- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

LMBLD120

LeanMotor

10 Pcs

LMBLD120 DC brushless driver is suitable for speed regulation of three-phase DC brushless motors with power below 120W, and it can provide external potentiometer speed regulation, external analog voltage speed regulation, and PWM speed regulation of upper computer (PLC, microcontroller, etc.). At the same time the driver has a large torque start, fast start and braking, forward and reverse switching, manual and automatic speed control. It is suitable for DC brushless motors with voltage from 12V to 30V and power below 120W.

Acc/Dec time setting

Built-in RV speed setting

Max output current P-sv setting

External potentiometer speed setting

Restart

External analog signal speed setting

Alarm signal

LMBLD120 DC brushless driver is suitable for speed regulation of three-phase DC brushless motors with power below 120W, and it can provide external potentiometer speed regulation, external analog voltage speed regulation, and PWM speed regulation of upper computer (PLC, microcontroller, etc.). At the same time the driver has a large torque start, fast start and braking, forward and reverse switching, manual and automatic speed control. It is suitable for DC brushless motors with voltage from 12V to 30V and power below 120W.

Acc/Dec time setting

Built-in RV speed setting

Max output current P-sv setting

External potentiometer speed setting

Restart

External analog signal speed setting

Alarm signal

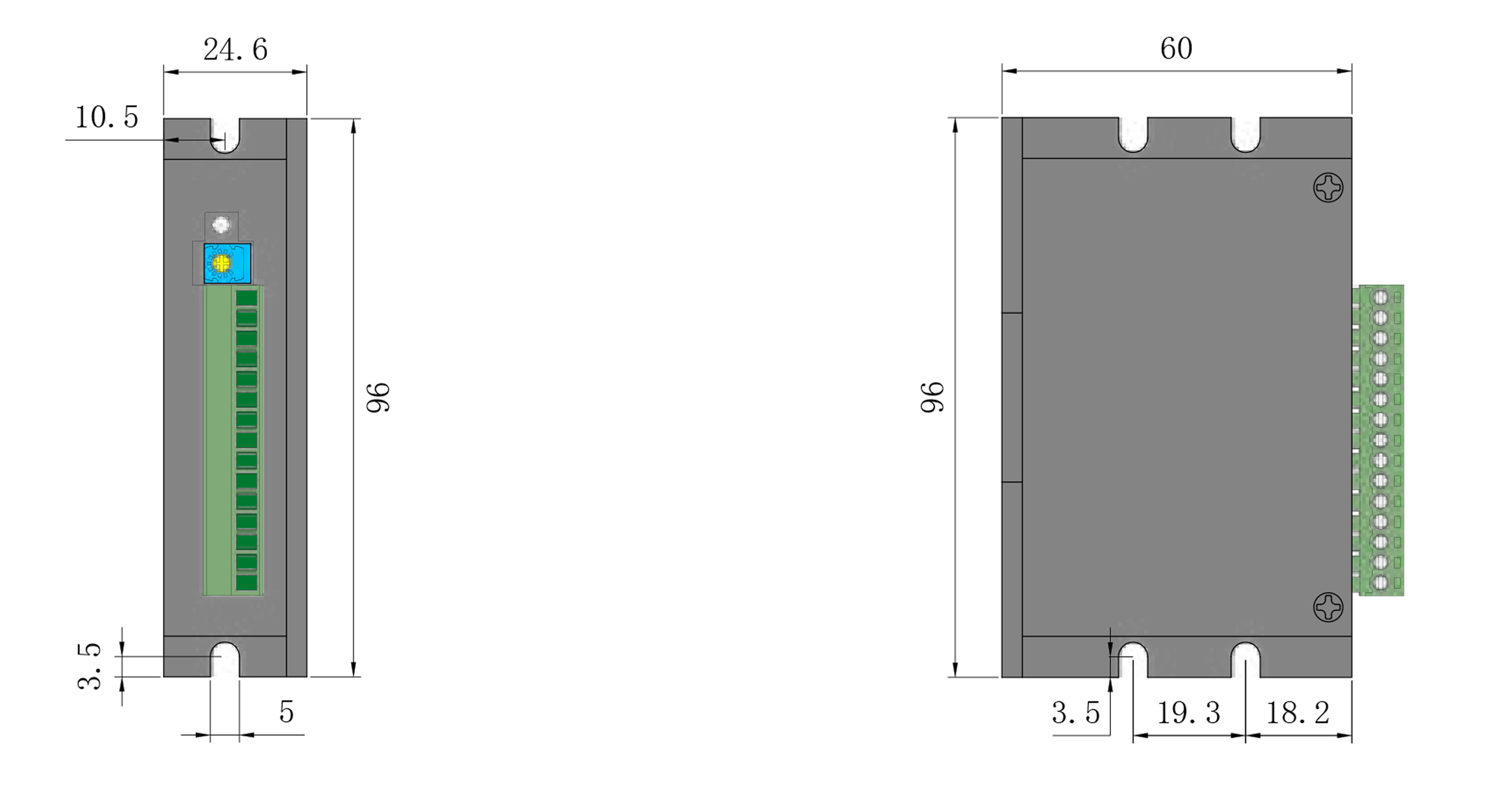

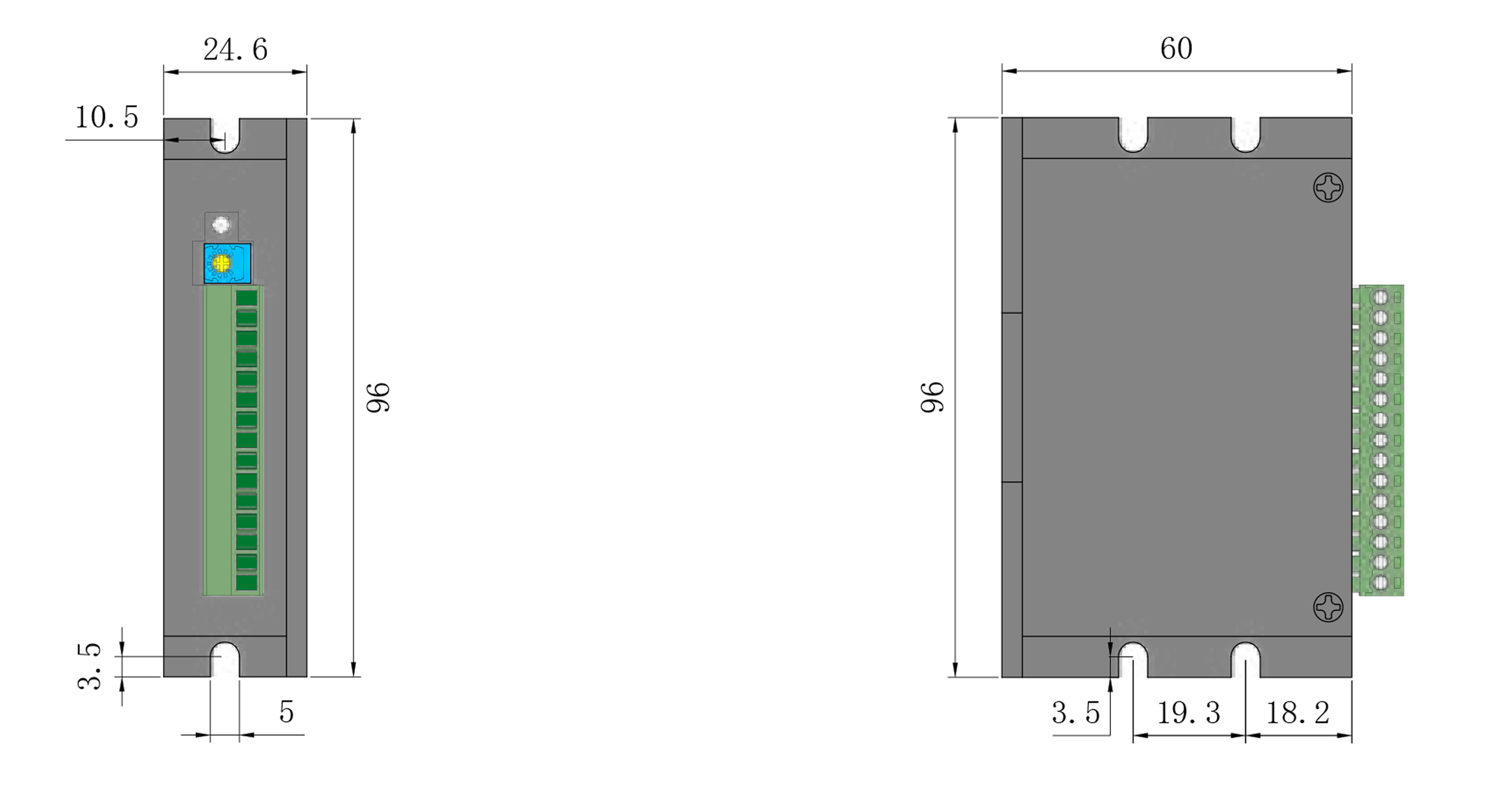

| Brand | Leanmotor |

| Model | LMBLD120 |

| Driver Type | DC Brushless Motor Driver |

