- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-02-12 Origin: Site

India has rapidly emerged as a global hub for Brushless DC (BLDC) motor manufacturing, driven by the accelerating demand for electric vehicles (EVs), industrial automation, HVAC systems, renewable energy equipment, and smart home appliances. As industries transition toward energy-efficient and maintenance-free motor technologies, Indian BLDC motor manufacturers are delivering high-performance, cost-effective, and customized solutions that meet global standards.

In this comprehensive guide, we present the Top 15 BLDC motor manufacturers in India, highlighting each company's profile, core products, and competitive advantages.

|  |  |  |  | A diverse range of products and bespoke services to match the optimal solution for your project.

|

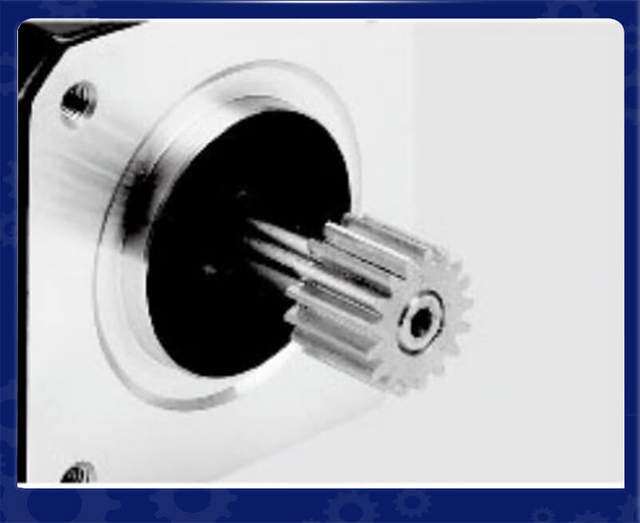

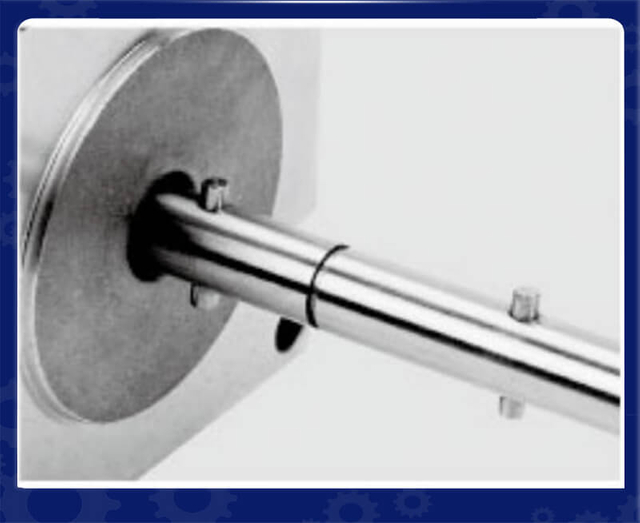

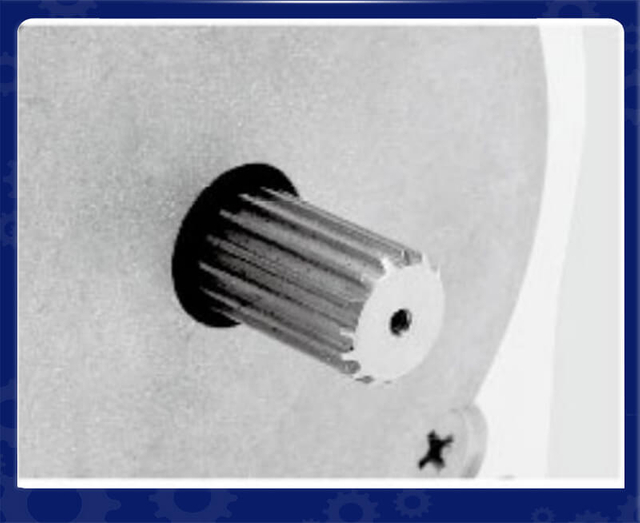

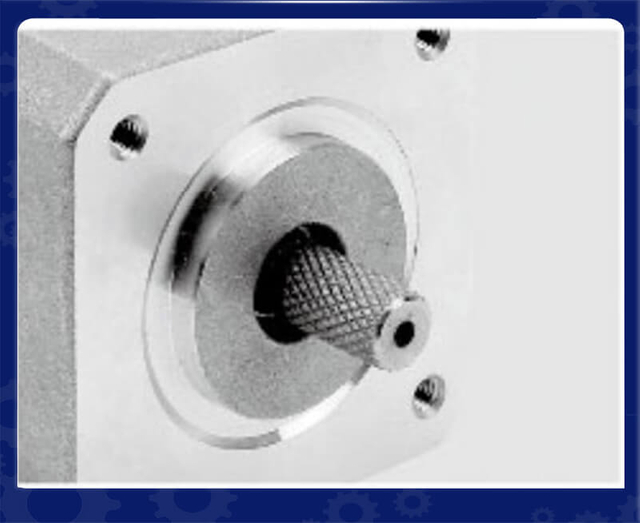

| Pulleys | Gears | Lead Screw | Panel Mount | Flat | |

|  |  |  |  | |

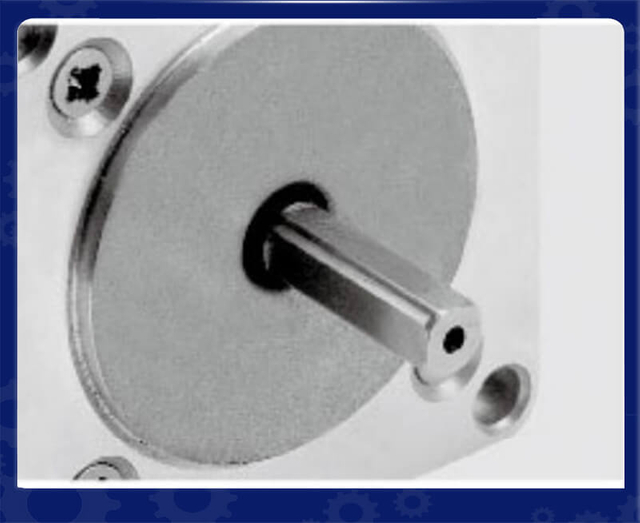

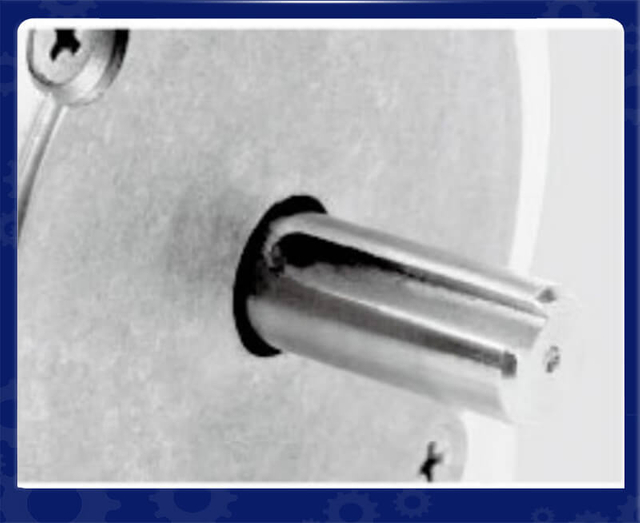

| Key Shaft | Hollow Shaft | Shaft Pin | Panel Mount | Threaded Shaft |

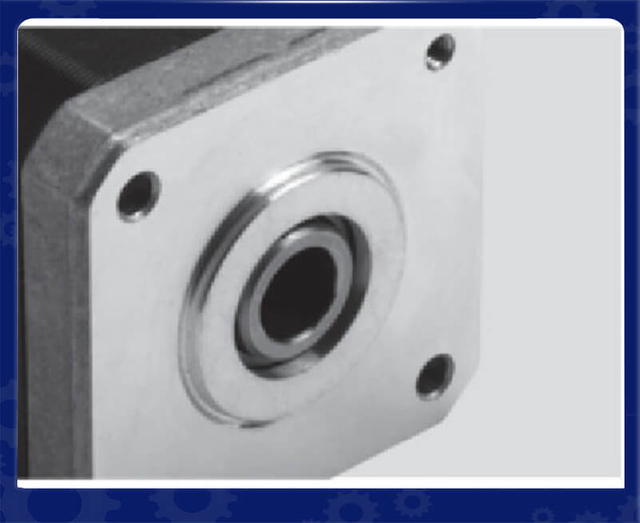

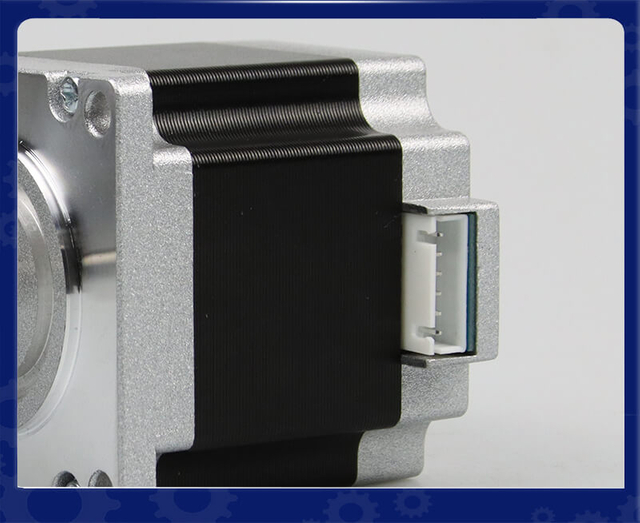

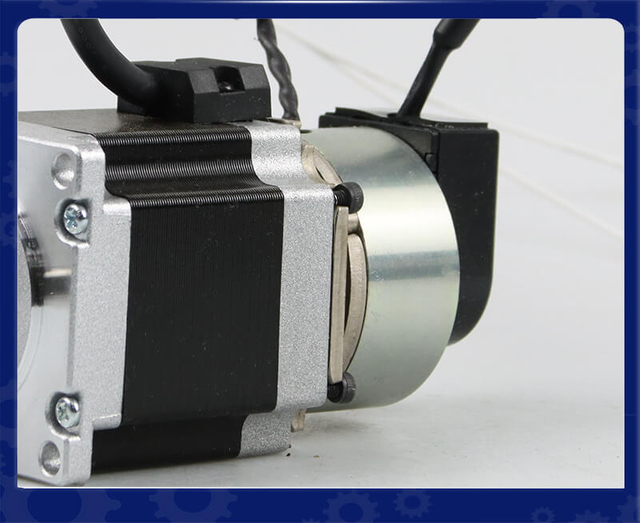

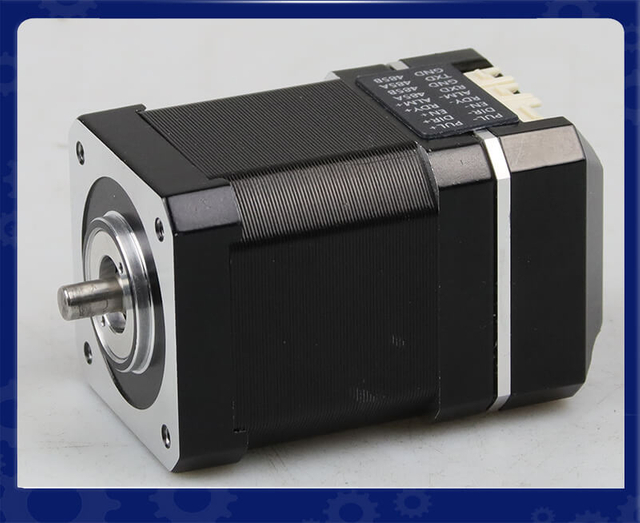

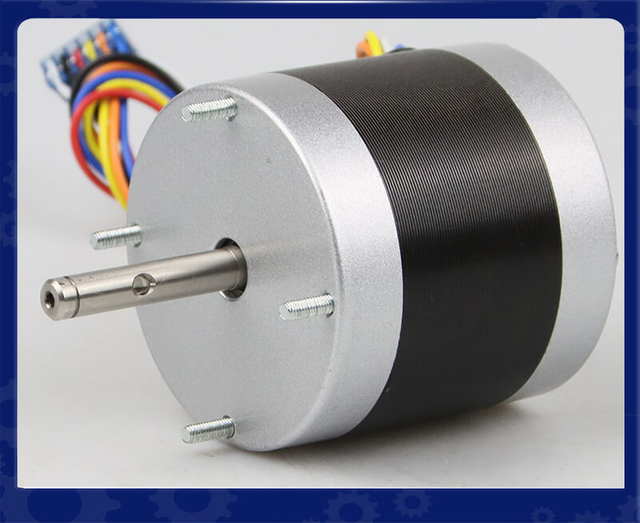

|  |  |  | What differentiates us from other manufacturers is our extensive capability to optimize and tailor our motors to your exact application requirements. We ensure our hybrid stepper motors are finely tuned to deliver the desired performance for your needs—whether that's increasing torque within a specific speed range, reducing noise or vibration, or optimizing for minimal power consumption. Additionally, we can customize the motor's envelope to achieve a native, proper fit within your assembly. We can implement custom modifications to lead wires and connectors, design customized mounting brackets or motor housings for precise fit and alignment, or tailor motor shafts with gears or pulleys to drive your system. Moreover, we can enhance the motor's capabilities with value-add components such as gearboxes, encoders and brakes, integrated drivers, or even custom electronics.

