- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 0.4 A-1.7A

Customized: Connectors, Gearbox, Encoder, Brake, Lead Screw, Integrated Driver...

| Availability: | |

|---|---|

| Quantity: | |

Nema 17 Worm Geared Stepper Motor

LeanMotor

Gearbox Motors

Nema17 (42mm)

4wires, 6wires

2 Phase

0.9°, 1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° or 0.9° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HM34-1334 | 0.9 | 34 | 1.33 | 2.1 | 4.2 | 2.2 | 4 | 200 | 35 | 0.22 |

| LM42HM40-1684 | 0.9 | 40 | 1.68 | 1.65 | 3.2 | 3.3 | 4 | 220 | 54 | 0.28 |

| LM42HM48-1684 | 0.9 | 48 | 1.68 | 1.65 | 4.1 | 4.4 | 4 | 250 | 68 | 0.38 |

| LM42HM60-1684 | 0.9 | 60 | 1.68 | 1.65 | 5 | 5.5 | 4 | 270 | 106 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HS25-0404 | 1.8 | 25 | 0.4 | 24 | 36 | 1.5 | 4 | 75 | 20 | 0.15 |

| LM42HS28-0504 | 1.8 | 28 | 0.5 | 20 | 21 | 1.8 | 4 | 85 | 24 | 0.22 |

| LM42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 120 | 34 | 0.22 |

| LM42HS34-0956 | 1.8 | 34 | 0.95 | 4.2 | 2.5 | 2.2 | 6 | 120 | 34 | 0.22 |

| LM42HS40-1704 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 150 | 54 | 0.28 |

| LM42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 3.2 | 6 | 150 | 54 | 0.28 |

| LM42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 5.5 | 4 | 260 | 68 | 0.38 |

| LM42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 4 | 6 | 260 | 68 | 0.38 |

| LM42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.55 |

| LM42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

| Item | Specifications |

| Step Angle | 1.8° or 0.9° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HM34-1334 | 0.9 | 34 | 1.33 | 2.1 | 4.2 | 2.2 | 4 | 200 | 35 | 0.22 |

| LM42HM40-1684 | 0.9 | 40 | 1.68 | 1.65 | 3.2 | 3.3 | 4 | 220 | 54 | 0.28 |

| LM42HM48-1684 | 0.9 | 48 | 1.68 | 1.65 | 4.1 | 4.4 | 4 | 250 | 68 | 0.38 |

| LM42HM60-1684 | 0.9 | 60 | 1.68 | 1.65 | 5 | 5.5 | 4 | 270 | 106 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | Kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM42HS25-0404 | 1.8 | 25 | 0.4 | 24 | 36 | 1.5 | 4 | 75 | 20 | 0.15 |

| LM42HS28-0504 | 1.8 | 28 | 0.5 | 20 | 21 | 1.8 | 4 | 85 | 24 | 0.22 |

| LM42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 120 | 34 | 0.22 |

| LM42HS34-0956 | 1.8 | 34 | 0.95 | 4.2 | 2.5 | 2.2 | 6 | 120 | 34 | 0.22 |

| LM42HS40-1704 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 150 | 54 | 0.28 |

| LM42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 3.2 | 6 | 150 | 54 | 0.28 |

| LM42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 5.5 | 4 | 260 | 68 | 0.38 |

| LM42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 4 | 6 | 260 | 68 | 0.38 |

| LM42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.55 |

| LM42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

(NEMA 17 Worm Geared Stepper Motor)

A NEMA 17 worm geared stepper motor is widely used in applications requiring high torque, precise positioning, and self-locking capability, such as automation equipment, valve control, medical devices, lifting mechanisms, and robotics.

Worm gearing provides high torque multiplication, compact structure, smooth operation, and a self-locking function that prevents back-driving.

NEMA 17 refers to a 1.7 × 1.7 inch (42 × 42 mm) motor mounting face, making it a standard size for industrial and automation applications.

Yes, worm gear reducers typically offer self-locking, allowing the motor to hold position even when power is off.

Multiple gear ratios are available to meet different torque and speed requirements, depending on the application.

The worm gearbox significantly increases output torque while reducing output speed, ideal for heavy-load and low-speed applications.

Yes, the self-locking feature makes it suitable for vertical movement and load-holding applications.

It maintains the standard stepper motor accuracy while offering improved positioning resolution after gear reduction.

The gearbox typically uses hardened steel worm shafts and durable bronze or alloy gears for long service life.

Yes, it is designed for continuous-duty operation when used within rated torque and temperature limits.

Yes, gear ratios can be customized to match specific speed and torque requirements.