| DC / AC | DC |

| Suitable Motor | 3-Phase DC Brushless motor |

| Input Voltage | 12VDC - 30VDC ,Rated 24V |

| Output Current | Max 8A |

| Hall signal voltage | 5V |

| Hall drive current | 20mA |

| Motor speed range | 0rpm - 20000rpm |

| External potentiometer | 10kΩ |

| LMBLD120 DC brushless driver is suitable for speed regulation of three-phase DC brushless motors with power below 120W, and it can provide external potentiometer speed regulation, external analog voltage speed regulation, and PWM speed regulation of upper computer (PLC, microcontroller, etc.). At the same time the driver has a large torque start, fast start and braking, forward and reverse switching, manual and automatic speed control. It is suitable for DC brushless motors with voltage from 12V to 30V and power below 120W. | |

| Parameter | Min | Typical | Max | Unit |

| Voltage Input DC | 12 | 24 | 30 | V |

| Output current | - | - | 8 | A |

| Motor speed range | 0 | - | 20000 | RPM |

| Hall signal voltage | - | - | 5 | V |

| Hall drive current | - | 20 | - | MA |

| External potentiometer | - | 10 | - | KΩ |

| Heat Sinking Method | Natural cooling or fan-forced cooling |

| Atmosphere | Avoid dust, oily mist and corrosive air |

| Operating Temperature | 0 ~ +40℃ |

| Ambient Humidity | 90% or less (non-condensing) |

| Vibration Resistance | 5.7m/s² maximum |

| Storage Temperature | 0 ~ +50℃ |

| Signal category | Terminal | Functional Description |

| Control signal | BRK | Motor brake stop control signal; BRK and COM connect in default, motor brake stops when BRK and COM disconnect. |

| EN | Stop signal terminal; EN connects COM, motor runs, otherwise motor stops. | |

