- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 2.8A

Resistance: 0.9 -2.2Ω

Rated Torque: 700-1200 g.cm

| Availability: | |

|---|---|

| Quantity: | |

Nema24 Geared Stepper Motor with HPS60 Series High Precision Planetary Gearbox

LeanMotor

Gearbox Motors

Nema23 (57mm)

4wires, 6wires

2 Phase, 3 Phase

0.9°, 1.2°, 1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 75N (20mm from the flange) |

| Max. axial force | 15N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| (L)mm | A | Ω | mH | N.m | No. | g.cm | g.cm2 | Kg | ||

| LM60HS56-2804 | 1.8 | 56 | 2.8 | 0.9 | 3.6 | 1.65 | 4 | 700 | 300 | 0.77 |

| LM60HS67-2804 | 1.8 | 67 | 2.8 | 1.2 | 4.6 | 2.1 | 4 | 900 | 570 | 1.2 |

| LM60HS88-2804 | 1.8 | 88 | 2.8 | 1.5 | 6.8 | 3.1 | 4 | 1000 | 840 | 1.4 |

| LM60HS100-2804 | 1.8 | 100 | 2.8 | 1.6 | 6.4 | 4 | 4 | 1100 | 980 | 1.7 |

| LM60HS111-2804 | 1.8 | 111 | 2.8 | 2.2 | 8.3 | 4.5 | 4 | 1200 | 1120 | 1.9 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 75N (20mm from the flange) |

| Max. axial force | 15N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| (L)mm | A | Ω | mH | N.m | No. | g.cm | g.cm2 | Kg | ||

| LM60HS56-2804 | 1.8 | 56 | 2.8 | 0.9 | 3.6 | 1.65 | 4 | 700 | 300 | 0.77 |

| LM60HS67-2804 | 1.8 | 67 | 2.8 | 1.2 | 4.6 | 2.1 | 4 | 900 | 570 | 1.2 |

| LM60HS88-2804 | 1.8 | 88 | 2.8 | 1.5 | 6.8 | 3.1 | 4 | 1000 | 840 | 1.4 |

| LM60HS100-2804 | 1.8 | 100 | 2.8 | 1.6 | 6.4 | 4 | 4 | 1100 | 980 | 1.7 |

| LM60HS111-2804 | 1.8 | 111 | 2.8 | 2.2 | 8.3 | 4.5 | 4 | 1200 | 1120 | 1.9 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