|

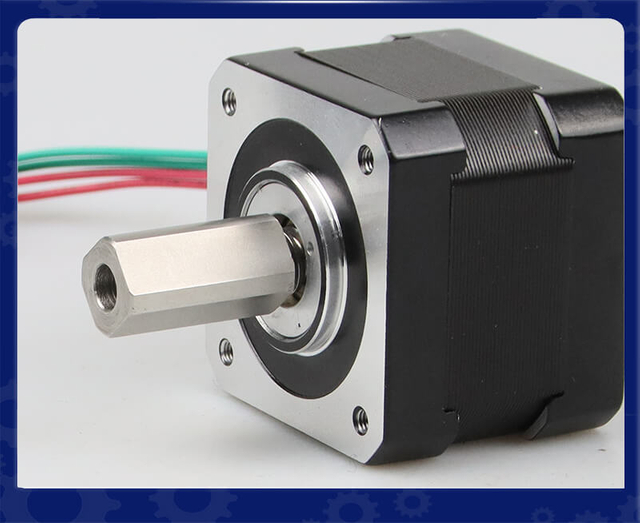

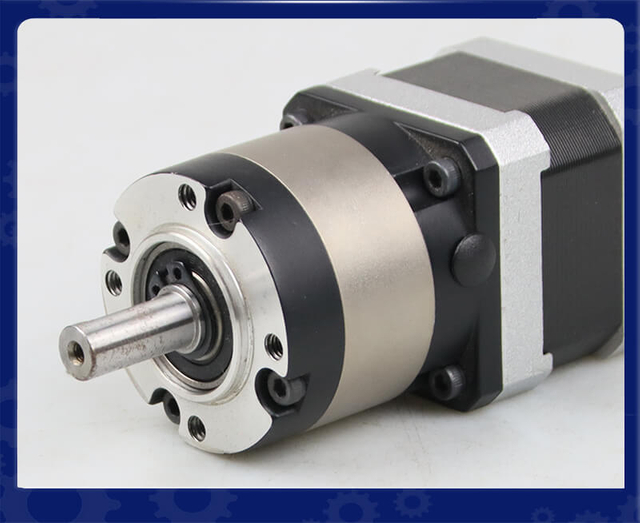

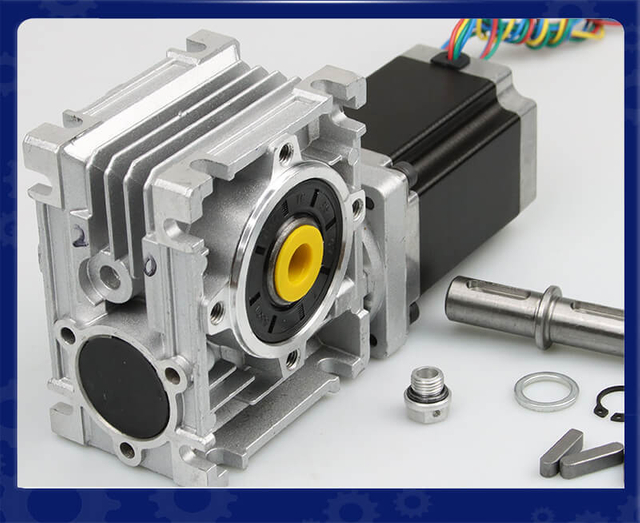

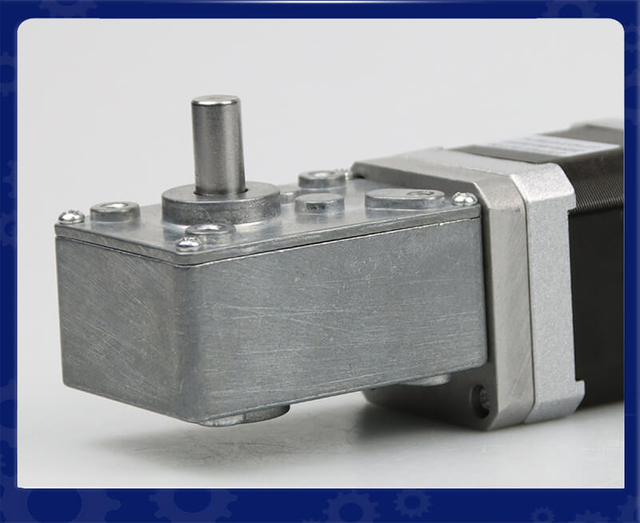

| Wires / Cables | Shaft | Lead Screw | Planetary Gearbox | |

|  |  |  | |

| Worm Gearbox | Worm Gearbox | Encoder | Brake | |

|  |  |  | |

| Integrated Drivers | IP65 Protection | Linear Module | Covers |

The transformation toward Industry 4.0 is redefining how factories operate, how machines communicate, and how production systems optimize themselves in real time. At the core of this intelligent industrial revolution lies one critical component: the Brushless DC (BLDC) motor. As industries shift toward automation, connectivity, energy efficiency, and predictive maintenance, BLDC motors have become a foundational technology enabling smarter, faster, and more reliable manufacturing systems.

Industry 4.0 demands high-precision motion control across robotics, CNC machinery, automated assembly lines, and material handling systems. BLDC motors deliver:

Accurate speed regulation

Consistent torque output

Rapid acceleration and deceleration

Smooth low-speed operation

Because BLDC motors operate using electronic commutation rather than mechanical brushes, they provide superior control when integrated with advanced motor controllers and feedback systems. This precision is essential for collaborative robots (cobots), automated guided vehicles (AGVs), and high-speed packaging systems.

Energy efficiency is no longer optional in modern manufacturing—it is a strategic priority. BLDC motors are inherently more efficient than traditional brushed DC or induction motors due to:

Reduced friction losses (no brushes)

Lower heat generation

Optimized electromagnetic design

High power-to-weight ratio

In Industry 4.0 environments where multiple motors run continuously, even small efficiency gains translate into substantial energy savings. This supports corporate ESG initiatives, carbon reduction targets, and compliance with global efficiency standards.