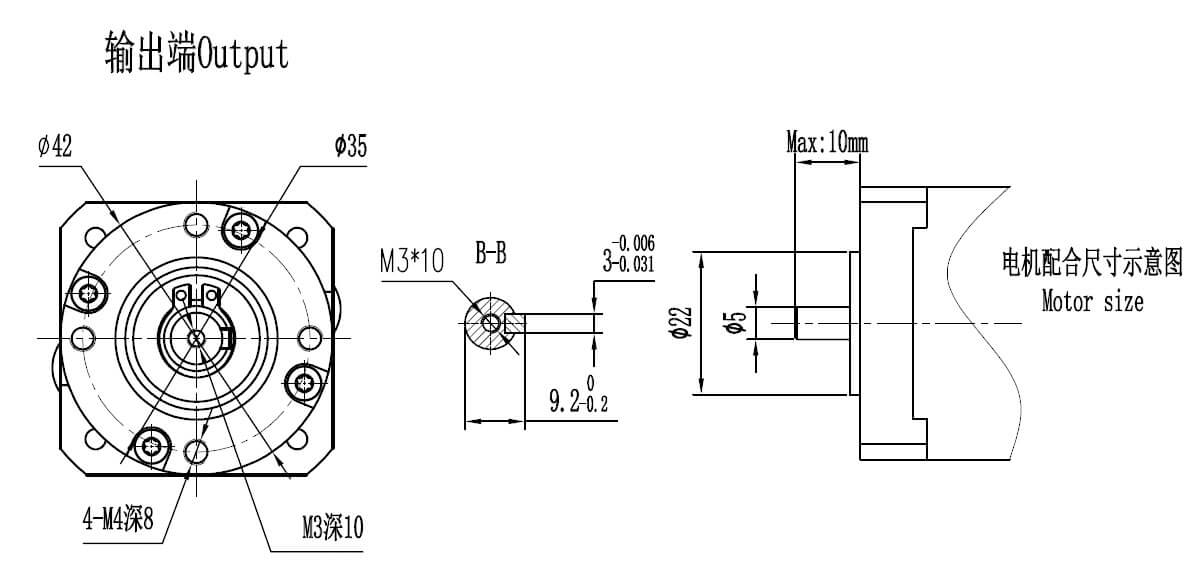

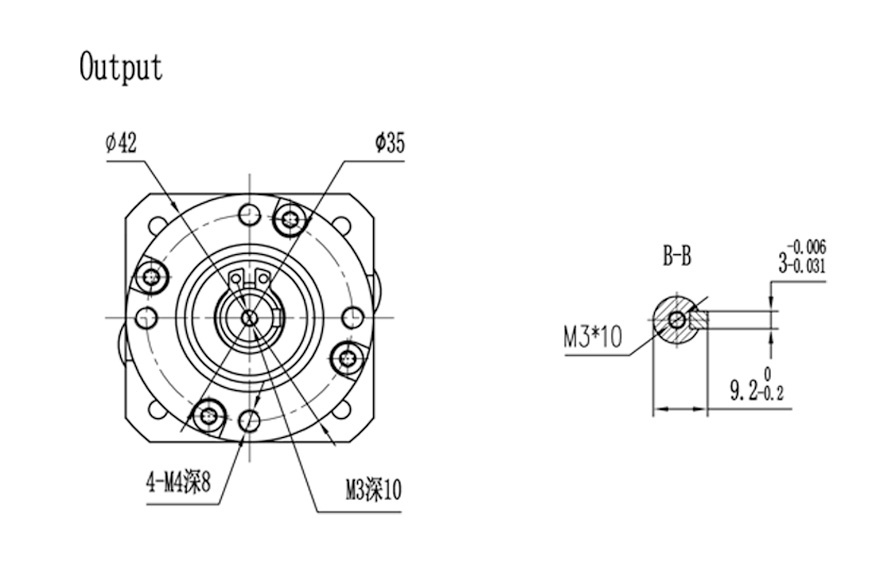

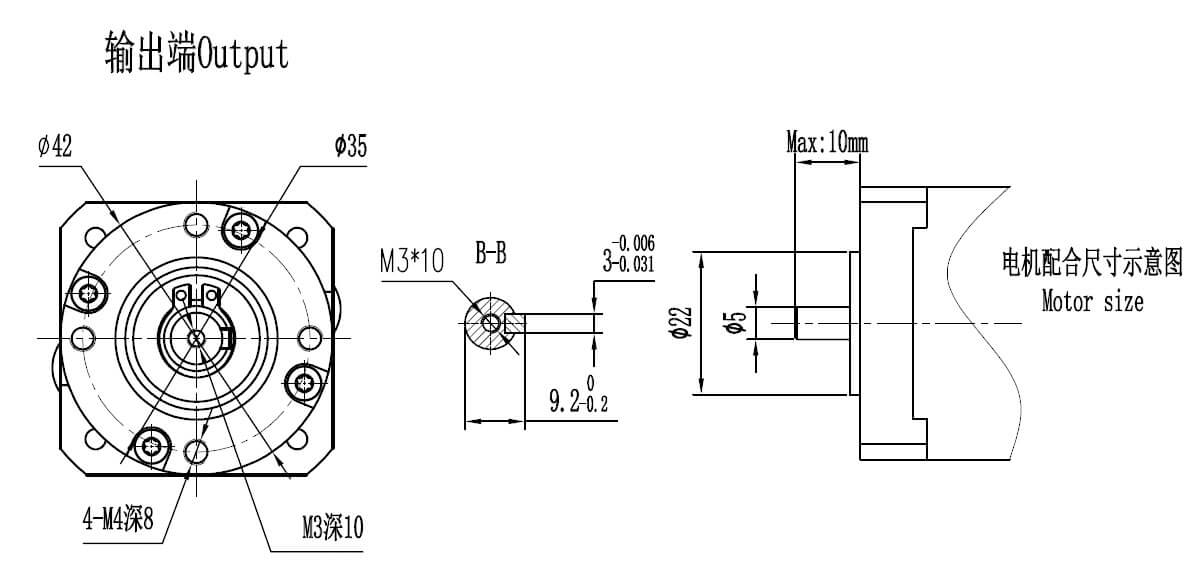

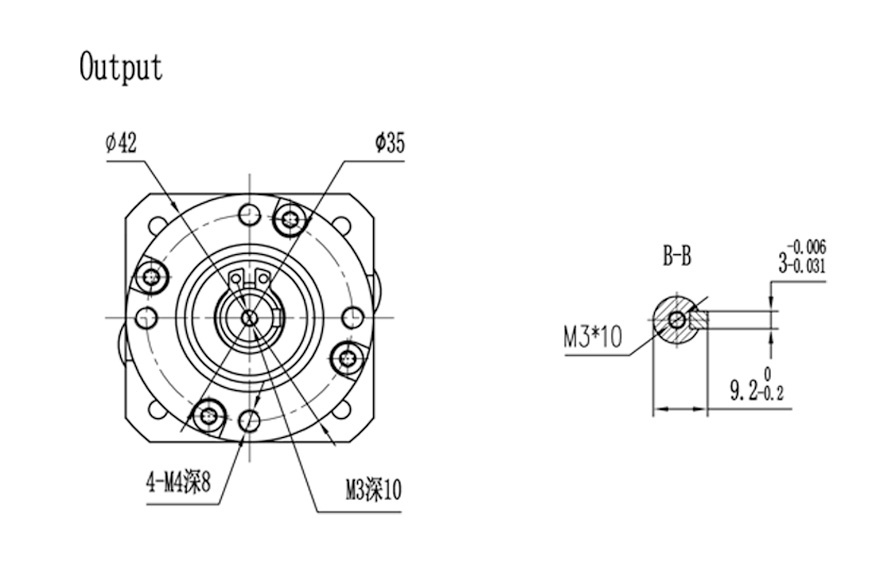

Output shaft diameter, length, and shape can be customized to suit different mechanical designs.

Lean Motor can customize winding parameters to optimize current, torque, and speed for specific applications.

Yes, materials and surface treatments can be customized for high-load, high-temperature, or corrosive environments.

Backlash control and optimization are available to meet high-precision motion control requirements.

Yes, encoders or other feedback devices can be integrated to provide closed-loop control.

Mounting flanges, housings, and mechanical interfaces can be customized for easy integration.

OEM branding, logo printing, and customized packaging are available for brand owners and distributors.

Yes, the factory supports low-MOQ production and prototype development for evaluation and testing.

Lean Motor provides full engineering support, including selection guidance, drawings, performance testing, and after-sales service.

(NEMA 17 Worm Geared Stepper Motor)

A NEMA 17 worm geared stepper motor is widely used in applications requiring high torque, precise positioning, and self-locking capability, such as automation equipment, valve control, medical devices, lifting mechanisms, and robotics.

Worm gearing provides high torque multiplication, compact structure, smooth operation, and a self-locking function that prevents back-driving.

NEMA 17 refers to a 1.7 × 1.7 inch (42 × 42 mm) motor mounting face, making it a standard size for industrial and automation applications.

Yes, worm gear reducers typically offer self-locking, allowing the motor to hold position even when power is off.