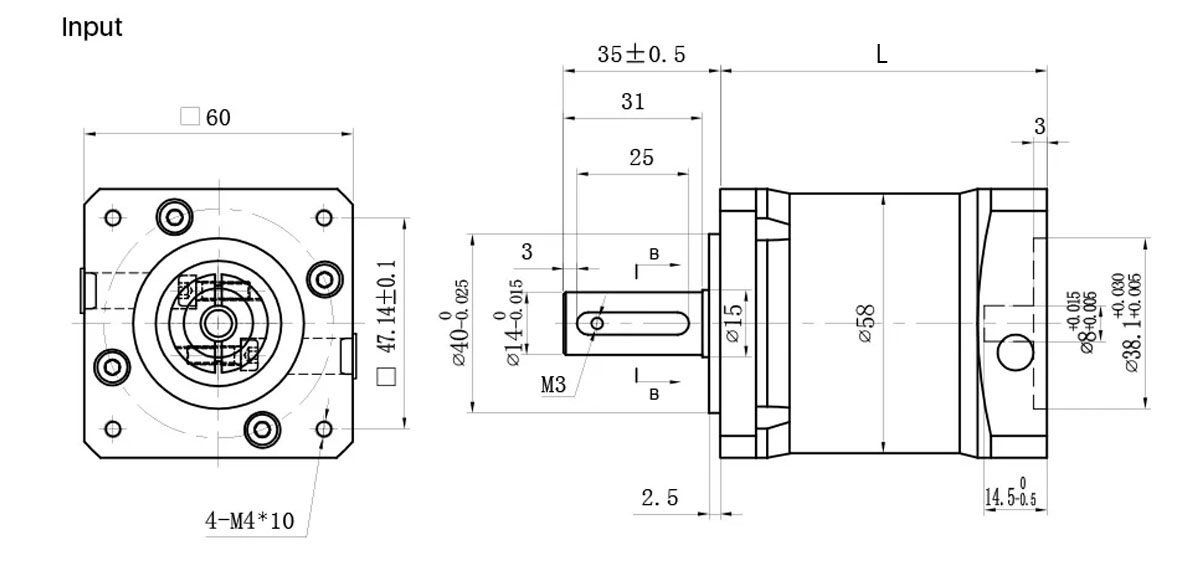

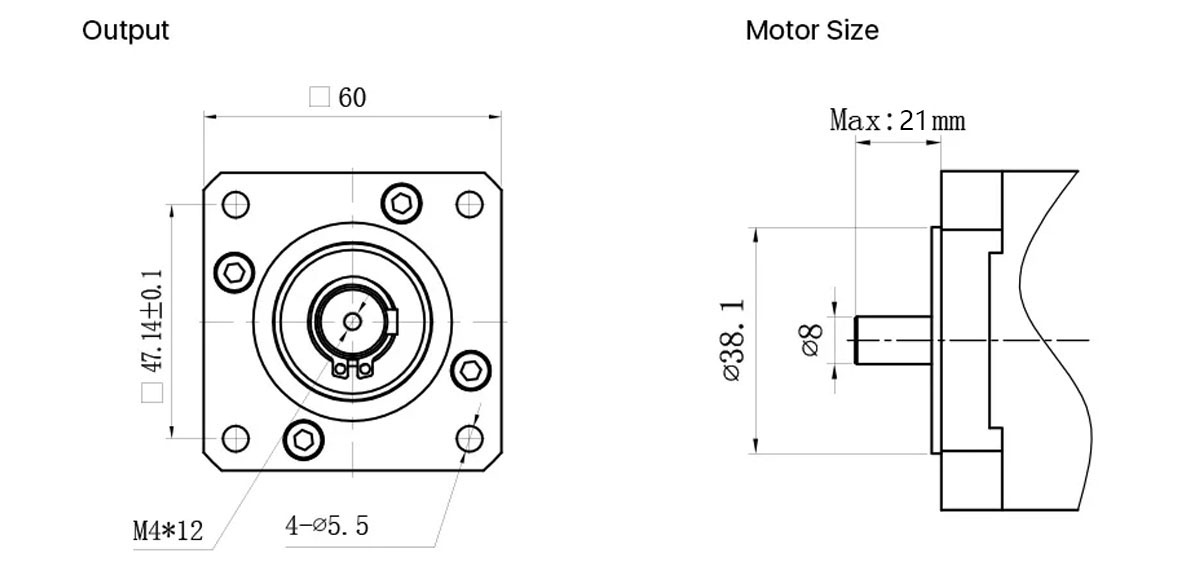

| Model | / | LM-HPS60-L1 | LM-HPS60-L2 | |||||||||||||

| Gear Ratio | / | 3 | 4 | 5 | 7 | 10 | 16 | 20 | 25 | 28 | 30 | 35 | 40 | 50 | 70 | 100 |

| Gear Trains | / | 1 | 2 | |||||||||||||

| Gearbox Length | mm | 92 | 108 | |||||||||||||

| Rated Torque | N.m | 16 | 25 | 28 | 20 | 10 | 30 | 30 | 32 | 30 | 30 | 30 | 25 | 25 | 20 | 10 |

| Sundden Stop Torque | N.m | 32 | 50 | 56 | 40 | 20 | 60 | 60 | 64 | 60 | 60 | 60 | 50 | 50 | 40 | 20 |

