- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

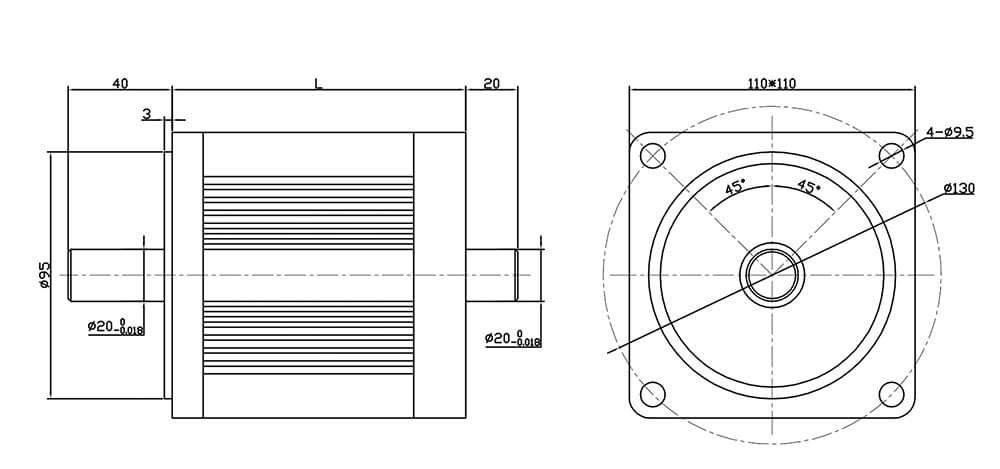

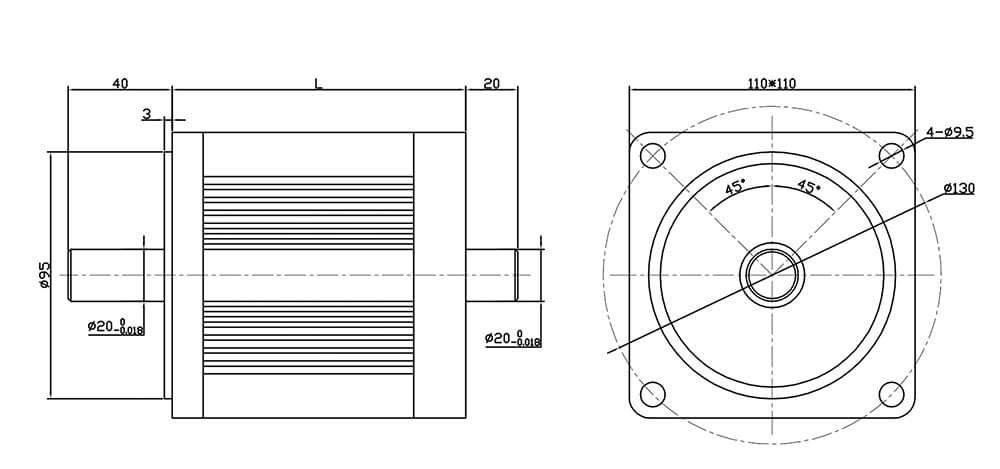

Motor Length: 83mm / 113mm / 143mm / 173mm

Rated voltage:310V

| Availability: | |

|---|---|

| Quantity: | |

Nema 42 110BLS Geared Square Head BLDC Motor with High Precision Planetary Gearbox

LeanMotor

3000 rpm

8 poles

Nema 42(110mm)

3 Phase

310V

10 Pcs

General Specifications | |

| Item | Specification |

| Winding type | Star |

| Hall effect angle | 120 degree electrical angle |

| Shaft run out | 0.025mm |

| Radial play | 0.02mm@450g |

| End play | 0.08mm@450g |

| Max.radial force | 300N@20mm from the flange |

| Max. axial force | 70N |

| Insulation class | Class B |

| Dielectric Strength | 1200VDC for one minute |

| Insulation Resistance | 100MΩ Min., 500VDC |

| Model No. | Rated voltage | Motor Length | Current | Rated power | Rotor Inertia | Rated torque | Rated speed | Weight |

