- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

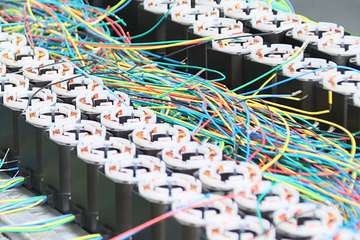

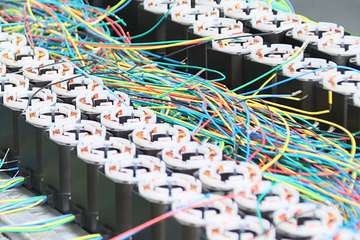

Changzhou LeanMotor Co., Ltd is a professional stepper motor & brushless dc motor manufacturer with 15years manufacturing experience, Our company specialises in the production of all kinds of hybrid stepper motors, linear motions, dc brushless motors, integrated servo motors and related drives, with an annual output of more than 2 million units, in addition, we have several cooperative factories specialising in the production of all kinds of permanent magnet stepping motors, brushed DC motors, 2 phase and 3 phase AC motors, gearboxes, encoders, brakes, etc. Our products are exported to more than 30 countries and regions, such as the United States, Germany, Switzerland, Italy, France and so on.

LeanMotor's brushless dc motors cover standard bldc motor, geared bldc motor, brake bldc motor, dc servo motor, integrated dc servo motor and so on, motor size including 33mm 42mm 57mm 60mm 80mm 86mm 110mm and 130mm, we also have many excellent suppliers providing gearbox, brake, encoder or other motor related parts.

Our all products passed CE Rohs, Reach, ISO 9001 and ISO14001 certificated. We can professionally customize and provide customized services for all the needs of our customers for the use of stepper motors.

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

Introduction to Brushless MotorsA brushless motor, commonly referred to as a BLDC (Brushless DC) motor, is an advanced type of electric motor that eliminates the need for mechanical brushes and commutators used in traditional brushed DC motors. Instead, it utilizes electronic commutation through a c

Introduction: In today's rapidly evolving technological landscape, choosing the right BLDC (Brushless DC) motor has become crucial for various industries. LeanMotor, a reputable brand in the market, offers a wide range of BLDC motors and related components. With fifteen years of experience in motor

Introduction: Welcome to another exciting blog post where we will explore the world of brushless motors. In this article, we will be focusing on the brand LeanMotor and discussing the various features and benefits of brushless motors. If you're curious about how these motors work and why they are ga

A brushless DC motor, also known as a BLDC motor, uses electronic commutation instead of brushes to control current flow, resulting in higher efficiency, longer lifespan, and lower maintenance.

BLDC motors offer higher efficiency, quieter operation, better speed control, reduced heat generation, and a significantly longer service life than brushed motors.

A brushless DC motor provides precise speed control, stable torque output, and long-term reliability, making it ideal for push rod actuators used in automation, medical, and industrial equipment.

Most brushless DC motors are available in common voltages such as 12V, 24V, 36V, and 48V, with customization options for special applications.

Yes, when combined with gearboxes or lead screw mechanisms, a BLDC motor can provide high torque and smooth low-speed operation for push rod and linear motion systems.

Brushless DC motors typically achieve efficiencies above 85–90%, making them ideal for energy-sensitive applications.

Yes, the brushless design minimizes wear and heat, allowing BLDC motors to operate continuously with high reliability.

BLDC motors can be controlled using PWM, Hall sensors, sensorless controllers, or integrated drivers depending on performance requirements.

Common industries include medical devices, smart furniture, industrial automation, robotics, automotive systems, and renewable energy equipment.

A well-designed brushless DC motor can operate for over 20,000–30,000 hours, depending on load and environmental conditions.

Yes, manufacturers can customize BLDC motors for push rod actuators, including stroke length, speed, thrust force, and mounting structure.

Customization options include voltage, power rating, speed, torque, shaft design, gear ratio, encoder integration, and housing materials.

Yes, factories can integrate brushless DC motors with planetary gearboxes, worm gears, or lead screws for compact linear actuator solutions.

Many factories offer IP-rated brushless DC motors (such as IP54, IP65, or higher) for harsh or outdoor environments.

Yes, BLDC motors can be supplied with built-in drivers, controllers, or complete motor-control modules for plug-and-play applications.

Professional motor factories typically support both OEM and ODM services, from concept design to mass production.

Factories perform torque testing, efficiency testing, noise testing, lifespan testing, and electrical safety inspections to ensure consistent quality.

Yes, through optimized winding design, precision bearings, and advanced control algorithms, BLDC motors can be tailored for ultra-quiet operation.

Prototype development usually takes 2–4 weeks, while mass production lead times range from 4–8 weeks depending on customization complexity.

Factory customization ensures the brushless DC motor is perfectly matched to the application, improving efficiency, reliability, system integration, and overall cost-effectiveness.