These motors typically support multiple voltage and current options, making them compatible with common stepper drivers and controllers.

Standard options include round shaft, D-shaft, keyed shaft, and custom shaft designs to match different coupling requirements.

Common applications include CNC machines, 3D printers, robotics, medical devices, automated valves, packaging machines, and laboratory equipment.

With hardened gears, precision machining, and proper lubrication, the motor offers long operational life and stable performance under continuous load.

Yes. Factories can customize gear ratios based on required torque, speed, and application-specific performance needs.

Yes. Coil resistance, rated voltage, and current can be adjusted to match different drivers or power systems.

Custom shaft length, diameter, and end machining (threads, flats, keyways) can be manufactured upon request.

Yes. Optical or magnetic encoders can be integrated to provide position feedback for closed-loop control systems.

Depending on application needs, gear materials such as hardened steel or metal alloys can be selected for higher strength or quieter operation.

Yes. Factories can optimize gear profiles, lubrication, and motor tuning to reduce vibration and noise.

Most manufacturers support OEM/ODM services, including custom labels, nameplates, packaging, and documentation.

Yes. Wire length, connector type, and pin configuration can be customized to simplify customer assembly.

MOQ varies by customization level but is usually flexible for OEM customers, especially for long-term projects.

Factories use incoming material inspection, precision machining, assembly testing, torque and noise testing, and final performance validation to ensure stable quality.