- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 6.0A

Resistance: 0.37Ω

Rated Torque: 4.6N.m(651.41oz.in)

| Availability: | |

|---|---|

| Quantity: | |

Nema34 Geared Stepper Motor with HPS90 Series High Precision Planetary Gearbox

LeanMotor

Gearbox Motors

Nema24 (60mm)

4wires, 6wires

2 Phase, 3 Phase

0.9°, 1.2°, 1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° or 1.2° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 820VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 220N (20mm from the flange) |

| Max. axial force | 60N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | Kg.cm | g.cm2 | Kg | |

| LM86HS68-5904 | 1.8 | 67 | 5.9 | 0.28 | 1.7 | 3.4 | 4 | 0.8 | 1000 | 1.7 |

| LM86HS68-2808 | 1.8 | 67 | 2.8 | 1.4 | 3.9 | 3.4 | 8 | 0.8 | 1000 | 1.7 |

| LM86HS78-5504 | 1.8 | 78 | 5.5 | 0.46 | 4 | 4.6 | 4 | 1.2 | 1400 | 2.3 |

| LM86HS78-4208 | 1.8 | 78 | 4.2 | 0.75 | 3.4 | 4.6 | 8 | 1.2 | 1400 | 2.3 |

| LM86HS97-4504 | 1.8 | 97 | 4.5 | 0.66 | 3 | 5.8 | 4 | 1.7 | 2100 | 3 |

| LM86HS97-4008 | 1.8 | 97 | 4 | 0.98 | 4.1 | 4.7 | 8 | 1.7 | 2100 | 3 |

| LM86HS100-6004 | 1.8 | 100 | 6 | 0.36 | 2.8 | 7 | 4 | 1.9 | 2200 | 3.1 |

| LM86HS115-6004 | 1.8 | 115 | 6 | 0.6 | 6.5 | 8.7 | 4 | 2.4 | 2700 | 3.8 |

| LM86HS115-4208 | 1.8 | 115 | 4.2 | 0.9 | 6 | 8.7 | 8 | 2.4 | 2700 | 3.8 |

| LM86HS126-6004 | 1.8 | 126 | 6 | 0.58 | 6.5 | 6.3 | 4 | 2.9 | 3200 | 4.5 |

| LM86HS155-6004 | 1.8 | 155 | 6 | 0.68 | 9 | 13 | 4 | 3.6 | 4000 | 5.4 |

| LM86HS155-4208 | 1.8 | 155 | 4.2 | 1.25 | 8 | 12.2 | 8 | 3.6 | 4000 | 5.4 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm | g.cm2 | Kg | |

| LM86HY62-5904 | 1.8 | 62 | 5.9 | 0.23 | 1.5 | 1.8 | 4 | 0.8 | 560 | 1.5 |

| LM86HY94-4006 | 1.8 | 94 | 4 | 0.75 | 4.5 | 2.6 | 6 | 2.4 | 1100 | 2.6 |

| LM86HY94-5604 | 1.8 | 94 | 5.6 | 0.38 | 3.9 | 3.5 | 4 | 2.4 | 1100 | 2.6 |

| LM86HY134-6706 | 1.8 | 134 | 6.7 | 0.45 | 2 | 3.6 | 6 | 3.6 | 1800 | 3.6 |

| LM86HY134-5604 | 1.8 | 134 | 5.6 | 0.63 | 6.6 | 5 | 4 | 3.6 | 1800 | 3.6 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | g.cm2 | Kg | |

| LM86H3P65-3006 | 1.2 | 65 | 3 | 0.5 | 1.6 | 2 | 1100 | 1.65 |

| LM86H3P98-5206 | 1.2 | 98 | 5.2 | 0.6 | 3 | 4.5 | 2320 | 2.7 |

| LM86H3P113-5206 | 1.2 | 113 | 5.2 | 0.9 | 5.9 | 6 | 3100 | 3.5 |

| LM86H3P126-6006 | 1.2 | 126 | 6 | 0.75 | 2.4 | 6 | 3300 | 3.8 |

| LM86H3P150-5006 | 1.2 | 150 | 5 | 1.5 | 3 | 7 | 4650 | 5.1 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° or 1.2° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 820VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 220N (20mm from the flange) |