| Back Lash | arcmin | ≤15 arcmin | ≤20 arcmin | |||||||||||||

| Efficiency | % | 96 | 94 | |||||||||||||

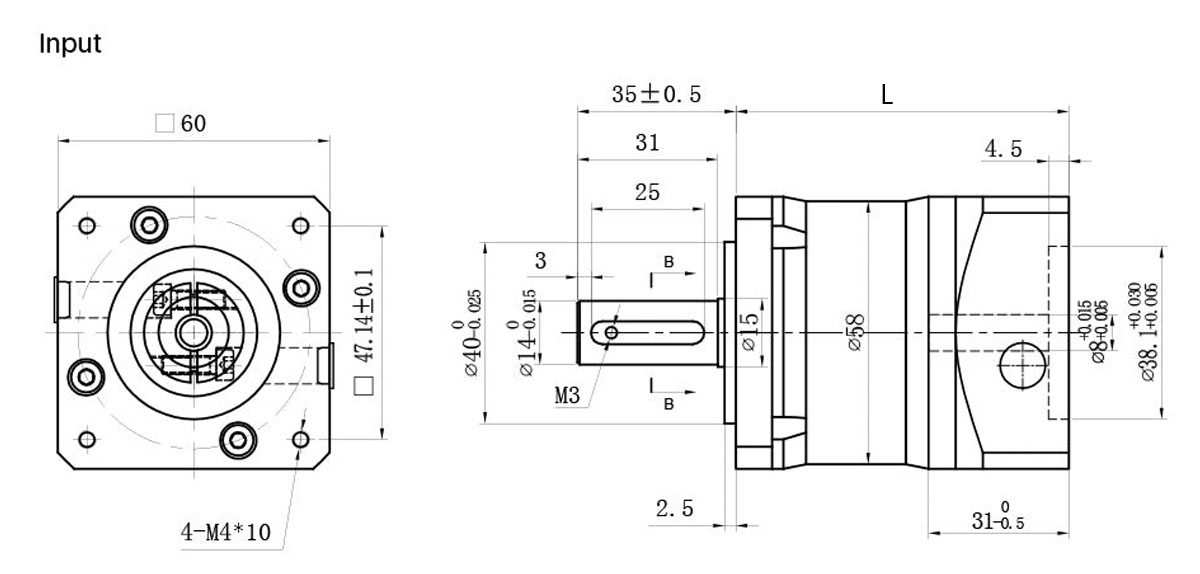

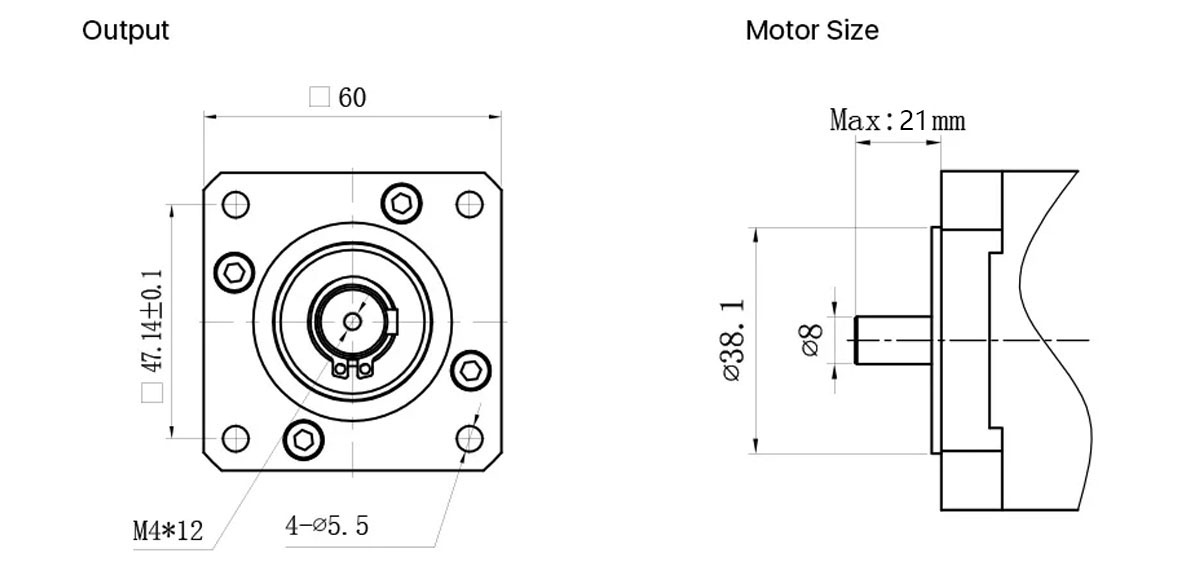

| Suitable Motor Dimension | mm | Φ8-14 / Φ38.1-2/ F47.14-M4 | Φ8-14 / Φ38.1-2 / F47.14-M4 | |||||||||||||

| Rated Input Speed | Rpm | 3000 | 3000 | |||||||||||||

| Max Input Speed | Rpm | 6000 | 6000 | |||||||||||||

| Average Life Span | h | 20000 | 20000 | |||||||||||||