A defining characteristic of Industry 4.0 is connectivity. BLDC motors integrate seamlessly with:

IoT-enabled motor drives

Smart sensors

PLC systems

Cloud-based monitoring platforms

With built-in controllers and communication protocols such as Modbus, CAN bus, or EtherCAT, BLDC motors enable real-time data transmission on speed, torque, temperature, and vibration. This allows manufacturers to monitor system health and optimize operations through data analytics.

Unplanned downtime is one of the largest costs in industrial production. BLDC motors support predictive maintenance strategies by offering:

Minimal mechanical wear (no brush replacement)

Lower maintenance frequency

Sensor-based diagnostics

Real-time performance tracking

Because they lack brushes, BLDC motors eliminate one of the most failure-prone components found in traditional motors. Combined with smart monitoring, this significantly improves system reliability and uptime.

Industry 4.0 emphasizes flexible, modular manufacturing units that can be quickly reconfigured. BLDC motors offer:

Compact construction

High torque density

Lightweight design

Easy integration into robotic arms and compact machinery

Their space-saving architecture makes them ideal for collaborative robotics, automated inspection systems, and portable industrial equipment.

Modern factories increasingly rely on robotics and automated guided vehicles. BLDC motors provide:

High starting torque

Efficient battery operation

Quiet performance

Extended operational lifespan

For mobile automation platforms powered by batteries, energy efficiency and torque output are critical. BLDC motors excel in both, making them a preferred solution for warehouse automation and smart logistics systems.

Safety is a key pillar of Industry 4.0. BLDC motors contribute to safer environments through:

Precise speed control

Low electromagnetic interference

Reduced overheating

Stable load handling

Accurate electronic commutation reduces mechanical sparking and overheating risks, making BLDC motors suitable for sensitive environments such as pharmaceutical manufacturing and electronics assembly.

Industry 4.0 requires scalable motor solutions that can adapt to different production levels. BLDC motors are used in:

CNC machines

Industrial pumps and compressors

Textile machinery

Packaging equipment

Semiconductor manufacturing

Food processing automation

Their adaptability ensures consistent performance across diverse industries while maintaining efficiency and reliability.

Smart factories prioritize improved working conditions. BLDC motors operate with:

Low acoustic noise

Minimal vibration

Smooth torque delivery

Reduced noise levels are particularly valuable in high-precision manufacturing and collaborative human-robot environments.

Industry 4.0 is built on digital transformation. BLDC motors act as intelligent actuators within cyber-physical systems. When integrated with AI-driven analytics, they enable:

Adaptive speed optimization

Load-based energy adjustment

Real-time process correction

Remote performance diagnostics

This transforms motors from simple mechanical devices into data-generating, intelligent components of a connected ecosystem.

The shift toward automation, electrification, and digitalization requires motor technologies that are efficient, intelligent, and reliable. BLDC motors meet these requirements by combining:

Electronic commutation

High efficiency

Low maintenance

Smart control compatibility

Long service life

As Industry 4.0 continues to evolve, the demand for advanced motion systems will accelerate. BLDC motors are not merely components—they are strategic enablers of intelligent manufacturing.

In the era of Industry 4.0, where connectivity, automation, and sustainability drive industrial competitiveness, BLDC motors play a pivotal role. Their precision, efficiency, and seamless integration with smart control systems make them essential for modern factories.

From robotics and EV production lines to automated warehouses and renewable energy systems, BLDC motor technology is powering the next generation of intelligent industry.

Italy has long been recognized for its excellence in electromechanical engineering, precision manufacturing, and industrial automation technologies. When identifying Italy's best BLDC motor manufacturers, we apply a structured and performance-driven evaluation framework. Our assessment focuses on measurable capabilities, technological depth, manufacturing strength, and global competitiveness.

Below is a comprehensive outline of how we evaluate and rank leading Brushless DC (BLDC) motor manufacturers in Italy.

The foundation of a top-tier BLDC motor manufacturer lies in its research and development strength. We assess:

In-house motor design engineering teams

Advanced electromagnetic simulation capabilities

Thermal management optimization expertise

Continuous innovation in motor control algorithms

Patent portfolio and proprietary technologies

Italian manufacturers with strong R&D investments demonstrate the ability to develop high-efficiency BLDC motors, optimize torque density, and create application-specific solutions for industries such as robotics, EVs, HVAC, and industrial automation.

A leading BLDC motor manufacturer must serve multiple sectors with diversified solutions. We evaluate:

Industrial BLDC motors

Automotive and EV propulsion motors

Servo-integrated BLDC systems

Compact motors for medical devices

High-speed motors for precision machinery

Customized OEM motor assemblies

Manufacturers offering broad application coverage indicate scalability and technical versatility.

Italy is known for precision manufacturing. We analyze:

Factory automation levels

CNC machining and winding technologies

Automated stator and rotor assembly lines

Quality control labs and testing facilities

Annual production capacity

Modern production infrastructure ensures consistency, reduced defect rates, and the ability to handle both high-volume and customized motor orders.

