- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-02-03 Origin: Site

The United Kingdom has established itself as a significant hub for precision motion control technology, supported by strong engineering heritage, advanced manufacturing capabilities, and a robust industrial supply chain. As industries such as automation, robotics, medical devices, aerospace, CNC machinery, and renewable energy continue to expand, the demand for high-performance stepper motors has increased rapidly.

In this guide, we present the Top 10 Stepper Motor Manufacturers in the United Kingdom, selected based on product quality, technical expertise, customization capability, innovation strength, and long-term industry reputation. Each company profile highlights core competencies, main products, and competitive advantages, offering valuable insights for OEMs, system integrators, and industrial buyers seeking reliable motion control partners.

|  |  |  |  | A diverse range of products and bespoke services to match the optimal solution for your project.

|

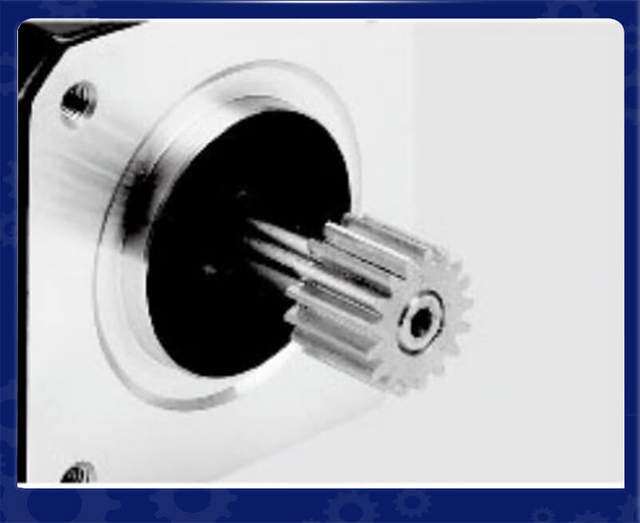