| Max. axial force | 60N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | Kg.cm | g.cm2 | Kg | |

| LM86HS68-5904 | 1.8 | 67 | 5.9 | 0.28 | 1.7 | 3.4 | 4 | 0.8 | 1000 | 1.7 |

| LM86HS68-2808 | 1.8 | 67 | 2.8 | 1.4 | 3.9 | 3.4 | 8 | 0.8 | 1000 | 1.7 |

| LM86HS78-5504 | 1.8 | 78 | 5.5 | 0.46 | 4 | 4.6 | 4 | 1.2 | 1400 | 2.3 |

| LM86HS78-4208 | 1.8 | 78 | 4.2 | 0.75 | 3.4 | 4.6 | 8 | 1.2 | 1400 | 2.3 |

| LM86HS97-4504 | 1.8 | 97 | 4.5 | 0.66 | 3 | 5.8 | 4 | 1.7 | 2100 | 3 |

| LM86HS97-4008 | 1.8 | 97 | 4 | 0.98 | 4.1 | 4.7 | 8 | 1.7 | 2100 | 3 |

| LM86HS100-6004 | 1.8 | 100 | 6 | 0.36 | 2.8 | 7 | 4 | 1.9 | 2200 | 3.1 |

| LM86HS115-6004 | 1.8 | 115 | 6 | 0.6 | 6.5 | 8.7 | 4 | 2.4 | 2700 | 3.8 |

| LM86HS115-4208 | 1.8 | 115 | 4.2 | 0.9 | 6 | 8.7 | 8 | 2.4 | 2700 | 3.8 |

| LM86HS126-6004 | 1.8 | 126 | 6 | 0.58 | 6.5 | 6.3 | 4 | 2.9 | 3200 | 4.5 |

| LM86HS155-6004 | 1.8 | 155 | 6 | 0.68 | 9 | 13 | 4 | 3.6 | 4000 | 5.4 |

| LM86HS155-4208 | 1.8 | 155 | 4.2 | 1.25 | 8 | 12.2 | 8 | 3.6 | 4000 | 5.4 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm | g.cm2 | Kg | |

| LM86HY62-5904 | 1.8 | 62 | 5.9 | 0.23 | 1.5 | 1.8 | 4 | 0.8 | 560 | 1.5 |

| LM86HY94-4006 | 1.8 | 94 | 4 | 0.75 | 4.5 | 2.6 | 6 | 2.4 | 1100 | 2.6 |

| LM86HY94-5604 | 1.8 | 94 | 5.6 | 0.38 | 3.9 | 3.5 | 4 | 2.4 | 1100 | 2.6 |

| LM86HY134-6706 | 1.8 | 134 | 6.7 | 0.45 | 2 | 3.6 | 6 | 3.6 | 1800 | 3.6 |

| LM86HY134-5604 | 1.8 | 134 | 5.6 | 0.63 | 6.6 | 5 | 4 | 3.6 | 1800 | 3.6 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | g.cm2 | Kg | |

| LM86H3P65-3006 | 1.2 | 65 | 3 | 0.5 | 1.6 | 2 | 1100 | 1.65 |

| LM86H3P98-5206 | 1.2 | 98 | 5.2 | 0.6 | 3 | 4.5 | 2320 | 2.7 |

| LM86H3P113-5206 | 1.2 | 113 | 5.2 | 0.9 | 5.9 | 6 | 3100 | 3.5 |

| LM86H3P126-6006 | 1.2 | 126 | 6 | 0.75 | 2.4 | 6 | 3300 | 3.8 |

| LM86H3P150-5006 | 1.2 | 150 | 5 | 1.5 | 3 | 7 | 4650 | 5.1 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