Compliance with international standards is essential for global competitiveness. We evaluate certifications such as:

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

IATF 16949 (Automotive Industry Standards)

CE marking compliance

RoHS and REACH compliance

Manufacturers meeting global certification standards demonstrate reliability, traceability, and export readiness.

Performance remains a critical benchmark. We assess:

Energy efficiency ratings

Torque-to-weight ratio

Speed stability under load

Thermal performance under continuous operation

Noise and vibration levels

Top Italian BLDC motor manufacturers consistently deliver high-efficiency motor systems that support energy-saving and sustainability initiatives.

Many industries require specialized motor configurations. We examine:

Custom shaft and housing design flexibility

Integrated controller solutions

Voltage and speed customization

Application-specific torque tuning

Rapid prototyping capabilities

Manufacturers with strong OEM/ODM services provide competitive advantages for industrial automation integrators and equipment manufacturers.

Italy is a major contributor to European automation innovation. We evaluate how manufacturers support:

IoT-enabled motor control systems

CAN bus, Modbus, EtherCAT communication protocols

Real-time monitoring systems

Predictive maintenance compatibility

Smart drive integration

BLDC motors that align with Industry 4.0 standards demonstrate forward-thinking engineering and digital readiness.

Italy is one of Europe's leading exporters of industrial machinery. We assess:

International distribution networks

Key export markets

Global partnerships

After-sales service support abroad

Manufacturers with a strong global footprint reflect competitive product quality and operational reliability.

Modern manufacturing requires environmental accountability. We evaluate:

Energy-efficient motor designs

Eco-friendly production processes

Sustainable sourcing of raw materials

Carbon footprint reduction initiatives

Companies committed to sustainability align with European Green Deal objectives and global ESG expectations.

Market trust is a powerful indicator of quality. We analyze:

Client testimonials

Long-term industrial partnerships

Case studies in automation and EV sectors

Industry awards and certifications

Manufacturers recognized by leading OEMs and automation firms demonstrate proven reliability.

BLDC motor performance heavily depends on component integrity. We evaluate:

Magnet quality (NdFeB sourcing)

Copper winding standards

Bearing quality and lifecycle testing

Supplier diversification strategies

A stable and high-quality supply chain ensures long-term performance consistency.

Industrial clients demand responsive support. We assess:

Engineering consultation services

Technical documentation depth

Warranty policies

Spare parts availability

Field support capabilities

Manufacturers with robust support systems strengthen long-term customer partnerships.

By combining these criteria, we create a multi-dimensional assessment that measures both technical performance and strategic positioning. Rather than focusing solely on production volume, we prioritize:

Engineering innovation

Customization strength

Efficiency optimization

Smart manufacturing integration

Global competitiveness

This ensures that only manufacturers delivering consistent performance, technological advancement, and scalable production are recognized among Italy's best BLDC motor producers.

Evaluating Italy's best BLDC motor manufacturers requires a structured approach grounded in engineering excellence, manufacturing capability, and digital innovation. By analyzing R&D depth, production quality, Industry 4.0 readiness, and global presence, we identify manufacturers capable of delivering high-performance Brushless DC motor solutions across automotive, industrial, medical, and renewable energy sectors.

This comprehensive evaluation ensures that the selected manufacturers represent the highest standards of Italian precision engineering and global industrial competitiveness.

LeanMotor is a global leading BLDC motor manufacturer with a strong presence in electrification and automation. With decades of expertise,LeanMotor provides advanced BLDC and synchronous motor solutions for industrial and commercial applications.

High-efficiency BLDC motors

Industrial automation drives

Servo and synchronous motors

EV charging and motor systems

Global R&D capabilities

Premium energy-efficient motor technology

Strong service and distribution network

Compliance with international standards

Jkongmotor is a pioneering BLDC motor manufacturer in industrial engineering and motor manufacturing, offering innovative BLDC motor systems integrated with smart control technologies.

Industrial BLDC motors

Integrated motor-drive systems

Smart motion control solutions

EV propulsion systems

Digitalization and IoT-enabled motor systems

High reliability and efficiency

Advanced automation integration

Besfoc is a well-known BLDC motor manufacturer, delivering energy-efficient BLDC motors for CNC,Medical and more applications.

BLDC motors for air conditioners

Energy-efficient pump motors

Industrial drive systems

Strong manufacturing infrastructure

Competitive pricing

Proven track record in energy-saving solutions

Menzel's India operations support specialized industrial motor requirements, including customized BLDC motor solutions for automation and heavy-duty machinery.

Custom BLDC motors

Industrial electric motors

High-voltage motor systems

Strong engineering customization

Reliable industrial-grade quality

Flexible production capability

Shreem Electric is primarily known for power electronics and transformers but also manufactures BLDC-based motor solutions for industrial automation and renewable energy systems.

BLDC motors for industrial drives

Power control equipment

Renewable energy motor systems

Strong power electronics integration

Robust industrial infrastructure

Reliable domestic supply chain

Rotomag specializes in energy-efficient motor technologies and offers BLDC motors for pumps and industrial applications.