| VDC | (L)mm | A | W | kg.cm² | N.m | Rpm | kg | |

| LM110BLS01 | 310 | 83 | 1.5 | 518 | 1.5 | 1.65 | 3000 | 3.3 |

| LM110BLS02 | 310 | 113 | 3.7 | 1036 | 3 | 3.3 | 3000 | 4.5 |

| LM110BLS03 | 310 | 143 | 5.6 | 1570 | 4.5 | 5 | 3000 | 5.8 |

| LM110BLS04 | 310 | 173 | 7.5 | 2073 | 6 | 6.6 | 3000 | 7 |

| Bldc Motors Wires | Hall Sensor Wires | ||||||

| U | V | W | +5VDC | GND | Hu | Hv | Hw |

| Yellow | Green | Blue | Red | Black | Yello | Green | Blue |

General Specifications | |

| Item | Specification |

| Winding type | Star |

| Hall effect angle | 120 degree electrical angle |

| Shaft run out | 0.025mm |

| Radial play | 0.02mm@450g |

| End play | 0.08mm@450g |

| Max.radial force | 300N@20mm from the flange |

| Max. axial force | 70N |

| Insulation class | Class B |

| Dielectric Strength | 1200VDC for one minute |

| Insulation Resistance | 100MΩ Min., 500VDC |

| Model No. | Rated voltage | Motor Length | Current | Rated power | Rotor Inertia | Rated torque | Rated speed | Weight |

| VDC | (L)mm | A | W | kg.cm² | N.m | Rpm | kg | |

| LM110BLS01 | 310 | 83 | 1.5 | 518 | 1.5 | 1.65 | 3000 | 3.3 |

| LM110BLS02 | 310 | 113 | 3.7 | 1036 | 3 | 3.3 | 3000 | 4.5 |

| LM110BLS03 | 310 | 143 | 5.6 | 1570 | 4.5 | 5 | 3000 | 5.8 |

| LM110BLS04 | 310 | 173 | 7.5 | 2073 | 6 | 6.6 | 3000 | 7 |

| Bldc Motors Wires | Hall Sensor Wires | ||||||

| U | V | W | +5VDC | GND | Hu | Hv | Hw |

| Yellow | Green | Blue | Red | Black | Yello | Green | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

1. What is a NEMA 42 110BLS geared brushless DC motor?

The 110BLS motor is a high-torque brushless DC (BLDC) motor with a 4.2-inch (110 mm) frame size and integrated gearbox for high precision and increased torque.

2. What are the main advantages of a geared BLDC motor?

Geared BLDC motors provide higher torque at low speeds, improved positioning accuracy, smoother operation, and longer lifespan.

3. What types of gearboxes are available for the 110BLS motor?

Available gearboxes include planetary, spur, and worm gearboxes to match torque and speed requirements.

4. How does a planetary gearbox compare to spur or worm gearboxes?

Planetary gearboxes offer high efficiency and compact design, spur gearboxes are simple and cost-effective, and worm gearboxes provide high torque with self-locking capability.

5. What voltage and current options are available?

Common voltages include 24V, 48V, and custom options depending on application requirements.

6. What torque can the NEMA 42 110BLS motor deliver?

Torque depends on motor winding, gearbox type, and reduction ratio, suitable for medium- to high-load industrial applications.

7. Can the motor operate continuously?

Yes, the motor is designed for continuous industrial operation with proper driver control and thermal management.

8. What is the typical speed range?

Speed depends on the gearbox ratio and driver, providing precision at low speeds or higher-speed operation at lower torque.

9. What industries commonly use this motor?

Applications include CNC machinery, robotics, conveyor systems, packaging equipment, medical devices, and automation systems.

10. Can this motor replace a servo motor in some applications?

Yes, in medium- to high-torque, low- to medium-speed applications, it provides a cost-effective alternative to servo motors.

11. Can the NEMA 42 110BLS motor be customized?

Yes, torque, speed, voltage, motor length, and gearbox type can be tailored for specific applications.

12. Are different gearbox ratios available?

Yes, a wide range of reduction ratios can be selected for planetary, spur, or worm gearboxes.