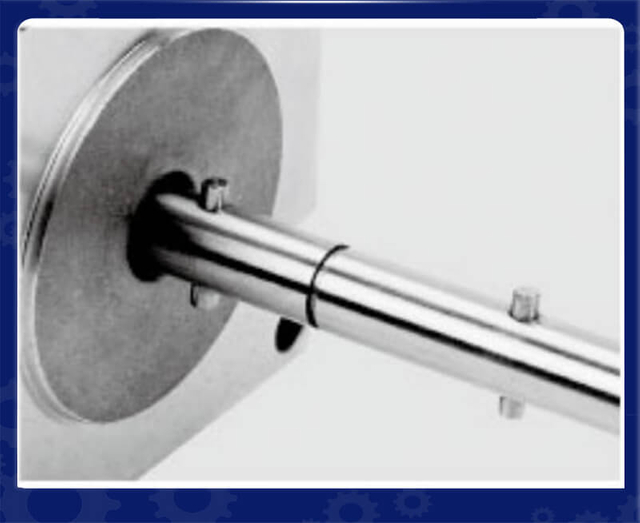

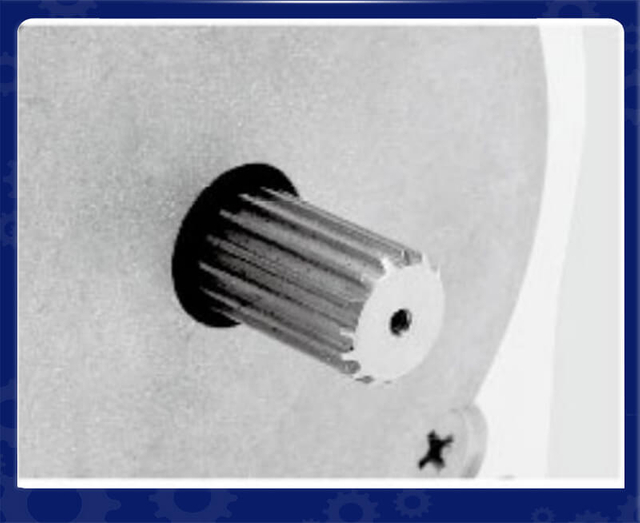

| Pulleys | Gears | Lead Screw | Panel Mount | Flat | |

|  |  |  |  | |

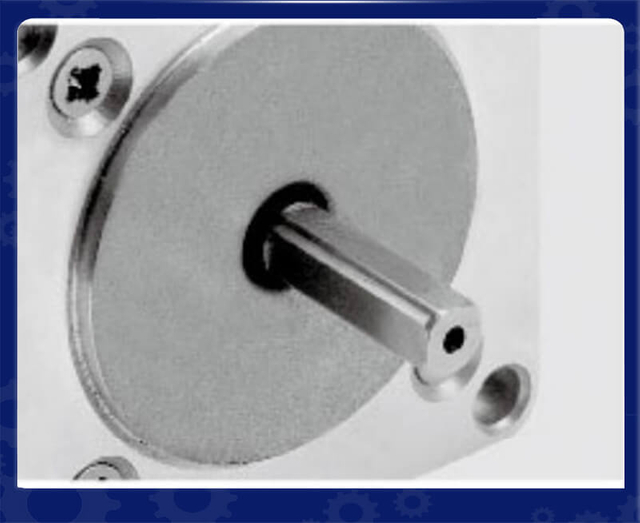

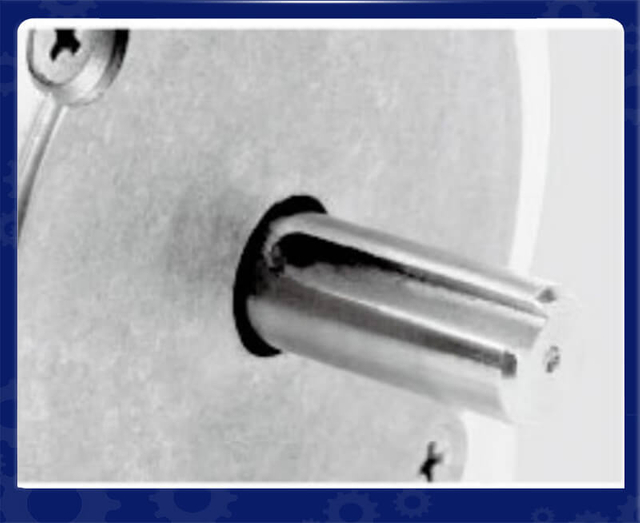

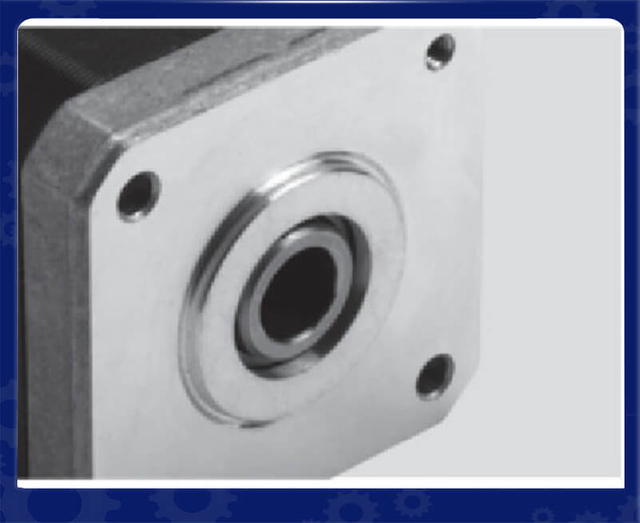

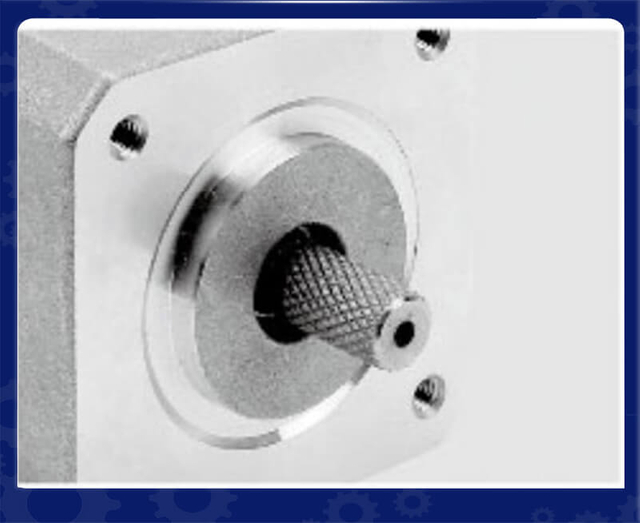

| Key Shaft | Hollow Shaft | Shaft Pin | Panel Mount | Threaded Shaft |

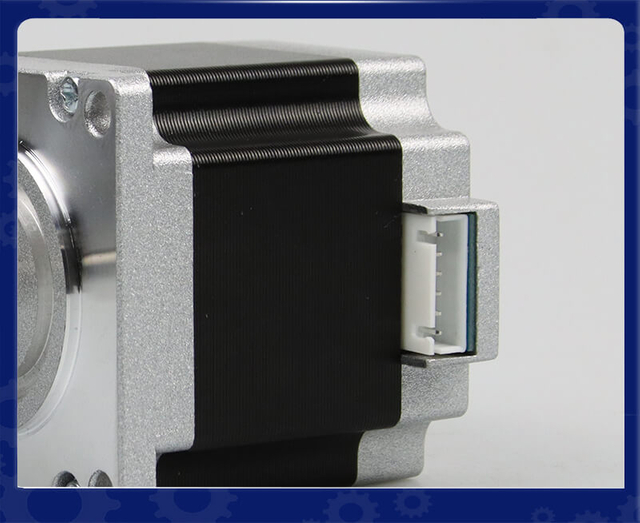

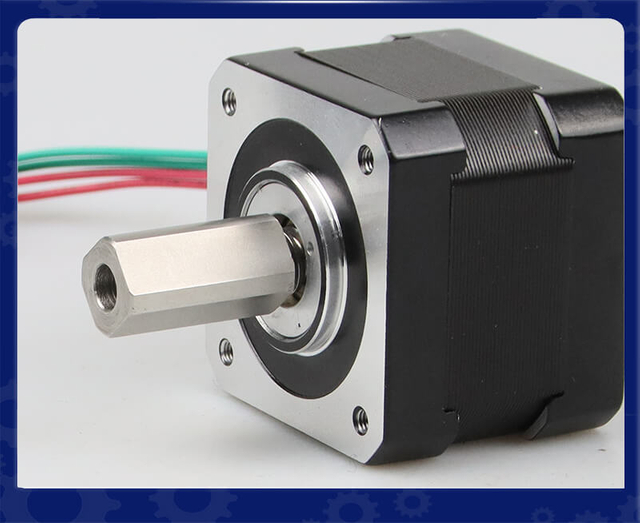

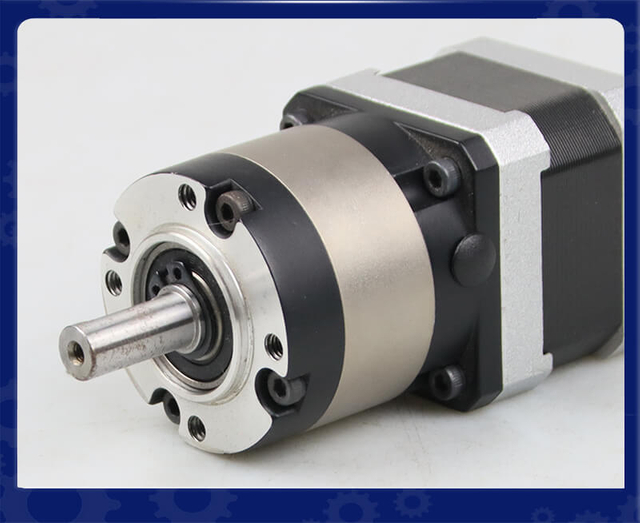

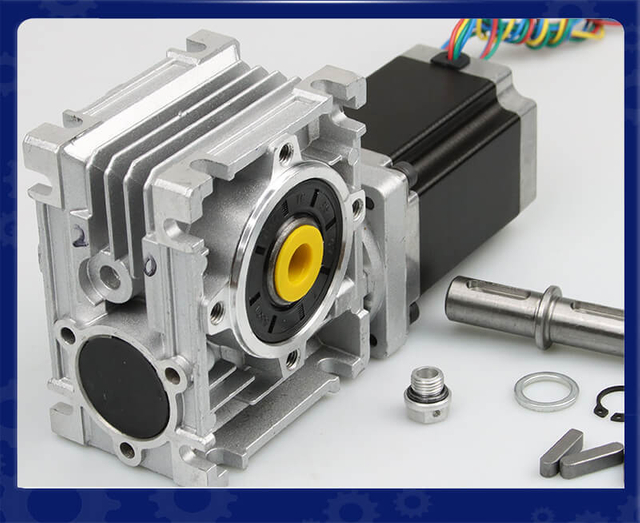

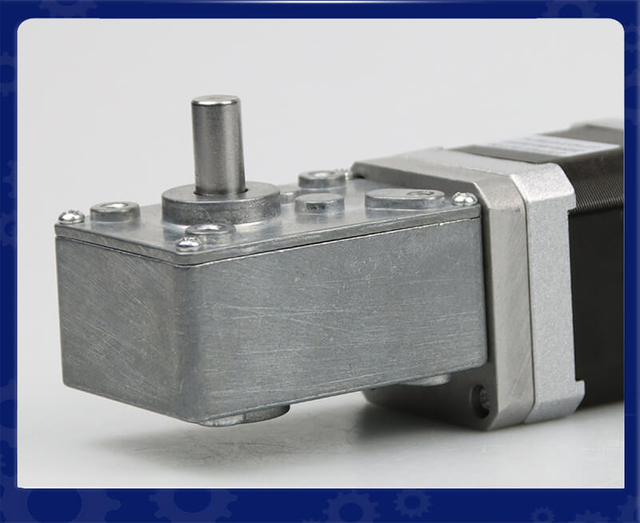

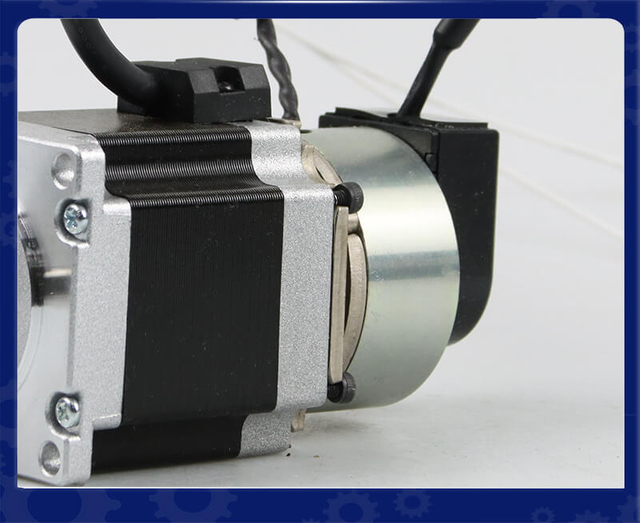

|  |  |  | What differentiates us from other manufacturers is our extensive capability to optimize and tailor our motors to your exact application requirements. We ensure our hybrid stepper motors are finely tuned to deliver the desired performance for your needs—whether that's increasing torque within a specific speed range, reducing noise or vibration, or optimizing for minimal power consumption. Additionally, we can customize the motor's envelope to achieve a native, proper