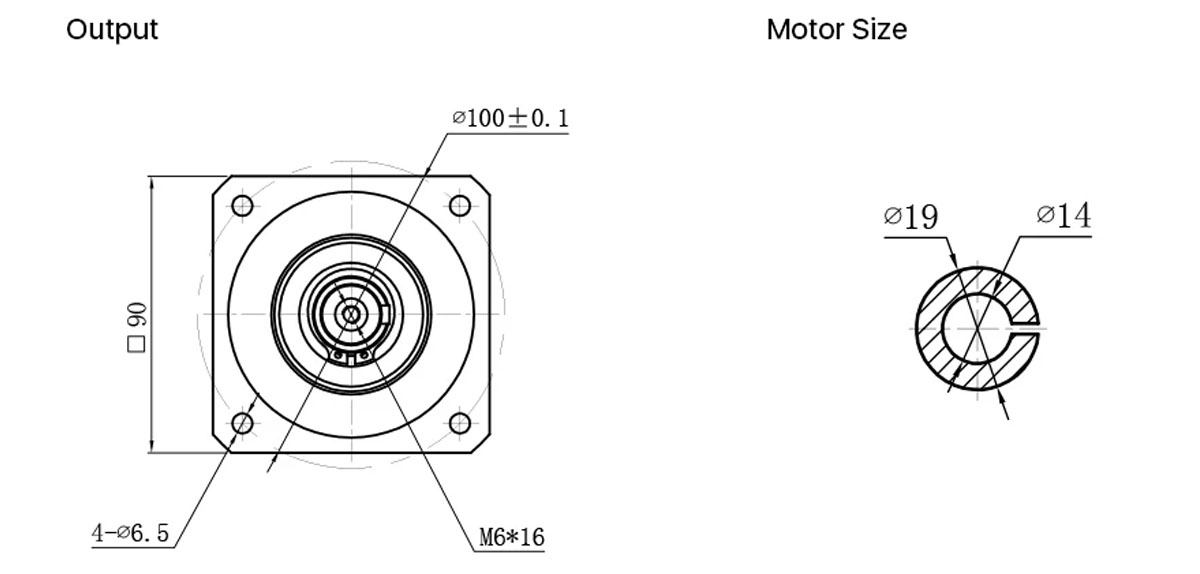

| Model | / | LM-HPS90-L1MB | |||

| Gear Ratio | / | 4 | 5 | 7 | 10 |

| Gear Trains | / | 1 | |||

| Gearbox Length | mm | 150 | |||

| Rated Torque | N.m | 80 | 90 | 60 | 39 |

| Sundden Stop Torque | N.m | 160 | 180 | 120 | 78 |

| Back Lash | arcmin | ≤10 arcmin | |||

| Efficiency | % | 96 | |||

| Suitable Motor Dimension | mm | Φ14-40 / Φ73-3 / F69.6-M5 | |||

| Rated Input Speed | Rpm | 3000 | |||

| Max Input Speed | Rpm | 6000 | |||

| Average Life Span | h | 20000 | |||

| Axial Force | N | 800 | |||

| Radial Force | N | 1000 | |||

| Noise | dB | ≤55 | |||

| Protection Level | IP | IP54 | |||

| Work Temp. | ℃ | -20 to +150 | |||

| Out Shaft Type | / | Key Shaft Type | |||

| Model | / | LM-HPS90-L2MB | |||||||

| Gear Ratio | / | 16 | 20 | 25 | 28 | 35 | 40 | 50 | 70 |

| Gear Trains | / | 2 | |||||||

| Gearbox Length | mm | 172.5 | |||||||

| Rated Torque | N.m | 90 | 90 | 100 | 90 | 100 | 90 | 100 | 70 |

| Sundden Stop Torque | N.m | 180 | 180 | 200 | 180 | 200 | 180 | 200 | 140 |

| Back Lash | arcmin | ≤15 arcmin | |||||||

| Efficiency | % | 94 | |||||||

| Suitable Motor Dimension | mm | Φ14-40 / Φ73-3 / F69.6-M5 | |||||||

| Rated Input Speed | Rpm | 3000 | |||||||

| Max Input Speed | Rpm | 6000 | |||||||

| Average Life Span | h | 20000 | |||||||

| Axial Force | N | 800 | |||||||

| Radial Force | N | 1000 | |||||||

| Noise | dB | ≤55 | |||||||

| Protection Level | IP | IP54 | |||||||

| Work Temp. | ℃ | -20 to +150 | |||||||

| Out Shaft Type | / | Key Shaft Type | |||||||

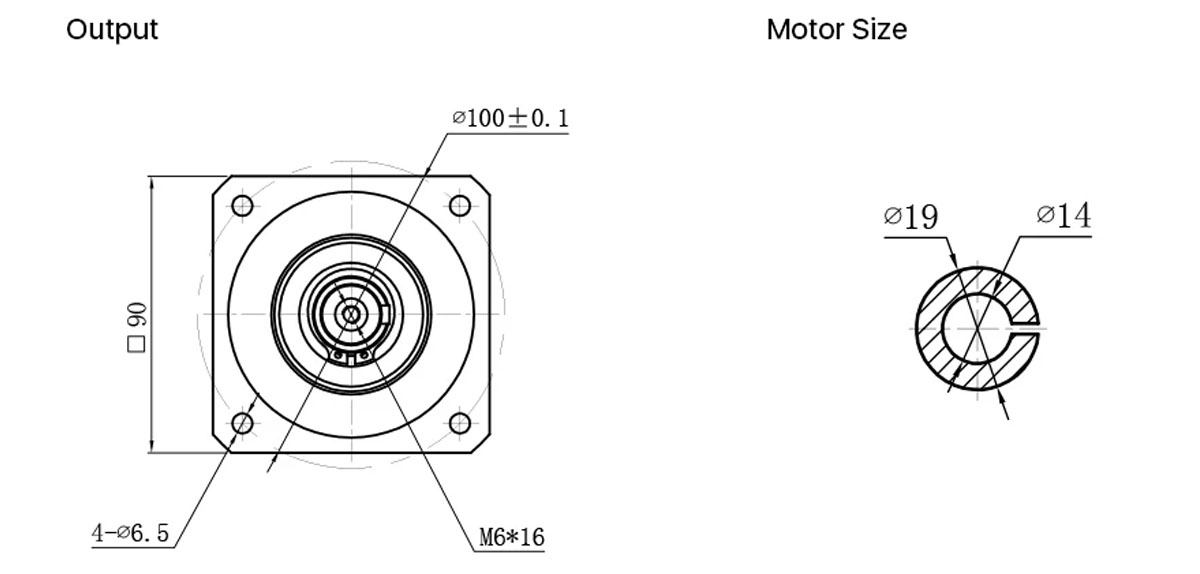

| Model | / | LM-HPS90-L1MB | |||

| Gear Ratio | / | 4 | 5 | 7 | 10 |

| Gear Trains | / | 1 | |||

| Gearbox Length | mm | 150 | |||

| Rated Torque | N.m | 80 | 90 | 60 | 39 |

| Sundden Stop Torque | N.m | 160 | 180 | 120 | 78 |

| Back Lash | arcmin | ≤10 arcmin | |||

| Efficiency | % | 96 | |||

| Suitable Motor Dimension | mm | Φ14-40 / Φ73-3 / F69.6-M5 | |||

| Rated Input Speed | Rpm | 3000 | |||