| Axial Force | N | 230 | 230 | |||||||||||||

| Radial Force | N | 400 | 400 | |||||||||||||

| Noise | dB | ≤65 | ≤65 | |||||||||||||

| Protection Level | IP | IP54 | IP54 | |||||||||||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||||||||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||||||||||

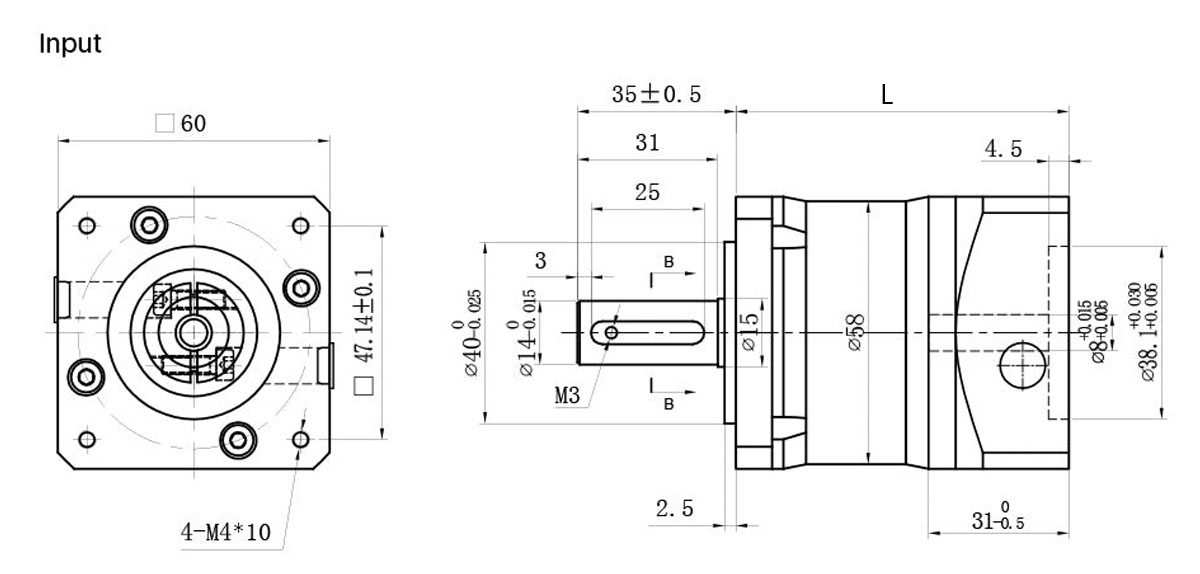

| Model | / | LM-HPS60-L1SW | LM-HPS60-L2SW | |||||||||||||

| Gear Ratio | / | 3 | 4 | 5 | 7 | 10 | 16 | 20 | 25 | 28 | 30 | 35 | 40 | 50 | 70 | 100 |

