- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Motor Length: 30mm / 38mm

| Availability: | |

|---|---|

| Quantity: | |

Nema 8 Hollow Shaft Stepper Motor

LEANMOTOR

Hollow Shaft Motors

Nema8 (20mm)

4wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

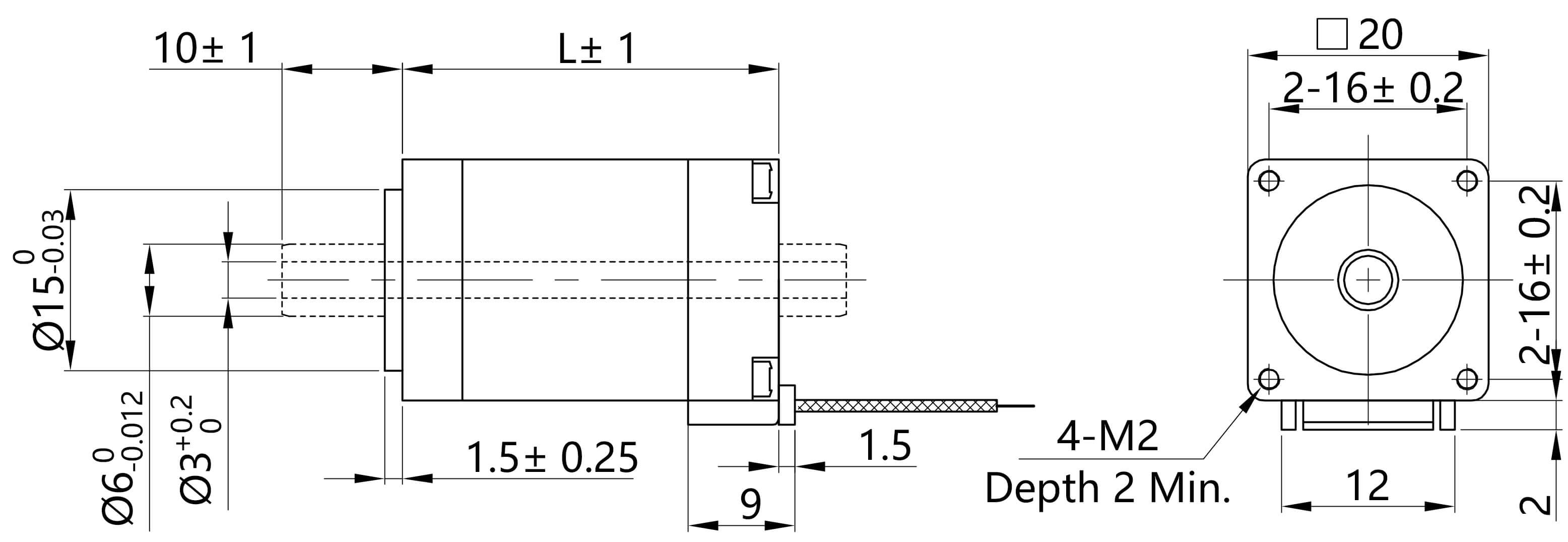

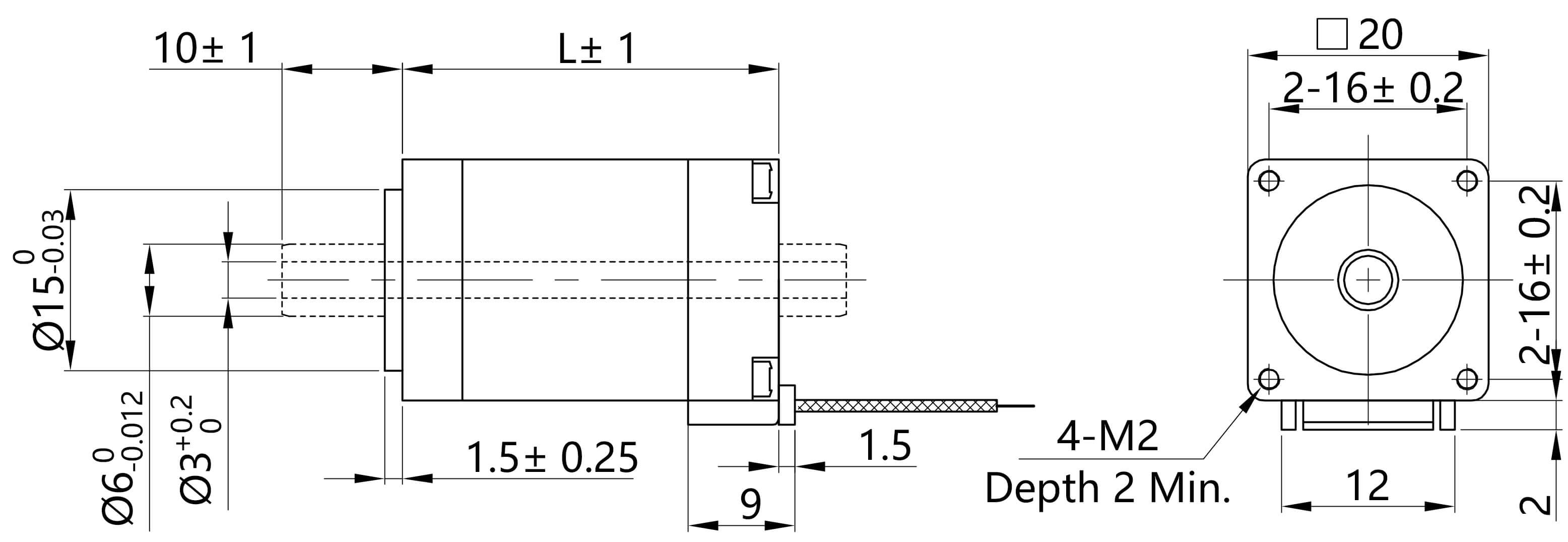

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm | kg | |

| LM20HSH30-0604 | 1.8 | 30 | 0.6 | 6.5 | 1.7 | 180 | 4 | 2 | 0.05 |

| LM20HSH38-0604 | 1.8 | 38 | 0.6 | 9 | 3 | 220 | 4 | 3 | 0.08 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm | kg | |

| LM20HSH30-0604 | 1.8 | 30 | 0.6 | 6.5 | 1.7 | 180 | 4 | 2 | 0.05 |

| LM20HSH38-0604 | 1.8 | 38 | 0.6 | 9 | 3 | 220 | 4 | 3 | 0.08 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

1. What is a NEMA 8 hollow shaft stepping motor?

A NEMA 8 hollow shaft stepper motor is an ultra-compact stepper motor with a hollow output shaft, allowing direct coupling of shafts, gears, or other components for precision motion applications.

2. What are the main advantages of hollow shaft stepper motors?

Hollow shaft motors enable direct mounting of driven components, reduce mechanical complexity, save space, and improve alignment accuracy.

3. What industries commonly use NEMA 8 hollow shaft motors?

Applications include robotics, medical devices, lab automation, instrumentation, and compact automation equipment where space is limited.

4. What is the typical step angle of a NEMA 8 stepper motor?

Most NEMA 8 motors have a 1.8° step angle, providing 200 steps per revolution, with microstepping options for higher precision.

5. How much torque can a NEMA 8 hollow shaft stepper motor deliver?

Torque is relatively small due to the compact size, but suitable for micro-precision applications. Torque can be optimized with microstepping or gear integration.