| Max Input Speed | Rpm | 6000 | |||

| Average Life Span | h | 20000 | |||

| Axial Force | N | 800 | |||

| Radial Force | N | 1000 | |||

| Noise | dB | ≤55 | |||

| Protection Level | IP | IP54 | |||

| Work Temp. | ℃ | -20 to +150 | |||

| Out Shaft Type | / | Key Shaft Type | |||

| Model | / | LM-HPS90-L2MB | |||||||

| Gear Ratio | / | 16 | 20 | 25 | 28 | 35 | 40 | 50 | 70 |

| Gear Trains | / | 2 | |||||||

| Gearbox Length | mm | 172.5 | |||||||

| Rated Torque | N.m | 90 | 90 | 100 | 90 | 100 | 90 | 100 | 70 |

| Sundden Stop Torque | N.m | 180 | 180 | 200 | 180 | 200 | 180 | 200 | 140 |

| Back Lash | arcmin | ≤15 arcmin | |||||||

| Efficiency | % | 94 | |||||||

| Suitable Motor Dimension | mm | Φ14-40 / Φ73-3 / F69.6-M5 | |||||||

| Rated Input Speed | Rpm | 3000 | |||||||

| Max Input Speed | Rpm | 6000 | |||||||

| Average Life Span | h | 20000 | |||||||

| Axial Force | N | 800 | |||||||

| Radial Force | N | 1000 | |||||||

| Noise | dB | ≤55 | |||||||

| Protection Level | IP | IP54 | |||||||

| Work Temp. | ℃ | -20 to +150 | |||||||

| Out Shaft Type | / | Key Shaft Type | |||||||

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

(NEMA 34 / 86BLS Geared Brushless DC Motor)

1. What is a NEMA 34 geared brushless DC motor used for?

A NEMA 34 geared BLDC motor is used in high-torque industrial applications such as automation machinery, conveyors, AGVs, packaging equipment, CNC auxiliary axes, and robotic systems.

2. What are the advantages of a geared BLDC motor compared to a standard BLDC motor?

The gearbox increases output torque, improves load handling, reduces speed, and allows the motor to operate in its optimal efficiency range.

3. What does NEMA 34 (86BLS) mean?

NEMA 34 refers to an 86 × 86 mm mounting frame size, suitable for medium- to high-power industrial motion control applications.

4. What types of gearboxes are available for this motor?

The motor can be equipped with planetary or other precision gearboxes, depending on torque, backlash, and lifespan requirements.