| Gear Trains | / | 1 | 2 | |||||||||||||

| Gearbox Length | mm | 108.5 | 124.5 | |||||||||||||

| Rated Torque | N.m | 16 | 25 | 28 | 20 | 10 | 30 | 30 | 32 | 30 | 30 | 30 | 25 | 25 | 20 | 10 |

| Sundden Stop Torque | N.m | 32 | 50 | 56 | 40 | 20 | 60 | 60 | 64 | 60 | 60 | 60 | 50 | 50 | 40 | 20 |

| Back Lash | arcmin | ≤15 arcmin | ≤20 arcmin | |||||||||||||

| Efficiency | % | 96 | 94 | |||||||||||||

| Suitable Motor Dimension | mm | Φ8-30/ Φ38.1-2/ F47.14-M4 | Φ8-30 / Φ38.1-2 / F47.14-M4 | |||||||||||||

| Rated Input Speed | Rpm | 3000 | 3000 | |||||||||||||

| Max Input Speed | Rpm | 6000 | 6000 | |||||||||||||

| Average Life Span | h | 20000 | 20000 | |||||||||||||

| Axial Force | N | 230 | 230 | |||||||||||||

| Radial Force | N | 400 | 400 | |||||||||||||

| Noise | dB | ≤65 | ≤65 | |||||||||||||

| Protection Level | IP | IP54 | IP54 | |||||||||||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||||||||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||||||||||

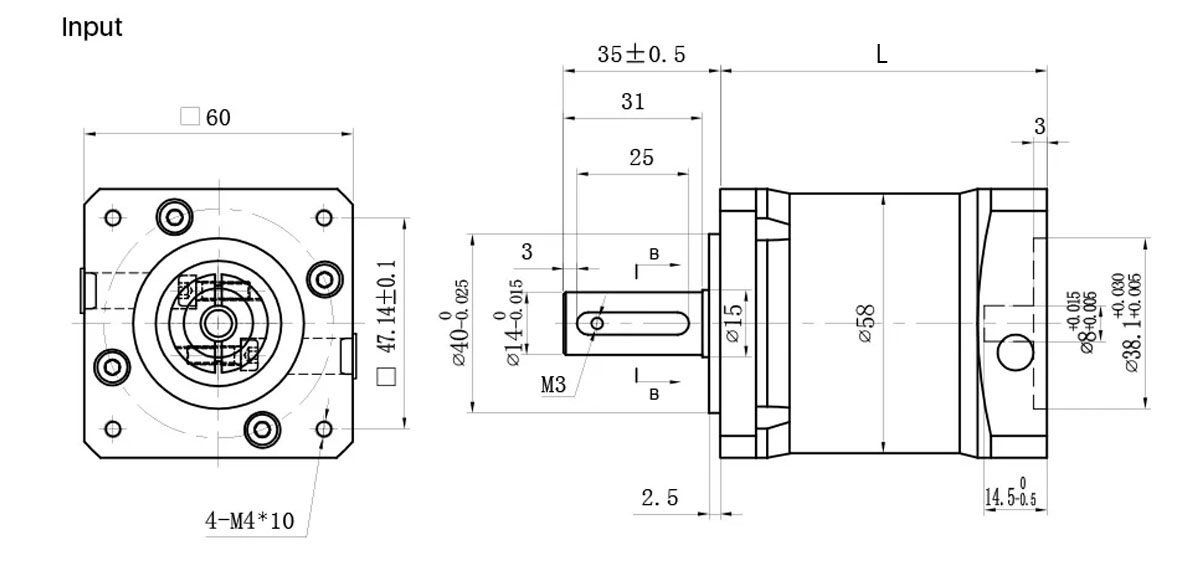

| Model | / | LM-HPS60-L1 | LM-HPS60-L2 | |||||||||||||

| Gear Ratio | / | 3 | 4 | 5 | 7 | 10 | 16 | 20 | 25 | 28 | 30 | 35 | 40 | 50 | 70 | 100 |