6. Can NEMA 8 hollow shaft motors operate at high speeds?

Yes, they can operate efficiently at moderate to high speeds depending on load and control method, but torque decreases at higher speeds.

7. Are NEMA 8 stepper motors suitable for continuous-duty operation?

Yes, when operated within rated current and thermal limits, these motors can run continuously with reliable performance.

8. Can hollow shaft stepper motors reduce backlash in mechanical systems?

Yes, direct coupling reduces intermediate components, minimizing backlash and improving positional accuracy.

9. What control methods are compatible with NEMA 8 hollow shaft stepper motors?

They can be controlled using standard stepper drivers, microstepping drivers, or advanced motion controllers for smooth operation.

10. How compact are NEMA 8 hollow shaft motors compared to other stepper motors?

They are among the smallest stepper motors available, making them ideal for miniaturized or space-constrained applications.

11. Can the factory customize NEMA 8 hollow shaft stepper motors for specific torque requirements?

Yes, winding types, current ratings, and voltage can be tailored to meet the torque needs of precision applications.

12. Can the hollow shaft diameter be customized?

Yes, manufacturers can provide different hollow shaft diameters to fit specific mechanical coupling requirements.

13. Is it possible to customize the step angle or microstepping resolution?

Yes, factories can design the motor for standard 1.8° steps or optimize it for microstepping to achieve higher positional accuracy.

14. Can NEMA 8 motors be integrated with encoders for closed-loop control?

Yes, incremental or absolute encoders can be added for feedback-based closed-loop motion control.

