- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

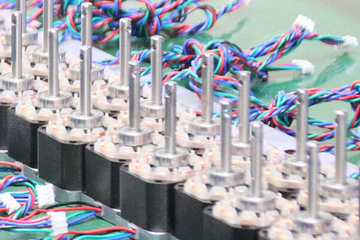

Changzhou LeanMotor Co., Ltd is a professional stepper motor & brushless dc motor manufacturer with 15years manufacturing experience, Our company specialises in the production of all kinds of hybrid stepper motors, linear motions, dc brushless motors, integrated servo motors and related drives, with an annual output of more than 2 million units, in addition, we have several cooperative factories specialising in the production of all kinds of permanent magnet stepping motors, brushed DC motors, 2 phase and 3 phase AC motors, gearboxes, encoders, brakes, etc. Our products are exported to more than 30 countries and regions, such as the United States, Germany, Switzerland, Italy, France and so on.

LeanMotor's stepper motors cover 2phase or 3phase hybrid stepper motors, motor size including nema 8 11 14 16 17 23 24 34 42 52 step motors, and we also have many excellent suppliers providing gearbox, brake, encoder or other motor related parts.

Our all products passed CE Rohs, Reach, ISO 9001 and ISO14001 certificated. We can professionally customize and provide customized services for all the needs of our customers for the use of stepper motors.

Providing high quality OEM ODM customized service, motor customized including wires, shafts, motor parameters, covers and so on. Related parts cover

—— 15 Years Experience of Stepper Motor & Brushless Dc Motor Manufacturing ——

Title: Classification of Stepper MotorsStepper motors are widely used in various industries for their precise control and positioning capabilities. Among the different types of stepper motors available, the LeanMotor brand offers a range of options suitable for diverse applications. In this article,

Title: The Working Principle of Stepper Motors by LeanMotorStepper motors are a fascinating and essential component in various industries, providing precise control over rotational motion. Among the leading brands in this field, LeanMotor stands out as a reliable and innovative provider of stepper m

What is a Stepper Motor?A stepper motor is a type of electromechanical device that converts electrical pulses into precise mechanical movement. Unlike conventional motors that rotate continuously when powered, a stepper motor moves in discrete steps, meaning it rotates in fixed angles (called steps)

A brake stepper motor is a stepper motor equipped with an electromagnetic brake that holds the motor shaft in position when power is off, preventing unwanted movement.

Key advantages include secure position holding, enhanced safety, load stability during power loss, reduced system wear, and improved reliability.

The brake is typically power-off engaged and power-on released, meaning it automatically locks the shaft when power is removed.

Brake stepper motors are widely used in vertical axis systems, medical equipment, automation machinery, robotics, packaging machines, and lifting mechanisms.

No, the brake holds the position without affecting the stepping accuracy or repeatability of the motor during normal operation.

Brake holding torque varies by motor size and brake type and can range from a few N·cm to several N·m.

Yes, brake stepper motors are ideal for vertical loads because the brake prevents load drop during power-off conditions.

The brake only consumes power during release, so heat generation is minimal compared to continuously energized holding torque.

Yes, brake stepper motors fully support microstepping and smooth motion control.

Brake stepper motors are commonly available in NEMA 17, NEMA 23, NEMA 24, and NEMA 34 frame sizes.

Yes, manufacturers can customize brake holding torque to match application load and safety requirements.

Yes, different electromagnetic brake designs can be selected based on voltage, response time, and durability needs.

Yes, brake stepper motors can be integrated with planetary gearboxes, linear actuators, or lead screws for enhanced performance.

Yes, incremental or absolute encoders can be added to create closed-loop brake stepper motor solutions.

Yes, shaft types such as single shaft, double shaft, D-cut, hollow shaft, or custom-machined shafts are available.

Yes, optimization of motor windings and brake materials can reduce noise and vibration.

Yes, cable length, connector type, and pin configuration can be tailored for easy system integration.

Yes, insulation class, sealing, and surface coatings can be customized for high-temperature, dusty, or humid environments.

Each brake stepper motor undergoes brake torque testing, endurance testing, insulation testing, and functional inspection.

Standard brake stepper motors are often available quickly, while customized versions typically require 3–6 weeks, depending on design complexity.