| Gear Trains | / | 1 | 2 | |||||||||||||

| Gearbox Length | mm | 92 | 108 | |||||||||||||

| Rated Torque | N.m | 16 | 25 | 28 | 20 | 10 | 30 | 30 | 32 | 30 | 30 | 30 | 25 | 25 | 20 | 10 |

| Sundden Stop Torque | N.m | 32 | 50 | 56 | 40 | 20 | 60 | 60 | 64 | 60 | 60 | 60 | 50 | 50 | 40 | 20 |

| Back Lash | arcmin | ≤15 arcmin | ≤20 arcmin | |||||||||||||

| Efficiency | % | 96 | 94 | |||||||||||||

| Suitable Motor Dimension | mm | Φ8-14 / Φ38.1-2/ F47.14-M4 | Φ8-14 / Φ38.1-2 / F47.14-M4 | |||||||||||||

| Rated Input Speed | Rpm | 3000 | 3000 | |||||||||||||

| Max Input Speed | Rpm | 6000 | 6000 | |||||||||||||

| Average Life Span | h | 20000 | 20000 | |||||||||||||

| Axial Force | N | 230 | 230 | |||||||||||||

| Radial Force | N | 400 | 400 | |||||||||||||

| Noise | dB | ≤65 | ≤65 | |||||||||||||

| Protection Level | IP | IP54 | IP54 | |||||||||||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||||||||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||||||||||

| Model | / | LM-HPS60-L1SW | LM-HPS60-L2SW | |||||||||||||

| Gear Ratio | / | 3 | 4 | 5 | 7 | 10 | 16 | 20 | 25 | 28 | 30 | 35 | 40 | 50 | 70 | 100 |

| Gear Trains | / | 1 | 2 | |||||||||||||

| Gearbox Length | mm | 108.5 | 124.5 | |||||||||||||

| Rated Torque | N.m | 16 | 25 | 28 | 20 | 10 | 30 | 30 | 32 | 30 | 30 | 30 | 25 | 25 | 20 | 10 |

| Sundden Stop Torque | N.m | 32 | 50 | 56 | 40 | 20 | 60 | 60 | 64 | 60 | 60 | 60 | 50 | 50 | 40 | 20 |

| Back Lash | arcmin | ≤15 arcmin | ≤20 arcmin | |||||||||||||

| Efficiency | % | 96 | 94 | |||||||||||||

| Suitable Motor Dimension | mm | Φ8-30/ Φ38.1-2/ F47.14-M4 | Φ8-30 / Φ38.1-2 / F47.14-M4 | |||||||||||||

| Rated Input Speed | Rpm | 3000 | 3000 | |||||||||||||

| Max Input Speed | Rpm | 6000 | 6000 | |||||||||||||

| Average Life Span | h | 20000 | 20000 | |||||||||||||

| Axial Force | N | 230 | 230 | |||||||||||||

| Radial Force | N | 400 | 400 | |||||||||||||

| Noise | dB | ≤65 | ≤65 | |||||||||||||

| Protection Level | IP | IP54 | IP54 | |||||||||||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||||||||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||||||||||

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

It is a compact stepper motor with a NEMA 24 frame size, integrated with a planetary gearbox for increased torque, precision, and stability in positioning applications.

Planetary gears provide higher torque, better efficiency, smoother motion, reduced backlash, and improved repeatability compared to standard stepper motors.

Standard NEMA 24 motors usually have a 1.8° step angle, providing 200 steps per revolution, but microstepping can achieve even higher positioning resolution.

Torque depends on the gearbox ratio and motor specification. Planetary gears significantly increase output torque, often by 3–10× compared to a direct-drive motor.

They are widely used in CNC machines, 3D printers, medical devices, automation equipment, robotics, and packaging machinery.