15. Are low-noise or vibration-optimized versions available?

Yes, specialized winding and bearing designs, combined with smooth driver control, can reduce vibration and operational noise.

16. Can the motor's mounting flange or shaft length be customized?

Yes, mounting flanges and shaft lengths can be modified to meet specific mechanical integration requirements.

17. Are waterproof or dustproof options available?

Yes, IP-rated housings (such as IP54 or higher) can be applied for harsh environmental conditions.

18. Does the factory offer OEM/ODM services for NEMA 8 hollow shaft motors?

Yes, factories provide full OEM and ODM services, including motor labeling, mechanical integration, and system-level design.

19. What is the typical lead time for custom NEMA 8 hollow shaft stepper motors?

Prototyping usually takes 2–3 weeks, while mass production typically requires 4–6 weeks, depending on customization complexity.

20. How does factory customization improve motor performance?

Tailoring shaft size, torque, step angle, and optional sensors ensures optimal alignment with your application, increasing precision, efficiency, and system reliability.

1. What is a NEMA 8 hollow shaft stepping motor?

A NEMA 8 hollow shaft stepper motor is an ultra-compact stepper motor with a hollow output shaft, allowing direct coupling of shafts, gears, or other components for precision motion applications.

2. What are the main advantages of hollow shaft stepper motors?

Hollow shaft motors enable direct mounting of driven components, reduce mechanical complexity, save space, and improve alignment accuracy.

3. What industries commonly use NEMA 8 hollow shaft motors?

Applications include robotics, medical devices, lab automation, instrumentation, and compact automation equipment where space is limited.

4. What is the typical step angle of a NEMA 8 stepper motor?

Most NEMA 8 motors have a 1.8° step angle, providing 200 steps per revolution, with microstepping options for higher precision.

5. How much torque can a NEMA 8 hollow shaft stepper motor deliver?

Torque is relatively small due to the compact size, but suitable for micro-precision applications. Torque can be optimized with microstepping or gear integration.

6. Can NEMA 8 hollow shaft motors operate at high speeds?

Yes, they can operate efficiently at moderate to high speeds depending on load and control method, but torque decreases at higher speeds.

7. Are NEMA 8 stepper motors suitable for continuous-duty operation?

Yes, when operated within rated current and thermal limits, these motors can run continuously with reliable performance.

8. Can hollow shaft stepper motors reduce backlash in mechanical systems?

Yes, direct coupling reduces intermediate components, minimizing backlash and improving positional accuracy.

9. What control methods are compatible with NEMA 8 hollow shaft stepper motors?

They can be controlled using standard stepper drivers, microstepping drivers, or advanced motion controllers for smooth operation.

10. How compact are NEMA 8 hollow shaft motors compared to other stepper motors?

They are among the smallest stepper motors available, making them ideal for miniaturized or space-constrained applications.

11. Can the factory customize NEMA 8 hollow shaft stepper motors for specific torque requirements?

Yes, winding types, current ratings, and voltage can be tailored to meet the torque needs of precision applications.

12. Can the hollow shaft diameter be customized?

Yes, manufacturers can provide different hollow shaft diameters to fit specific mechanical coupling requirements.

13. Is it possible to customize the step angle or microstepping resolution?

Yes, factories can design the motor for standard 1.8° steps or optimize it for microstepping to achieve higher positional accuracy.

14. Can NEMA 8 motors be integrated with encoders for closed-loop control?

Yes, incremental or absolute encoders can be added for feedback-based closed-loop motion control.

15. Are low-noise or vibration-optimized versions available?

Yes, specialized winding and bearing designs, combined with smooth driver control, can reduce vibration and operational noise.

16. Can the motor's mounting flange or shaft length be customized?

Yes, mounting flanges and shaft lengths can be modified to meet specific mechanical integration requirements.

17. Are waterproof or dustproof options available?

Yes, IP-rated housings (such as IP54 or higher) can be applied for harsh environmental conditions.

18. Does the factory offer OEM/ODM services for NEMA 8 hollow shaft motors?

Yes, factories provide full OEM and ODM services, including motor labeling, mechanical integration, and system-level design.

19. What is the typical lead time for custom NEMA 8 hollow shaft stepper motors?

Prototyping usually takes 2–3 weeks, while mass production typically requires 4–6 weeks, depending on customization complexity.

20. How does factory customization improve motor performance?

Tailoring shaft size, torque, step angle, and optional sensors ensures optimal alignment with your application, increasing precision, efficiency, and system reliability.