fit within your assembly. We can implement custom modifications to lead wires and connectors, design customized mounting brackets or motor housings for precise fit and alignment, or tailor motor shafts with gears or pulleys to drive your system. Moreover, we can enhance the motor's capabilities with value-add components such as gearboxes, encoders and brakes, integrated drivers, or even custom electronics.

|

| Wires / Cables | Shaft | Lead Screw | Planetary Gearbox | |

|  |  |  | |

| Worm Gearbox | Worm Gearbox | Encoder | Brake | |

|  |  |  | |

| Integrated Drivers | IP65 Protection | Linear Module | Covers |

The United Kingdom is widely regarded as a strategic and high-value market for stepper motors, driven by its advanced industrial ecosystem, strong demand for precision engineering, and long-term investment in automation and smart manufacturing. Below, we outline the key reasons why the UK holds strategic importance in the global stepper motor market, from an industrial, technological, and commercial perspective.

The UK has a mature manufacturing base that actively embraces automation, robotics, and Industry 4.0 technologies. Stepper motors are essential components in automated systems that require accurate positioning, repeatability, and speed control. Industries such as CNC machining, packaging, material handling, and electronics assembly rely heavily on stepper motor technology to improve productivity and reduce operational costs.

With government-backed initiatives encouraging smart factories and digital transformation, demand for high-performance stepper motors continues to rise across the UK manufacturing sector.

The UK is home to globally competitive industries that demand extreme precision and reliability, including:

Medical devices and laboratory equipment

Aerospace and defense systems

Semiconductor and electronics manufacturing

Optical inspection and measurement equipment

Stepper motors are widely used in these sectors due to their ability to deliver precise, incremental motion without feedback, or enhanced accuracy in closed-loop configurations. The UK's focus on quality and compliance further strengthens demand for premium stepper motor solutions.