Multiple gear ratios are available to meet different torque and speed requirements, depending on the application.

The worm gearbox significantly increases output torque while reducing output speed, ideal for heavy-load and low-speed applications.

Yes, the self-locking feature makes it suitable for vertical movement and load-holding applications.

It maintains the standard stepper motor accuracy while offering improved positioning resolution after gear reduction.

The gearbox typically uses hardened steel worm shafts and durable bronze or alloy gears for long service life.

Yes, it is designed for continuous-duty operation when used within rated torque and temperature limits.

Yes, gear ratios can be customized to match specific speed and torque requirements.

Output shaft diameter, length, and shape can be customized to suit different mechanical designs.

Lean Motor can customize winding parameters to optimize current, torque, and speed for specific applications.

Yes, materials and surface treatments can be customized for high-load, high-temperature, or corrosive environments.

Backlash control and optimization are available to meet high-precision motion control requirements.

Yes, encoders or other feedback devices can be integrated to provide closed-loop control.

Mounting flanges, housings, and mechanical interfaces can be customized for easy integration.

OEM branding, logo printing, and customized packaging are available for brand owners and distributors.

Yes, the factory supports low-MOQ production and prototype development for evaluation and testing.

Lean Motor provides full engineering support, including selection guidance, drawings, performance testing, and after-sales service.