| F/R | Motor direction control terminal; F/R and COM disconnect, motor will rotates clockwise, and otherwise, motor will rotate anticlockwise.l | |

| COM | Common port(0V) | |

| SV | ① External potentiometer speed setting input; ② External analog voltage input terminal ③ PWM speed setting input | |

| Hall signal | REF+ | Hall sensor signal power supply+ |

| HU | Hall sensor signal Hu | |

| HV | Hall sensor signal Hv | |

| HW | Hall sensor signal Hw | |

| REF- | Hall sensor signal - | |

| Motor connection | W | Motor line W phase |

| V | Motor line V phase | |

| U | Motor line U phase | |

Power connection | DC+ | Power supply positive electrode (12-30VDC) |

| DC- | Power supply negative electrode (Hall sensor negative electrode) |

| Brand | Leanmotor |

| Model | LMBLD120 |

| Driver Type | DC Brushless Motor Driver |

| DC / AC | DC |

| Suitable Motor | 3-Phase DC Brushless motor |

| Input Voltage | 12VDC - 30VDC ,Rated 24V |

| Output Current | Max 8A |

| Hall signal voltage | 5V |

| Hall drive current | 20mA |

| Motor speed range | 0rpm - 20000rpm |

| External potentiometer | 10kΩ |

| LMBLD120 DC brushless driver is suitable for speed regulation of three-phase DC brushless motors with power below 120W, and it can provide external potentiometer speed regulation, external analog voltage speed regulation, and PWM speed regulation of upper computer (PLC, microcontroller, etc.). At the same time the driver has a large torque start, fast start and braking, forward and reverse switching, manual and automatic speed control. It is suitable for DC brushless motors with voltage from 12V to 30V and power below 120W. | |