BLDC pump motors

Submersible pump motors

Energy-saving drive systems

Focus on agricultural and water management sectors

High efficiency under variable load

Cost-effective rural solutions

A mid-scale BLDC motor manufacturer supplying motors for OEM equipment makers across India, including brushless DC motor solutions.

Custom BLDC motors

AC/DC motors

OEM motor assemblies

Strong OEM collaboration

Flexible batch production

Competitive pricing

Sai Electric develops electric motor solutions for automation and small industrial equipment, including compact BLDC configurations.

Compact BLDC motors

Industrial drive motors

Customized motor assemblies

Fast prototyping

Niche industrial expertise

Adaptable product design

SPM Motors & Drives manufactures industrial motors and motion systems, offering BLDC motors for automation and EV subsystems.

BLDC motors

Servo motors

Industrial drive units

Integrated motor-drive solutions

Strong industrial automation focus

Efficient torque control systems

A regional BLDC motor manufacturer producing customized motor solutions, including brushless DC motors for small industrial and appliance applications.

BLDC motors

Pump motors

Custom-wound electric motors

Flexible customization

Competitive local pricing

Quick turnaround production

Power Build manufactures electric motors and VFD systems, offering BLDC motor systems for industrial and energy-saving applications.

BLDC motors

Variable frequency drives

Energy-efficient industrial motors

Strong drive integration

Reliable industrial performance

Energy optimization expertise

Sky Electric Works focuses on small and mid-sized motor production, including BLDC motors for agricultural and appliance sectors.

BLDC agricultural motors

Appliance brushless motors

Custom motor assemblies

Rural market specialization

Cost-effective designs

Durable construction

Dynamic Electric manufactures electric motors and motion systems for OEM machinery manufacturers, including brushless DC motor variants.

BLDC motors

Industrial AC/DC motors

Gear motor assemblies

Strong OEM relationships

Custom engineering support

Stable domestic production capacity

Surya Electricals produces energy-efficient motor systems and has expanded into BLDC technology for pumps and HVAC systems.

BLDC pump motors

HVAC motor systems

Energy-efficient electric motors

Focus on sustainability

Adaptable motor configurations

Competitive domestic pricing

Fine Automation Robotics provides automation components and motion systems, including high-precision BLDC motors for robotics and CNC machines.

Precision BLDC motors

Servo-integrated systems

Robotic motion components

Strong robotics integration

High precision torque control

Industry 4.0 compatibility

India has rapidly positioned itself as a global leader in BLDC motor manufacturing, driven by a powerful combination of engineering talent, cost-efficient production, strong domestic demand, and expanding export capabilities. As industries worldwide transition toward energy-efficient and digitally integrated systems, Indian manufacturers have scaled innovation, customization, and production excellence to meet global standards.

Below is a comprehensive analysis of the factors that make India a dominant force in the Brushless DC (BLDC) motor industry.

India possesses one of the world's largest pools of electrical and mechanical engineers. This deep technical workforce enables:

Advanced electromagnetic motor design

Thermal optimization for high-efficiency motors

Embedded controller development

Integration with IoT and Industry 4.0 systems

Indian engineers are increasingly contributing to global R&D centers, allowing local manufacturers to design high-performance BLDC motors that compete with European and East Asian brands.

India's manufacturing ecosystem offers significant cost advantages without compromising quality. Key strengths include:

Competitive labor costs

Growing automation in motor production lines

Efficient stator winding and rotor assembly processes

Economical sourcing of copper, laminations, and electronic components

This balance of affordability and quality makes India a preferred sourcing destination for OEMs worldwide seeking cost-effective BLDC motor solutions.

India's aggressive push toward electric mobility has accelerated domestic BLDC motor production. Government initiatives such as FAME (Faster Adoption and Manufacturing of Hybrid and Electric Vehicles) have stimulated demand for:

EV traction BLDC motors

E-bike and e-rickshaw motors

Electric scooter propulsion systems

This fast-growing EV ecosystem has strengthened India's capabilities in high-torque, high-efficiency motor design and large-scale manufacturing.

India is a global production hub for energy-efficient consumer appliances. The widespread adoption of BLDC ceiling fans, air conditioners, and washing machines has fueled:

Mass-scale BLDC motor production

Advanced energy-saving designs

Smart controller integration

Indian brands have become leaders in producing affordable, energy-efficient motors that meet strict regulatory efficiency norms.

Policy support plays a major role in India's leadership. Government initiatives include:

Production Linked Incentive (PLI) schemes

“Make in India” manufacturing programs

Renewable energy incentives

Energy efficiency mandates

These policies encourage domestic manufacturing while attracting foreign investment into the electric motor and electronics sector.

Indian manufacturers are increasingly adopting smart manufacturing technologies, including:

Automated winding machines

Robotics-assisted assembly lines

Digital quality inspection systems

IoT-based production monitoring

BLDC motors manufactured in India are now compatible with advanced communication protocols such as CAN bus and Modbus, making them suitable for global automation systems.

