- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

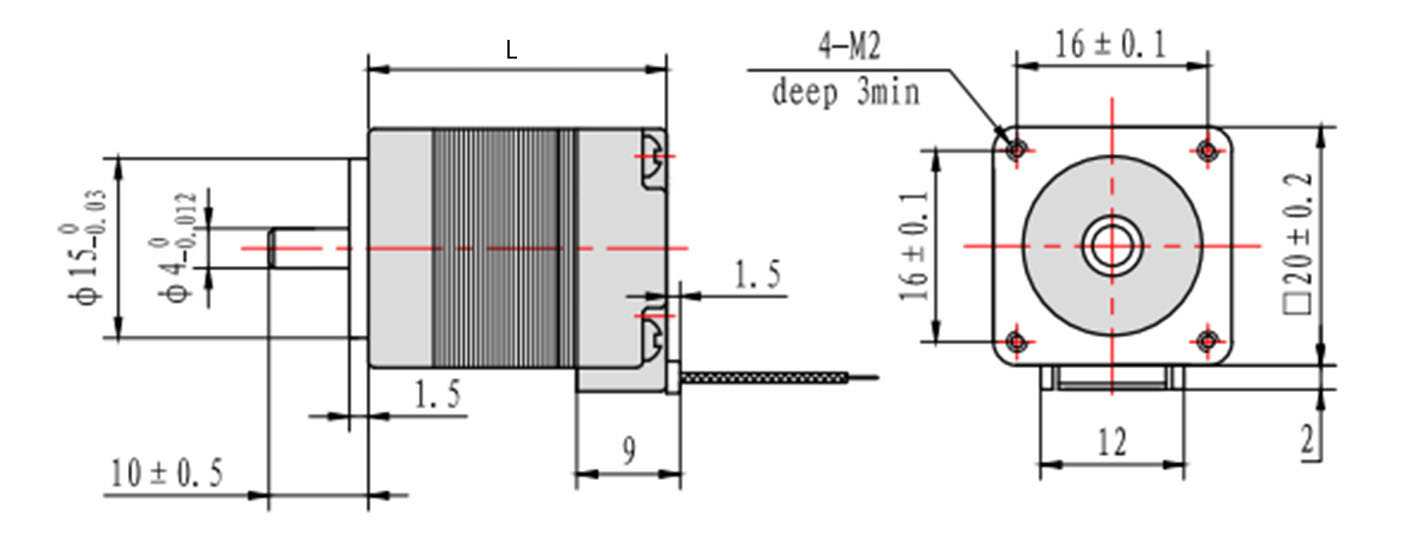

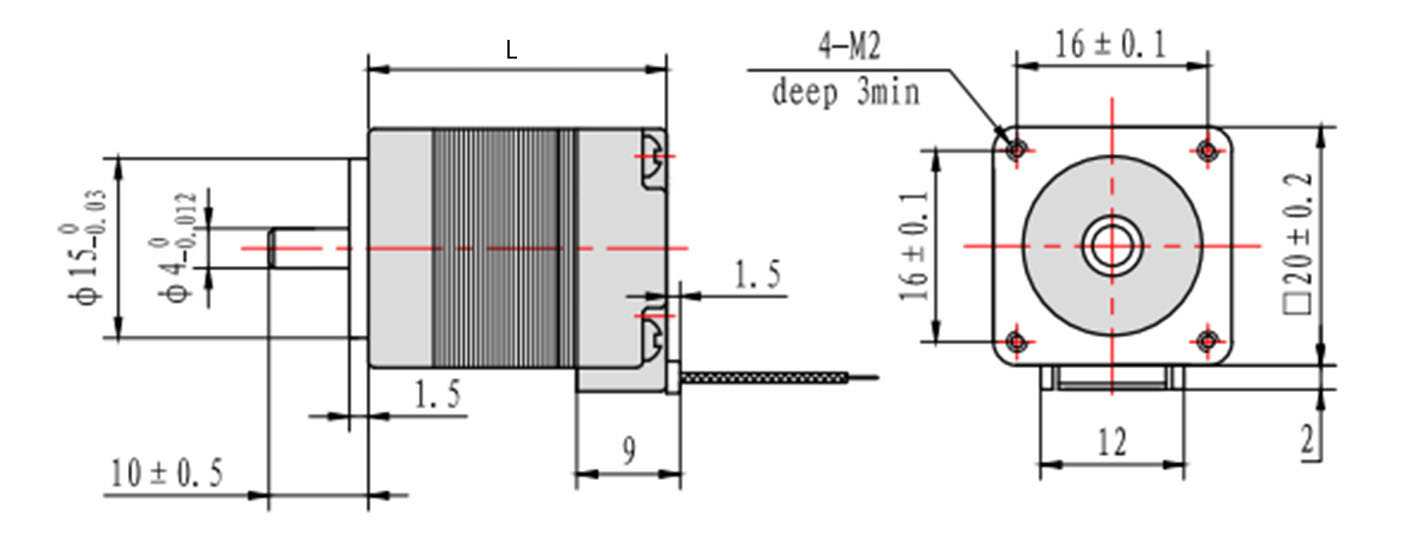

Motor Length: 30mm / 33mm / 38mm / 42mm

| Availability: | |

|---|---|

| Quantity: | |

Nema 8 Hybrid Stepper Motor

LEANMOTOR

Open Loop Motors

Nema8 (20mm)

4wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | kg | |

| LM20HS30-0604 | 1.8 | 30 | 0.6 | 18 | 3.2 | 180 | 4 | 0.06 |

| LM20HS33-0604 | 1.8 | 33 | 0.6 | 6.5 | 1.7 | 200 | 4 | 0.07 |

| LM20HS38-0604 | 1.8 | 38 | 0.6 | 10 | 5.5 | 300 | 4 | 0.08 |

| LM20HS42-0804 | 1.8 | 42 | 0.8 | 5.4 | 1.5 | 400 | 4 | 0.09 |

| LM20HS51-0604 | 1.8 | 51 | 0.6 | 8.2 | 3.2 | 420 | 4 | 0.08 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | kg | |

| LM20HS30-0604 | 1.8 | 30 | 0.6 | 18 | 3.2 | 180 | 4 | 0.06 |

| LM20HS33-0604 | 1.8 | 33 | 0.6 | 6.5 | 1.7 | 200 | 4 | 0.07 |

| LM20HS38-0604 | 1.8 | 38 | 0.6 | 10 | 5.5 | 300 | 4 | 0.08 |

| LM20HS42-0804 | 1.8 | 42 | 0.8 | 5.4 | 1.5 | 400 | 4 | 0.09 |

| LM20HS51-0604 | 1.8 | 51 | 0.6 | 8.2 | 3.2 | 420 | 4 | 0.08 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

1. What is a NEMA 8 hybrid stepping motor?

A NEMA 8 hybrid stepping motor is a compact 0.8-inch (20 mm) frame stepper motor that combines the features of permanent magnet and variable reluctance motors for high precision in a very small size.

2. What are the advantages of a hybrid stepping motor?

Hybrid steppers provide higher torque, better step accuracy, smooth motion, and higher holding force compared to standard permanent magnet steppers.

3. What is the standard step angle of a NEMA 8 hybrid stepper?

The standard step angle is 1.8° per step, which can be further improved using microstepping for finer resolution.

4. What applications are suitable for NEMA 8 hybrid stepping motors?

They are ideal for compact automation devices, medical equipment, optical instruments, small robotics, and precision positioning systems.

5. How much torque can a NEMA 8 hybrid stepper generate?

Torque depends on motor winding, length, and current; despite its small size, it delivers sufficient torque for light-load precision applications.

6. Can the motor operate continuously?

Yes, it is designed for continuous operation within its rated thermal limits.

7. What makes a hybrid stepper different from a permanent magnet stepper?

Hybrid steppers combine the benefits of permanent magnet and variable reluctance designs for improved torque, accuracy, and performance at higher speeds.

8. Can the motor operate at high speeds?

Yes, hybrid stepper motors are suitable for moderate to high-speed applications while maintaining accuracy.

9. Is a driver required to operate a NEMA 8 hybrid stepper?

Yes, a compatible stepper motor driver or controller is required to control steps and microstepping.

10. How precise is this motor for micro-positioning applications?

With microstepping, NEMA 8 hybrid steppers can achieve high positional resolution suitable for miniature precision systems.