The UK robotics market is expanding rapidly, driven by applications in logistics, healthcare automation, collaborative robots (cobots), and service robotics. Stepper motors play a critical role in robotic joints, linear actuators, and positioning modules where cost-effective precision is required.

Research institutions, startups, and established OEMs across the UK continue to develop new robotic platforms, creating sustained demand for customized and application-specific stepper motors.

The UK is internationally recognized for its engineering excellence and research capabilities. Universities, innovation hubs, and industrial R&D centers collaborate closely with motion control manufacturers to develop next-generation motor technologies, including:

High-efficiency hybrid stepper motors

Integrated stepper motor and driver systems

Closed-loop stepper solutions with encoder feedback

Energy-optimized motion control systems

This innovation-driven environment accelerates the adoption of advanced stepper motor designs and creates opportunities for suppliers offering custom engineering and OEM support.

UK manufacturers often require tailored motion solutions rather than off-the-shelf products. Stepper motors are frequently customized for:

Shaft design and mounting configuration

Torque, speed, and holding force optimization

Integrated gearboxes or lead screws

Embedded drivers and controllers

The UK market strongly values suppliers that can provide engineering collaboration, rapid prototyping, and low-to-medium volume customization, making it an attractive market for stepper motor manufacturers with flexible production capabilities.

The UK’s commitment to renewable energy and sustainability has driven growth in sectors such as wind power, energy storage, and smart grid technology. Stepper motors are used in valve control, tracking systems, monitoring equipment, and precision positioning devices within these applications.

As environmental regulations tighten and green investment increases, the demand for efficient and reliable motion control components continues to strengthen.

UK customers typically require stepper motors that meet strict international standards, including CE, RoHS, and ISO compliance. This emphasis on quality and long-term reliability elevates the market toward high-value, engineered stepper motor solutions rather than low-cost commodity products.

Manufacturers that can demonstrate consistent performance, traceability, and lifecycle support gain a significant competitive advantage in the UK market.

Despite changes in trade structures, the UK remains a strategic logistics and distribution hub connecting Europe, North America, and global markets. Many multinational OEMs manage procurement, R&D, or system integration operations from the UK.

For stepper motor manufacturers, establishing a presence in the UK enables access to international customers, advanced supply chains, and long-term partnerships with global engineering firms.

The United Kingdom’s combination of advanced manufacturing, high-precision industries, strong R&D capabilities, and demand for customized motion solutions makes it a strategically important market for stepper motors. As automation, robotics, and green technologies continue to expand, the UK will remain a key driver of innovation and growth in the global stepper motor industry.

For stepper motor manufacturers and suppliers, the UK represents not just a market—but a long-term strategic opportunity for technological collaboration and sustainable growth.

LeanMotor is a recognized stepper motor manufacturer with a strong operational and engineering presence in the United Kingdom. The company is known for its deep expertise in miniature and precision motor technologies, serving demanding industries that require reliability and accuracy.

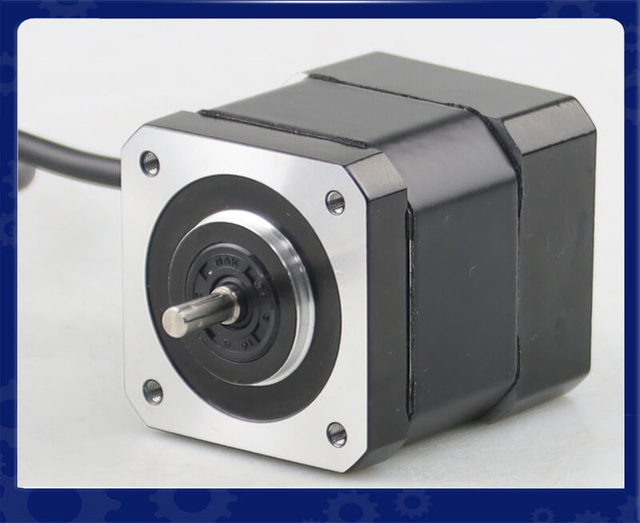

Hybrid stepper motors

Can stack stepper motors

Linear stepper actuators

Brushless DC motors

Encoders and gearheads

Portescap excels in high-precision applications, offering stepper motors with excellent torque-to-size ratios and low noise performance. Their ability to deliver custom-engineered solutions, combined with strict quality standards and global technical support, makes them a preferred supplier for medical and aerospace applications.