13. Can encoders or sensors be integrated?

Yes, Hall sensors or optical encoders can be added for closed-loop control of speed and position.

14. Can the motor be supplied with a matched BLDC driver?

Yes, compatible drivers can be provided for seamless plug-and-play operation.

15. Are low-noise or low-vibration versions available?

Yes, optimized windings, precision bearings, and high-quality gears reduce vibration and noise.

16. Can the motor be customized for harsh environments?

Yes, IP-rated housings and protective coatings can be applied for dust, moisture, or corrosive conditions.

17. What shaft types are available?

Options include solid shafts, hollow shafts, keyed shafts, or custom-machined shafts.

18. What quality control tests are performed?

Testing includes torque verification, speed and efficiency testing, vibration analysis, thermal testing, and long-term endurance testing.

19. What is the typical lead time for custom 110BLS motors?

Prototype samples typically take 2–4 weeks, while mass production usually requires 4–8 weeks.

20. How does factory-level customization improve performance?

Customization ensures optimal matching of motor, gearbox, and load, improving efficiency, precision, reliability, and service life.

1. What is a NEMA 42 110BLS geared brushless DC motor?

The 110BLS motor is a high-torque brushless DC (BLDC) motor with a 4.2-inch (110 mm) frame size and integrated gearbox for high precision and increased torque.

2. What are the main advantages of a geared BLDC motor?

Geared BLDC motors provide higher torque at low speeds, improved positioning accuracy, smoother operation, and longer lifespan.

3. What types of gearboxes are available for the 110BLS motor?

Available gearboxes include planetary, spur, and worm gearboxes to match torque and speed requirements.

4. How does a planetary gearbox compare to spur or worm gearboxes?

Planetary gearboxes offer high efficiency and compact design, spur gearboxes are simple and cost-effective, and worm gearboxes provide high torque with self-locking capability.

5. What voltage and current options are available?

Common voltages include 24V, 48V, and custom options depending on application requirements.

6. What torque can the NEMA 42 110BLS motor deliver?

Torque depends on motor winding, gearbox type, and reduction ratio, suitable for medium- to high-load industrial applications.

7. Can the motor operate continuously?

Yes, the motor is designed for continuous industrial operation with proper driver control and thermal management.

8. What is the typical speed range?

Speed depends on the gearbox ratio and driver, providing precision at low speeds or higher-speed operation at lower torque.

9. What industries commonly use this motor?

Applications include CNC machinery, robotics, conveyor systems, packaging equipment, medical devices, and automation systems.

10. Can this motor replace a servo motor in some applications?

Yes, in medium- to high-torque, low- to medium-speed applications, it provides a cost-effective alternative to servo motors.

11. Can the NEMA 42 110BLS motor be customized?

Yes, torque, speed, voltage, motor length, and gearbox type can be tailored for specific applications.

12. Are different gearbox ratios available?

Yes, a wide range of reduction ratios can be selected for planetary, spur, or worm gearboxes.

13. Can encoders or sensors be integrated?

Yes, Hall sensors or optical encoders can be added for closed-loop control of speed and position.

14. Can the motor be supplied with a matched BLDC driver?

Yes, compatible drivers can be provided for seamless plug-and-play operation.

15. Are low-noise or low-vibration versions available?

Yes, optimized windings, precision bearings, and high-quality gears reduce vibration and noise.

16. Can the motor be customized for harsh environments?

Yes, IP-rated housings and protective coatings can be applied for dust, moisture, or corrosive conditions.

17. What shaft types are available?

Options include solid shafts, hollow shafts, keyed shafts, or custom-machined shafts.

18. What quality control tests are performed?

Testing includes torque verification, speed and efficiency testing, vibration analysis, thermal testing, and long-term endurance testing.

19. What is the typical lead time for custom 110BLS motors?

Prototype samples typically take 2–4 weeks, while mass production usually requires 4–8 weeks.

20. How does factory-level customization improve performance?

Customization ensures optimal matching of motor, gearbox, and load, improving efficiency, precision, reliability, and service life.