A major strength of Indian BLDC motor manufacturers lies in customization. Companies offer:

Tailored shaft designs

Integrated motor-controller systems

Application-specific torque tuning

Voltage and speed customization

This flexibility allows Indian suppliers to serve diverse industries such as textile machinery, HVAC systems, robotics, solar pumps, and industrial automation.

India's expanding renewable energy sector has created strong demand for BLDC solar pump motors and energy-efficient drive systems. These motors offer:

Low power consumption

Compatibility with solar inverters

High efficiency under variable load

Indian manufacturers have developed durable BLDC pump motors designed for rural and agricultural applications, strengthening their global competitiveness.

India's large population and industrial base create sustained internal demand for:

Household appliance motors

Industrial automation motors

Agricultural pump motors

HVAC systems

This large domestic consumption enables economies of scale, reducing production costs and enhancing export competitiveness.

Indian BLDC motor manufacturers are expanding into markets across:

Southeast Asia

Africa

Europe

Middle East

North America

Improved quality control, international certifications (ISO, CE, RoHS), and strong supply chain management have increased global trust in Indian motor products.

India has steadily localized the supply chain for:

Permanent magnets

Copper windings

Motor laminations

Embedded electronics

Reduced reliance on imports improves production stability and ensures faster lead times for international buyers.

Indian manufacturers are increasingly focusing on:

High torque-to-weight ratio designs

Low-noise and low-vibration motors

Integrated smart motor controllers

AI-enabled performance optimization

This shift positions India not only as a cost-effective producer but also as a technology-driven manufacturing hub.

India's global leadership in BLDC motor manufacturing is built on a strategic combination of:

Engineering excellence

Scalable production capacity

Government-backed industrial growth

Strong EV and renewable energy expansion

Competitive pricing with improving quality standards

From small appliance motors to high-performance EV propulsion systems, India now delivers solutions that meet international efficiency, durability, and smart integration requirements.

India's rise as a global leader in BLDC motor manufacturing is the result of sustained investment in technology, manufacturing infrastructure, and policy-driven industrial growth. With a strong domestic market, expanding export presence, and increasing digital integration, India continues to strengthen its position in the global electric motor ecosystem.

As industries worldwide prioritize energy efficiency, automation, and electrification, Indian BLDC motor manufacturers are well positioned to remain at the forefront of innovation and scalable production.

The Indian BLDC motor industry represents a powerful blend of technological advancement, scalable manufacturing, and cost competitiveness. The companies listed above stand at the forefront of innovation, delivering cutting-edge motor solutions tailored for modern applications. Whether the requirement is high-torque industrial motors, energy-efficient residential systems, or customized EV propulsion solutions, these manufacturers offer reliable, performance-driven options.

For businesses seeking trusted BLDC motor manufacturers in India, this list provides a strong foundation for selecting partners committed to quality, efficiency, and long-term performance.

Leading BLDC motor manufacturers in India offer standard BLDC motor models, geared BLDC motors, integrated BLDC motors, and application-specific solutions for industrial and consumer markets.

A standard BLDC motor from a reputable India BLDC motor manufacturer can match international efficiency and durability standards while offering competitive pricing.

Industries such as home appliances, EVs, automation, HVAC, medical equipment, and robotics widely use BLDC motors.

Yes, many BLDC motor manufacturers in India specialize in EV-grade motors designed for high efficiency and continuous operation.

Common voltage options include 12V, 24V, 36V, 48V, and higher voltages for industrial and EV applications.

Yes, a high-quality standard BLDC motor offers high efficiency, lower heat generation, and reduced maintenance compared to brushed motors.

Yes, BLDC motors are designed to work with electronic controllers for precise speed and torque control.

Many manufacturers provide planetary, spur, or worm geared BLDC motors to increase torque output.

Look for certifications, production capacity, R&D capability, quality testing processes, and export experience.

Yes, many India BLDC motor manufacturers meet CE, RoHS, and other international compliance standards.

Yes, most leading BLDC motor manufacturers in India offer custom BLDC motor solutions tailored to specific torque, speed, and voltage requirements.

Custom BLDC motors may include special windings, shaft modifications, integrated drivers, customized housings, and application-specific mounting designs.

Yes, many manufacturers provide full OEM and ODM support from design to mass production.

MOQ varies depending on customization complexity, but many manufacturers support prototype and low-volume production.

A standard BLDC motor typically has shorter lead times, while custom BLDC motors require additional engineering and validation time.

Yes, established manufacturers have automated production lines capable of scaling to large-volume orders.

Quality control includes performance testing, thermal testing, endurance testing, and strict inspection procedures.

Yes, integrated BLDC motor solutions with built-in controllers are available for compact system design.

Yes, many global buyers choose India BLDC motor manufacturers due to competitive pricing and strong engineering support.

A professional BLDC motor manufacturer in India offers reliable quality, flexible customization, export experience, and cost-efficient production for both standard BLDC motors and custom BLDC motor projects.