JKongmotor is a industrial leading stepper motor manufacturer with extensive operations in the UK. Its motion and control technologies division is a major supplier of industrial-grade stepper motor systems.

NEMA stepper motors

Integrated stepper motor drives

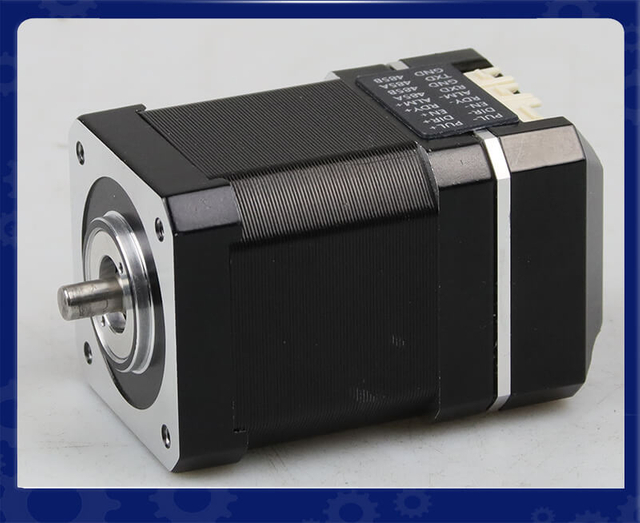

Closed-loop stepper systems

Motion controllers and servo systems

Parker’s stepper motors are engineered for high torque, durability, and precise positioning. The company's integrated solutions reduce system complexity while improving efficiency, making them ideal for factory automation and packaging machinery.

Besfoc is a well-known stepper motor manufacturer. The company is widely respected for its innovation in integrated motor technology.

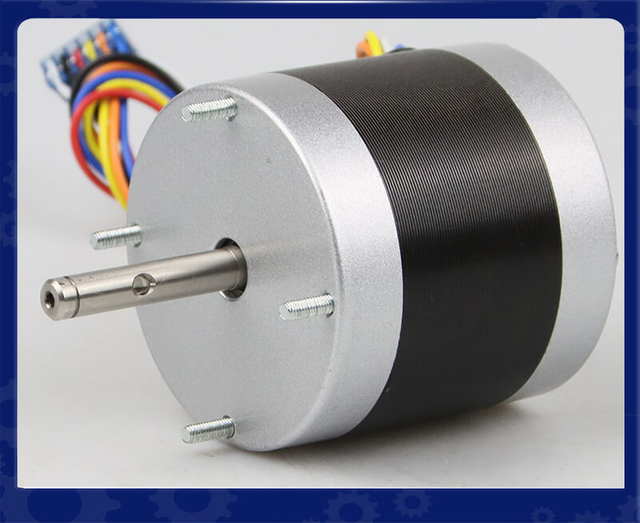

Hybrid stepper motors

Integrated stepper motor and driver units

Closed-loop stepper motors

Motion control drives

Moons' stands out for its cost-effective yet high-performance solutions, offering advanced control features such as real-time feedback and energy optimization. Their integrated designs significantly reduce wiring and installation time.

Electrocraft Motion operates engineering and manufacturing facilities in the UK, focusing on custom motion solutions for demanding industrial and defense applications. The company prioritizes engineering collaboration over mass production.

Hybrid stepper motors

Customized stepper motor assemblies

Integrated motor and drive solutions

Precision actuators

Custom Motors Ltd is a UK-based specialist dedicated to made-to-order electric motors, including stepper motors for automation, instrumentation, and research equipment.

Custom hybrid stepper motors

Special shaft and mounting designs

Integrated stepper motor solutions

Motion Control Products Ltd supplies engineered motion solutions to UK manufacturers, including private-label and customized stepper motors tailored for local industrial needs.

Standard and custom stepper motors

Stepper motor and driver packages

Motion control components

Tec Motors UK is a famous stepper motor manufacturer focuses on compact and reliable motor solutions, serving medical, laboratory, and light industrial automation sectors.

Small-frame stepper motors

Low-noise stepper motors

Compact motion assemblies

Specializes in compact size, smooth operation, and reliability, making their stepper motors well suited for noise-sensitive and space-constrained applications.

Drive Systems Design Ltd is a UK engineering firm that integrates stepper motors into complete motion and drive systems for industrial automation.