5. How does the gearbox affect motor torque and speed?

The gearbox multiplies output torque while proportionally reducing output speed, making it ideal for heavy-load, low-speed applications.

6. Is the NEMA 34 geared BLDC motor suitable for continuous operation?

Yes, it is designed for continuous industrial operation with high efficiency and stable thermal performance.

7. Does the motor support Hall sensor feedback?

Yes, Hall sensors provide accurate commutation and stable speed control, especially under varying load conditions.

8. What control methods are supported for this geared BLDC motor?

It supports standard BLDC control modes such as speed control, torque control, and direction control via compatible drivers.

9. What are the key benefits of using a brushless motor in geared applications?

Brushless motors offer higher efficiency, longer service life, lower maintenance, and quieter operation compared to brushed motors.

10. What industries commonly use NEMA 34 geared BLDC motors?

Common industries include industrial automation, logistics, robotics, medical equipment, energy systems, and intelligent manufacturing.

11. Can Lean Motor customize the gear ratio for this BLDC motor?

Yes, gear ratios can be customized to meet specific torque, speed, and load requirements.

12. Is it possible to customize output shaft size and configuration?

Output shaft diameter, length, keyway, and other mechanical features can be customized.

13. Can the BLDC motor winding be customized for voltage or speed requirements?

Lean Motor can customize winding parameters to match different voltage levels, speed ranges, and efficiency targets.

14. Are different gearbox types or precision grades available?

Yes, gearboxes with different backlash levels, materials, and precision classes are available.

15. Can encoders or feedback devices be integrated?

Encoders and other feedback devices can be integrated to support closed-loop control and precise positioning.