11. Can the NEMA 8 hybrid stepping motor be customized?

Yes, motor torque, winding, voltage, current, and step angle can all be customized.

12. Are different shaft types available?

Yes, round shafts, D-shafts, keyed shafts, or custom-machined shafts can be provided.

13. Can encoders or sensors be added?

Yes, Hall sensors or incremental encoders can be integrated for closed-loop control.

14. Can the motor be supplied with a matching driver?

Yes, compatible stepper motor drivers can be supplied for optimized performance.

15. Can low-noise or vibration-optimized versions be produced?

Yes, winding optimization, precise construction, and microstepping help reduce noise and vibration.

16. Can the motor be adapted for harsh environments?

Yes, IP-rated protection, special coatings, or high-temperature insulation can be applied.

17. Can the motor be customized for specific applications?

Yes, stroke length, torque, and electrical specifications can be tailored to fit compact or high-precision systems.

18. What quality tests are performed on the motor?

Testing includes step accuracy, holding torque, insulation resistance, thermal performance, and durability.

19. What is the typical lead time for customized NEMA 8 motors?

Prototype samples typically take 2–4 weeks, while mass production takes 4–8 weeks.

20. How does factory-level customization improve system performance?

Customization ensures optimal torque, step resolution, and electrical matching, improving precision, reliability, and system lifetime.

1. What is a NEMA 8 hybrid stepping motor?

A NEMA 8 hybrid stepping motor is a compact 0.8-inch (20 mm) frame stepper motor that combines the features of permanent magnet and variable reluctance motors for high precision in a very small size.

2. What are the advantages of a hybrid stepping motor?

Hybrid steppers provide higher torque, better step accuracy, smooth motion, and higher holding force compared to standard permanent magnet steppers.

3. What is the standard step angle of a NEMA 8 hybrid stepper?

The standard step angle is 1.8° per step, which can be further improved using microstepping for finer resolution.

4. What applications are suitable for NEMA 8 hybrid stepping motors?

They are ideal for compact automation devices, medical equipment, optical instruments, small robotics, and precision positioning systems.

5. How much torque can a NEMA 8 hybrid stepper generate?

Torque depends on motor winding, length, and current; despite its small size, it delivers sufficient torque for light-load precision applications.

6. Can the motor operate continuously?

Yes, it is designed for continuous operation within its rated thermal limits.

7. What makes a hybrid stepper different from a permanent magnet stepper?

Hybrid steppers combine the benefits of permanent magnet and variable reluctance designs for improved torque, accuracy, and performance at higher speeds.

8. Can the motor operate at high speeds?

Yes, hybrid stepper motors are suitable for moderate to high-speed applications while maintaining accuracy.

9. Is a driver required to operate a NEMA 8 hybrid stepper?

Yes, a compatible stepper motor driver or controller is required to control steps and microstepping.

10. How precise is this motor for micro-positioning applications?

With microstepping, NEMA 8 hybrid steppers can achieve high positional resolution suitable for miniature precision systems.

11. Can the NEMA 8 hybrid stepping motor be customized?

Yes, motor torque, winding, voltage, current, and step angle can all be customized.

12. Are different shaft types available?

Yes, round shafts, D-shafts, keyed shafts, or custom-machined shafts can be provided.

13. Can encoders or sensors be added?

Yes, Hall sensors or incremental encoders can be integrated for closed-loop control.

14. Can the motor be supplied with a matching driver?

Yes, compatible stepper motor drivers can be supplied for optimized performance.

15. Can low-noise or vibration-optimized versions be produced?

Yes, winding optimization, precise construction, and microstepping help reduce noise and vibration.

16. Can the motor be adapted for harsh environments?

Yes, IP-rated protection, special coatings, or high-temperature insulation can be applied.

17. Can the motor be customized for specific applications?

Yes, stroke length, torque, and electrical specifications can be tailored to fit compact or high-precision systems.

18. What quality tests are performed on the motor?

Testing includes step accuracy, holding torque, insulation resistance, thermal performance, and durability.

19. What is the typical lead time for customized NEMA 8 motors?

Prototype samples typically take 2–4 weeks, while mass production takes 4–8 weeks.

20. How does factory-level customization improve system performance?

Customization ensures optimal torque, step resolution, and electrical matching, improving precision, reliability, and system lifetime.