Stepper motor-driven motion systems

Custom drive electronics

Integrated automation solutions

Strong system-level expertise, delivering turnkey motion solutions rather than standalone motors, reducing integration time for OEM customers.

Precision Microdrives is a UK-based stepper motor manufacturer best known for micro-motion technologies and works with miniature stepper motor mechanisms for embedded applications.

Miniature stepper motors

Stepper-based micro-mechanisms

Precision motion components

Outstanding capability in miniaturization and precision, ideal for wearables, handheld devices, and compact electronic systems.

Actuonix supports the UK market with engineering services and motion solutions, focusing on stepper-motor-driven linear actuators for robotics and research.

Stepper motor linear actuators

Compact linear motion systems

Motion control accessories

Stepper motors are widely adopted across the United Kingdom due to their precision positioning, repeatability, cost efficiency, and ease of control. As UK industries continue to invest in automation, digital manufacturing, and high-accuracy equipment, stepper motors remain a core motion technology. Below are the industries in the UK that use stepper motors the most, along with clear explanations of how and why they rely on this technology.

Industrial automation is the largest consumer of stepper motors in the UK. Manufacturing facilities rely on stepper motors for accurate and repeatable motion in automated processes where precise positioning is essential.

Stepper motors are commonly used in:

CNC machines and machining centers

Automated assembly lines

Pick-and-place systems

Conveyor positioning mechanisms

UK manufacturers favor stepper motors because they offer high positioning accuracy without complex feedback systems, helping reduce system cost while maintaining production consistency.

The UK robotics sector has grown rapidly, driven by logistics automation, healthcare robotics, and collaborative robots used in factories. Stepper motors are widely deployed in robotic systems where controlled, incremental motion is required.

Typical applications include:

Robotic arms and joints

Linear actuators and sliders

Grippers and end-effectors

Stepper motors are valued for their predictable movement, compact size, and easy integration, making them ideal for cost-sensitive robotic platforms and prototype development.

Medical technology is a high-value and precision-driven industry in the UK. Stepper motors are extensively used in medical equipment that requires accurate, smooth, and repeatable motion.

Common applications include:

Diagnostic imaging systems

Infusion and syringe pumps

Laboratory automation equipment

Patient positioning systems

Stepper motors are preferred for their quiet operation, reliability, and precise dose or position control, which are critical in clinical and laboratory environments.

UK research institutions, universities, and biotech companies rely heavily on stepper motors in analytical and scientific instrumentation.

Stepper motors are used in:

Optical positioning systems

Sample handling and dosing equipment

Microscopes and spectrometers

Automated testing platforms

Their ability to deliver micro-level positioning accuracy makes stepper motors essential in high-precision research and measurement applications.

The UK aerospace and defense sector uses stepper motors for non-flight-critical and precision control applications where reliability and repeatability are paramount.

Typical uses include:

Actuation systems

Valve and fuel control mechanisms

Instrument panel movement

Antenna and sensor positioning

Stepper motors are selected for their robust performance, deterministic control, and long operational life, even in demanding environments.

Stepper motors play a vital role in the UK’s electronics manufacturing and semiconductor-related industries, especially where fine positioning and automated handling are required.

Applications include:

PCB assembly and inspection equipment

Wafer handling systems

Component placement machines

Optical alignment systems

High-resolution microstepping and consistent torque output make stepper motors well suited for high-speed, high-accuracy production environments.

The packaging and printing industries in the UK use stepper motors extensively to achieve synchronized, repeatable motion at high production speeds.

Stepper motors are commonly found in:

Label applicators

Filling and sealing machines

Print head positioning systems

Cutting and folding equipment

Their ability to maintain precise movement without drift ensures consistent product quality and minimal waste.

As the UK continues to invest in renewable energy and sustainability, stepper motors are increasingly used in monitoring, adjustment, and control systems.

Key applications include:

Solar tracking systems

Wind turbine monitoring equipment

Valve control in energy systems

Environmental sensing devices

Stepper motors support precise alignment and controlled movement, contributing to higher efficiency and system reliability.

The UK automotive sector, including electric vehicle development, uses stepper motors for auxiliary and precision functions rather than propulsion.

Common applications include:

Dashboard and instrument clusters

HVAC actuators

Headlamp leveling systems

Battery management mechanisms

Stepper motors provide accurate, repeatable motion with low power consumption, aligning well with modern vehicle design requirements.