16. Is thermal management customization available for high-load applications?

The factory can optimize housing design, heat dissipation, and materials for demanding duty cycles.

17. Does Lean Motor support OEM or private labeling services?

Yes, OEM branding, custom nameplates, and packaging are available for distributors and system integrators.

18. Can this motor be supplied as an integrated motor-gearbox-driver solution?

Lean Motor can provide integrated BLDC motor, gearbox, and driver solutions to simplify system design.

19. Is low-MOQ or prototype customization supported?

Yes, the factory supports small-batch orders and prototype development for testing and validation.

20. What technical support is provided for customized NEMA 34 geared BLDC motors?

Lean Motor offers comprehensive technical support, including motor selection, drawings, performance testing, and after-sales service.

(NEMA 34 / 86BLS Geared Brushless DC Motor)

1. What is a NEMA 34 geared brushless DC motor used for?

A NEMA 34 geared BLDC motor is used in high-torque industrial applications such as automation machinery, conveyors, AGVs, packaging equipment, CNC auxiliary axes, and robotic systems.

2. What are the advantages of a geared BLDC motor compared to a standard BLDC motor?

The gearbox increases output torque, improves load handling, reduces speed, and allows the motor to operate in its optimal efficiency range.

3. What does NEMA 34 (86BLS) mean?

NEMA 34 refers to an 86 × 86 mm mounting frame size, suitable for medium- to high-power industrial motion control applications.

4. What types of gearboxes are available for this motor?

The motor can be equipped with planetary or other precision gearboxes, depending on torque, backlash, and lifespan requirements.

5. How does the gearbox affect motor torque and speed?

The gearbox multiplies output torque while proportionally reducing output speed, making it ideal for heavy-load, low-speed applications.

6. Is the NEMA 34 geared BLDC motor suitable for continuous operation?

Yes, it is designed for continuous industrial operation with high efficiency and stable thermal performance.

7. Does the motor support Hall sensor feedback?

Yes, Hall sensors provide accurate commutation and stable speed control, especially under varying load conditions.

8. What control methods are supported for this geared BLDC motor?

It supports standard BLDC control modes such as speed control, torque control, and direction control via compatible drivers.

9. What are the key benefits of using a brushless motor in geared applications?

Brushless motors offer higher efficiency, longer service life, lower maintenance, and quieter operation compared to brushed motors.

10. What industries commonly use NEMA 34 geared BLDC motors?

Common industries include industrial automation, logistics, robotics, medical equipment, energy systems, and intelligent manufacturing.

11. Can Lean Motor customize the gear ratio for this BLDC motor?

Yes, gear ratios can be customized to meet specific torque, speed, and load requirements.

12. Is it possible to customize output shaft size and configuration?

Output shaft diameter, length, keyway, and other mechanical features can be customized.

13. Can the BLDC motor winding be customized for voltage or speed requirements?

Lean Motor can customize winding parameters to match different voltage levels, speed ranges, and efficiency targets.

14. Are different gearbox types or precision grades available?

Yes, gearboxes with different backlash levels, materials, and precision classes are available.

15. Can encoders or feedback devices be integrated?

Encoders and other feedback devices can be integrated to support closed-loop control and precise positioning.

16. Is thermal management customization available for high-load applications?

The factory can optimize housing design, heat dissipation, and materials for demanding duty cycles.

17. Does Lean Motor support OEM or private labeling services?

Yes, OEM branding, custom nameplates, and packaging are available for distributors and system integrators.

18. Can this motor be supplied as an integrated motor-gearbox-driver solution?

Lean Motor can provide integrated BLDC motor, gearbox, and driver solutions to simplify system design.

19. Is low-MOQ or prototype customization supported?

Yes, the factory supports small-batch orders and prototype development for testing and validation.

20. What technical support is provided for customized NEMA 34 geared BLDC motors?

Lean Motor offers comprehensive technical support, including motor selection, drawings, performance testing, and after-sales service.