Yes, the combination of precise motor steps and low-backlash planetary gearing ensures accurate, repeatable positioning for demanding tasks.

Yes, when properly cooled and operated within rated current and torque limits, these motors can run continuously with high reliability.

They can be driven using standard stepper drivers, microstepping controllers, and digital motion controllers depending on application precision requirements.

Speed depends on voltage, current, and gearbox ratio. Higher gear ratios increase torque but reduce maximum speed.

Planetary geared stepper motors are efficient at converting electrical energy into torque, and high-precision gearing reduces energy losses due to mechanical inefficiency.

Yes, gear ratios, winding types, and current ratings can be adjusted to meet specific torque and speed demands.

Factories typically offer a range of ratios, commonly from 3:1 to 100:1, depending on precision and torque requirements.

Yes, incremental or absolute encoders can be added for closed-loop position feedback and higher system accuracy.

Yes, options include different shaft diameters, lengths, flat or D-shaped shafts, and custom mounting flange configurations.

Yes, precision gears, vibration-damping construction, and optimized current control can significantly reduce operational noise.

Custom enclosures and sealing can provide IP54, IP65, or higher ratings for motors operating in harsh environments.

Yes, most factories offer OEM and ODM services, including motor design, labeling, and integration into customer systems.

Prototyping usually takes 2–4 weeks, while mass production ranges from 4–8 weeks depending on complexity and quantity.

Motors undergo torque tests, step accuracy tests, insulation resistance tests, and thermal performance checks to ensure consistent quality.

Customizing gearing, torque, step angle, shaft design, and optional sensors ensures the motor fits the application perfectly, enhancing efficiency, lifespan, and system reliability.

It is a compact stepper motor with a NEMA 24 frame size, integrated with a planetary gearbox for increased torque, precision, and stability in positioning applications.

Planetary gears provide higher torque, better efficiency, smoother motion, reduced backlash, and improved repeatability compared to standard stepper motors.

Standard NEMA 24 motors usually have a 1.8° step angle, providing 200 steps per revolution, but microstepping can achieve even higher positioning resolution.

Torque depends on the gearbox ratio and motor specification. Planetary gears significantly increase output torque, often by 3–10× compared to a direct-drive motor.

They are widely used in CNC machines, 3D printers, medical devices, automation equipment, robotics, and packaging machinery.

Yes, the combination of precise motor steps and low-backlash planetary gearing ensures accurate, repeatable positioning for demanding tasks.

Yes, when properly cooled and operated within rated current and torque limits, these motors can run continuously with high reliability.

They can be driven using standard stepper drivers, microstepping controllers, and digital motion controllers depending on application precision requirements.

Speed depends on voltage, current, and gearbox ratio. Higher gear ratios increase torque but reduce maximum speed.

Planetary geared stepper motors are efficient at converting electrical energy into torque, and high-precision gearing reduces energy losses due to mechanical inefficiency.

Yes, gear ratios, winding types, and current ratings can be adjusted to meet specific torque and speed demands.

Factories typically offer a range of ratios, commonly from 3:1 to 100:1, depending on precision and torque requirements.

Yes, incremental or absolute encoders can be added for closed-loop position feedback and higher system accuracy.

Yes, options include different shaft diameters, lengths, flat or D-shaped shafts, and custom mounting flange configurations.

Yes, precision gears, vibration-damping construction, and optimized current control can significantly reduce operational noise.

Custom enclosures and sealing can provide IP54, IP65, or higher ratings for motors operating in harsh environments.

Yes, most factories offer OEM and ODM services, including motor design, labeling, and integration into customer systems.

Prototyping usually takes 2–4 weeks, while mass production ranges from 4–8 weeks depending on complexity and quantity.

Motors undergo torque tests, step accuracy tests, insulation resistance tests, and thermal performance checks to ensure consistent quality.

Customizing gearing, torque, step angle, shaft design, and optional sensors ensures the motor fits the application perfectly, enhancing efficiency, lifespan, and system reliability.