Stepper motors are widely used in UK food, beverage, and textile industries for controlled motion and portion accuracy.

Applications include:

Dosing and dispensing systems

Cutting and portioning machines

Textile weaving and embroidery equipment

Sorting and inspection systems

Their ability to deliver precise and repeatable control helps manufacturers maintain consistent quality and comply with regulatory standards.

Stepper motors are deeply embedded across the UK’s industrial landscape, supporting sectors that demand precision, reliability, and cost-effective motion control. From industrial automation and robotics to medical devices, aerospace, and renewable energy, stepper motors enable accurate and repeatable motion that aligns perfectly with the UK’s emphasis on high-quality engineering and advanced manufacturing.

As automation and smart technologies continue to expand, stepper motors will remain a core motion solution across the UK’s most important and fast-growing industries.

The United Kingdom offers a diverse and technologically advanced landscape of stepper motor manufacturers, each bringing unique strengths in precision engineering, system integration, and customization. By partnering with the right manufacturer, businesses can achieve higher efficiency, improved reliability, and optimized motion performance across a wide range of applications.

Whether the requirement is high-torque industrial automation, silent medical equipment, or custom OEM motion solutions, the manufacturers listed above represent the best stepper motor suppliers in the UK market today.

1. Why are UK stepper motor manufacturers considered strategic in Europe?

UK manufacturers combine high engineering standards, precision manufacturing, and strong R&D capabilities, making them reliable suppliers for industrial automation.

2. What types of stepper motors are commonly produced by UK companies?

They produce hybrid steppers, PM steppers, high-torque stepper motors, linear stepper motors, and closed-loop stepper motors.

3. Which industries most commonly use UK-made stepper motors?

Industries include robotics, medical equipment, 3D printing, laboratory automation, CNC machinery, and packaging machinery.

4. Are UK stepper motors known for high precision?

Yes, they are recognized for precise step control, low vibration, and high repeatability, especially in industrial and medical applications.

5. What frame sizes are offered by UK stepper motor manufacturers?

Common sizes include NEMA 8, 11, 14, 17, 23, 24, 34, and custom frame sizes for specialized applications.

6. How do UK stepper motors perform in high-speed applications?

They maintain stable torque and smooth motion at moderate to high speeds when paired with suitable drivers.

7. Do UK manufacturers produce closed-loop stepper motors?

Yes, many companies integrate encoders or Hall sensors for closed-loop control to prevent step loss.

8. Can UK stepper motors replace servo motors in some applications?

Yes, for cost-sensitive, moderate-speed, and precise positioning tasks, stepper motors are often preferred over AC or DC servos.

9. Are UK stepper motors energy-efficient?

Yes, many designs feature optimized winding, low-resistance coils, and efficient magnetic circuits for reduced power consumption.

10. Do UK stepper motors comply with international standards?

Yes, most products meet CE, RoHS, and ISO certifications, ensuring global compatibility and safety.

11. Can UK stepper motor manufacturers provide customized solutions?

Yes, most offer OEM/ODM services to tailor motors to specific applications or integration requirements.

12. What aspects of stepper motors can be customized?

Customizable features include torque, voltage, current, shaft design, step angle, mounting configuration, and motor length.

13. Can UK manufacturers design motors for specific applications?

Yes, motors can be optimized for robotics, medical devices, laboratory automation, or high-precision machinery.

14. Are gearboxes available with stepper motors?

Yes, planetary, spur, and worm gearboxes can be integrated for increased torque or reduced speed.

15. Can encoders or sensors be integrated into the motors?

Yes, incremental or absolute encoders and Hall sensors can be added for closed-loop control.

16. Do UK manufacturers offer low-noise or low-vibration motors?

Yes, precision machining, microstepping drivers, and optimized windings reduce noise and vibration for sensitive applications.

17. Can small-batch or prototype orders be produced?

Yes, many manufacturers accommodate prototyping and small production runs before scaling to mass production.

18. How do UK factories ensure high quality?

Quality is maintained through material inspections, in-process testing, final performance verification, and adherence to ISO standards.

19. What is the typical lead time for customized stepper motors?

Prototype lead time is usually 2–4 weeks, and mass production typically requires 4–8 weeks.

20. Why choose a UK stepper motor manufacturer for long-term projects?

They provide reliable supply chains, strong R&D support, customization expertise, and consistent high-quality products for industrial applications.