- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

A BLDC motor (brushless DC motor) is a motor with high efficiency, high torque, and a long lifespan. It is widely used in home appliances, industrial equipment, and automotive components due to it's low noise factor and power saving ability achieved through high efficiency.

BLDC motors operate using an electronic controller that delivers current to the motor windings in a precise sequence based on feedback from Hall sensors or encoders. This creates a rotating magnetic field that interacts with the permanent magnets in the rotor, producing torque and rotation.

At the same time, BLDC motors are considered more energy efficient than brushed DC-motors. This means for the same input power, a BLDC motor will convert more electrical power into mechanical power than a brushed motor, mostly due to absence of friction of brushes.

The gearbox is a mechanical device attached to the motor shaft. It reduces the motor’s high RPM (revolutions per minute) and proportionally increases its torque output. The most common types of gearboxes used with BLDC motors include:

This gear reduction system allows the motor to drive heavier loads, achieve better control at lower speeds, and extend its lifespan by minimizing direct mechanical stress.

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

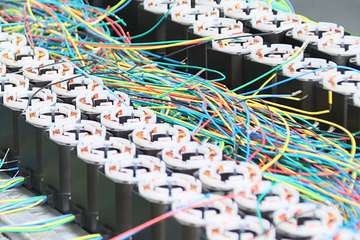

Changzhou LeanMotor Co., Ltd is a professional stepper motor & brushless dc motor manufacturer with 15years manufacturing experience, Our company specialises in the production of all kinds of hybrid stepper motors, linear motions, dc brushless motors, integrated servo motors and related drives, with an annual output of more than 2 million units, in addition, we have several cooperative factories specialising in the production of all kinds of permanent magnet stepping motors, brushed DC motors, 2 phase and 3 phase AC motors, gearboxes, encoders, brakes, etc. Our products are exported to more than 30 countries and regions, such as the United States, Germany, Switzerland, Italy, France and so on.

LeanMotor's brushless dc motors cover standard bldc motor, geared bldc motor, brake bldc motor, dc servo motor, integrated dc servo motor and so on, motor size including 33mm 42mm 57mm 60mm 80mm 86mm 110mm and 130mm, we also have many excellent suppliers providing gearbox, brake, encoder or other motor related parts.

Our all products passed CE Rohs, Reach, ISO 9001 and ISO14001 certificated. We can professionally customize and provide customized services for all the needs of our customers for the use of brushless dc motors.

Providing high quality OEM ODM customized service, motor customized including wires, shafts, motor parameters, covers and so on. Related parts cover

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

Understanding the Role of Planetary Gearboxes in Modern MachineryPlanetary gearboxes, also known as epicyclic gearboxes, are a critical component in modern mechanical systems. These compact, efficient, and high-torque gear mechanisms are extensively used across a variety of industries including auto

Introduction to Brushless MotorsA brushless motor, commonly referred to as a BLDC (Brushless DC) motor, is an advanced type of electric motor that eliminates the need for mechanical brushes and commutators used in traditional brushed DC motors. Instead, it utilizes electronic commutation through a c

Have you ever wondered how to choose the right BLDC motor for your project? Look no further! LeanMotor, a leading brand in the industry, is here to provide you with the perfect solution. With over fifteen years of experience in motor design, development, and production, LeanMotor has established its

A geared BLDC motor combines a brushless DC motor with a gearbox to reduce speed and increase torque, delivering efficient and precise motion control.

A geared BLDC motor provides higher output torque at lower speeds, making it ideal for applications that require controlled motion, load handling, and compact design.

Common options include planetary gearbox, worm gearbox, and spur gearbox, each suited to different torque, efficiency, and space requirements.

A planetary gearbox offers high torque density, high efficiency, low backlash, and compact size, making it ideal for precision-driven applications.

A worm gearbox is preferred when high reduction ratios, compact layout, or self-locking capability are required, such as in lifting or holding applications.

Spur gearbox BLDC motors are commonly used in cost-sensitive applications requiring moderate torque, simple structure, and easy maintenance.

While the BLDC motor itself is highly efficient, overall system efficiency depends on the gearbox type—planetary gearboxes are typically more efficient than worm gearboxes.

Geared BLDC motors are commonly available in 12V, 24V, 36V, and 48V, with customization for other voltage requirements.

Yes, with proper gearbox selection and thermal design, geared BLDC motors are suitable for continuous-duty applications.

Typical industries include industrial automation, robotics, medical devices, smart furniture, logistics equipment, and agricultural machinery.1. What is a brushless DC motor (BLDC motor) and how does it work?

Yes, manufacturers can configure planetary gearbox, worm gearbox, or spur gearbox combinations based on torque, speed, and space requirements.

Factories can offer a wide range of reduction ratios, from low ratios for high-speed applications to high ratios for heavy-load and low-speed systems.

Yes, output shaft types such as round, D-shaft, keyed shaft, or hollow shaft can be customized to meet mechanical integration needs.

Geared BLDC motors can be equipped with Hall sensors, optical encoders, or magnetic encoders for precise position and speed control.

Yes, optimized gear tooth design, precision machining, and high-quality bearings significantly reduce noise and vibration.

Absolutely. By selecting suitable gear materials, reinforced housings, and appropriate gear ratios, geared BLDC motors can deliver high output torque.

Yes, many factories supply geared BLDC motors with built-in drivers or matched external controllers for plug-and-play integration.

Factories can provide IP-rated geared BLDC motors (such as IP54, IP65) for outdoor or harsh industrial environments.

Quality checks include torque testing, gearbox backlash testing, noise testing, endurance testing, and electrical performance verification.

Factory customization ensures the BLDC motor, gearbox type, and reduction ratio are optimally matched, improving efficiency, lifespan, and overall system performance.