| Parameter | Min | Typical | Max | Unit |

| Voltage Input DC | 12 | 24 | 30 | V |

| Output current | - | - | 8 | A |

| Motor speed range | 0 | - | 20000 | RPM |

| Hall signal voltage | - | - | 5 | V |

| Hall drive current | - | 20 | - | MA |

| External potentiometer | - | 10 | - | KΩ |

| Heat Sinking Method | Natural cooling or fan-forced cooling |

| Atmosphere | Avoid dust, oily mist and corrosive air |

| Operating Temperature | 0 ~ +40℃ |

| Ambient Humidity | 90% or less (non-condensing) |

| Vibration Resistance | 5.7m/s² maximum |

| Storage Temperature | 0 ~ +50℃ |

| Signal category | Terminal | Functional Description |

| Control signal | BRK | Motor brake stop control signal; BRK and COM connect in default, motor brake stops when BRK and COM disconnect. |

| EN | Stop signal terminal; EN connects COM, motor runs, otherwise motor stops. | |

| F/R | Motor direction control terminal; F/R and COM disconnect, motor will rotates clockwise, and otherwise, motor will rotate anticlockwise.l | |

| COM | Common port(0V) | |

| SV | ① External potentiometer speed setting input; ② External analog voltage input terminal ③ PWM speed setting input | |

| Hall signal | REF+ | Hall sensor signal power supply+ |

| HU | Hall sensor signal Hu | |

| HV | Hall sensor signal Hv | |

| HW | Hall sensor signal Hw | |

| REF- | Hall sensor signal - | |

| Motor connection | W | Motor line W phase |

| V | Motor line V phase | |

| U | Motor line U phase | |

Power connection | DC+ | Power supply positive electrode (12-30VDC) |

| DC- | Power supply negative electrode (Hall sensor negative electrode) |

1, Q: The motor does not turn and no holding torque:

A: ① check whether the power line is connected to the wrong voltage is too low, need to increase the voltage or correct the power line

② check whether the motor wiring is correct, if not correct motor wiring. Check if the motor wiring is correct, if not, correct the motor wiring.

③ Whether the enable signal is valid, resulting in the motor does not work.

④ Is the subdividing parameter correct?

⑤ Is the current parameter correct?

2、Q:Motor does not rotate but has holding torque:

A: ① The phase sequence of motor wires is wrong, need to swap any two wires.

② Pulse signal input is wrong, need to check the pulse wiring.

3、Q: The motor torque is too small:

A: ① Phase current setting is too small, need to set the phase current corresponding to the motor.

② acceleration is too fast, reduce the acceleration value

③ motor blocking, need to rule out mechanical problems

④ drive and motor mismatch, need to replace the appropriate drive

4、Q:Motor steering error:

A: ① motor line phase sequence is wrong, need to swap any two wires

② motor line has a broken circuit, check and connect the right

5、Q:The alarm indicator light is on:

A: ① Is the motor wire connected incorrectly

② Whether there is over-voltage and under-voltage conditions

③ Motor or driver is damaged

6、Q:Motor acceleration blocking:

A: ① short acceleration time

② motor torque is too small

③ Low voltage or current

1, Q: The motor does not turn and no holding torque:

A: ① check whether the power line is connected to the wrong voltage is too low, need to increase the voltage or correct the power line

② check whether the motor wiring is correct, if not correct motor wiring. Check if the motor wiring is correct, if not, correct the motor wiring.

③ Whether the enable signal is valid, resulting in the motor does not work.

④ Is the subdividing parameter correct?

⑤ Is the current parameter correct?

2、Q:Motor does not rotate but has holding torque:

A: ① The phase sequence of motor wires is wrong, need to swap any two wires.

② Pulse signal input is wrong, need to check the pulse wiring.

3、Q: The motor torque is too small:

A: ① Phase current setting is too small, need to set the phase current corresponding to the motor.

② acceleration is too fast, reduce the acceleration value

③ motor blocking, need to rule out mechanical problems

④ drive and motor mismatch, need to replace the appropriate drive

4、Q:Motor steering error:

A: ① motor line phase sequence is wrong, need to swap any two wires

② motor line has a broken circuit, check and connect the right

5、Q:The alarm indicator light is on:

A: ① Is the motor wire connected incorrectly

② Whether there is over-voltage and under-voltage conditions

③ Motor or driver is damaged

6、Q:Motor acceleration blocking:

A: ① short acceleration time

② motor torque is too small

③ Low voltage or current