- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 4A

Resistance: 0.65/0.7Ω

Rated Torque: 3/4N.m

| Availability: | |

|---|---|

| Quantity: | |

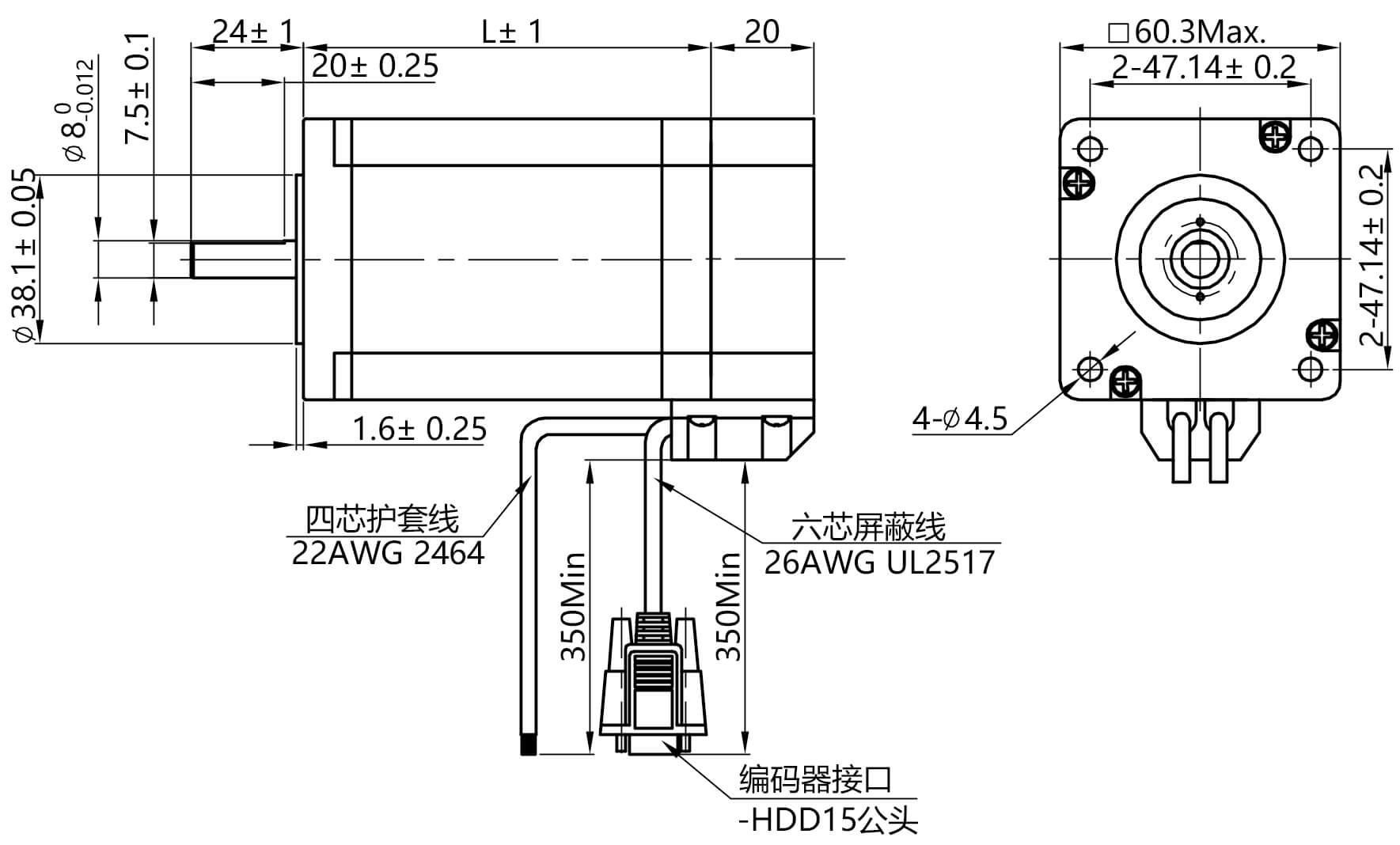

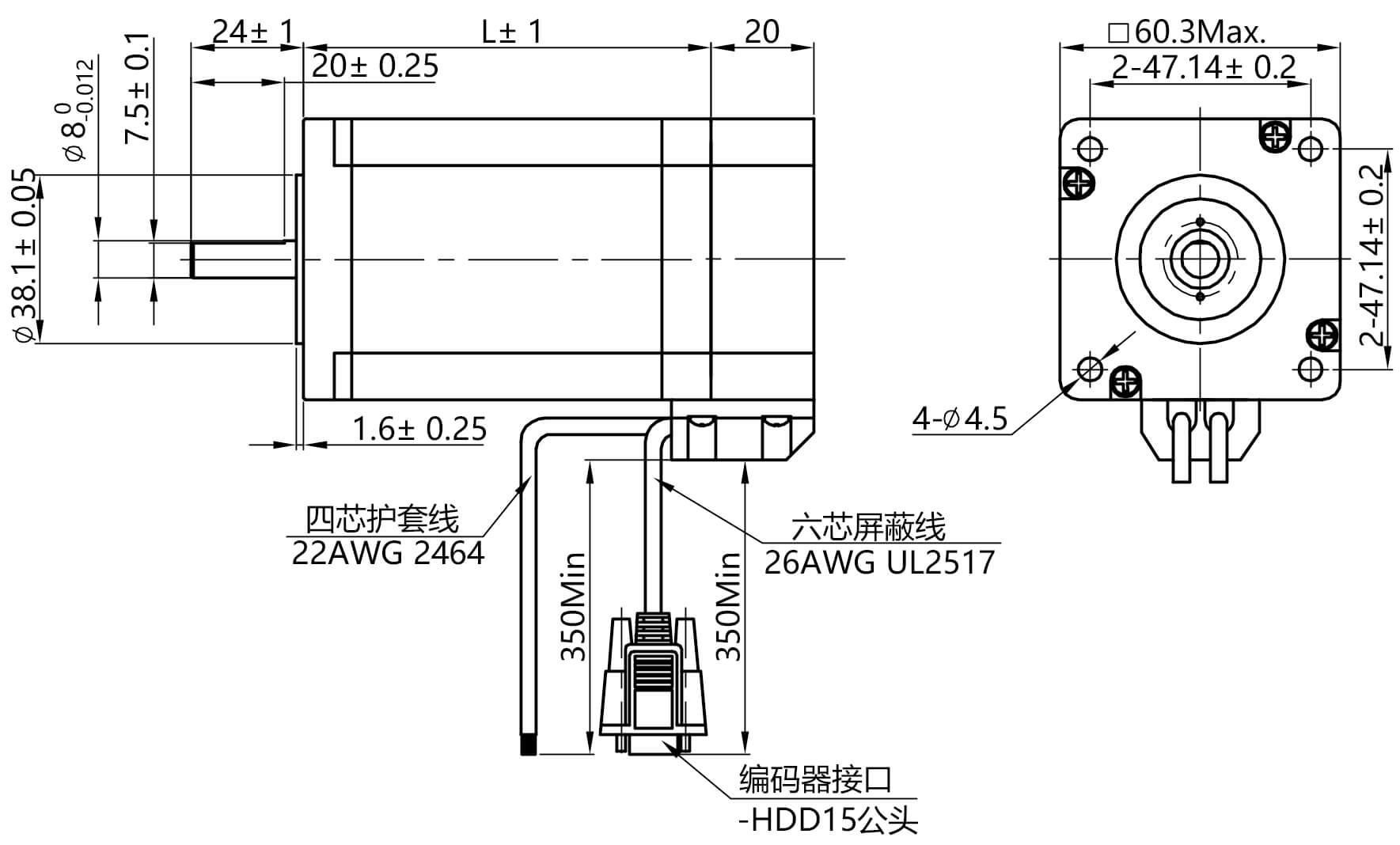

Nema 24 Hybrid Close Loop Stepper Motor

LeanMotor

Closed Loop Motors

Nema24 (60mm)

4wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength1 | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 75N (20mm from the flange) |

| Max. axial force | 15N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm2 | Kg | |

| LM60HSN30 | 1.8 | 100 | 4 | 0.65 | 2.4 | 3 | 4 | 980 | 1.7 |

| LM60HSN40 | 1.8 | 111 | 4 | 0.70 | 3 | 4 | 4 | 1120 | 1.9 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength1 | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 75N (20mm from the flange) |

| Max. axial force | 15N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm2 | Kg | |

| LM60HSN30 | 1.8 | 100 | 4 | 0.65 | 2.4 | 3 | 4 | 980 | 1.7 |

| LM60HSN40 | 1.8 | 111 | 4 | 0.70 | 3 | 4 | 4 | 1120 | 1.9 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

A NEMA 24 hybrid closed-loop stepping motor is a stepper motor equipped with an encoder that provides real-time position feedback, eliminating step loss and improving reliability.

Closed-loop motors use encoder feedback to correct position errors, while open-loop motors operate without feedback and may lose steps under overload.

Key advantages include no step loss, higher torque utilization, reduced heat, smoother motion, and improved system efficiency.

NEMA 24 indicates a motor frame size of approximately 60 × 60 mm, suitable for medium to high torque applications.

With encoder feedback and microstepping control, it provides high positioning accuracy and excellent repeatability.

Yes, closed-loop control allows higher speeds with stable torque and reduced resonance.

No complex tuning is required; closed-loop steppers combine the simplicity of stepper motors with servo-like feedback.

They are widely used in CNC machines, automation equipment, packaging machines, semiconductor equipment, and robotics.

Most NEMA 24 closed-loop stepper motors use high-resolution optical or magnetic encoders.

In many medium-power applications, it offers a cost-effective alternative to servo motors with sufficient performance.

Yes, manufacturers can customize torque ratings, motor length, winding parameters, and encoder specifications.

Yes, planetary gearboxes or other reducers can be integrated to increase output torque and precision.

Factories can offer various encoder resolutions to meet different accuracy and control requirements.

Yes, manufacturers often provide optimized closed-loop drivers for plug-and-play integration.

Yes, optimized electromagnetic design, precision bearings, and advanced control algorithms reduce noise and vibration.

Yes, options include IP-rated protection, high-temperature windings, and reinforced housings.

Testing includes encoder accuracy testing, torque testing, thermal testing, vibration testing, and endurance testing.

Yes, motor length, shaft design, and connector orientation can be optimized for space-constrained designs.

Prototype samples typically take 2–4 weeks, while mass production usually takes 4–8 weeks.

Customization ensures precise matching of motor, encoder, and driver to the application, improving efficiency, accuracy, and long-term reliability.

A NEMA 24 hybrid closed-loop stepping motor is a stepper motor equipped with an encoder that provides real-time position feedback, eliminating step loss and improving reliability.

Closed-loop motors use encoder feedback to correct position errors, while open-loop motors operate without feedback and may lose steps under overload.

Key advantages include no step loss, higher torque utilization, reduced heat, smoother motion, and improved system efficiency.

NEMA 24 indicates a motor frame size of approximately 60 × 60 mm, suitable for medium to high torque applications.

With encoder feedback and microstepping control, it provides high positioning accuracy and excellent repeatability.

Yes, closed-loop control allows higher speeds with stable torque and reduced resonance.

No complex tuning is required; closed-loop steppers combine the simplicity of stepper motors with servo-like feedback.

They are widely used in CNC machines, automation equipment, packaging machines, semiconductor equipment, and robotics.

Most NEMA 24 closed-loop stepper motors use high-resolution optical or magnetic encoders.

In many medium-power applications, it offers a cost-effective alternative to servo motors with sufficient performance.

Yes, manufacturers can customize torque ratings, motor length, winding parameters, and encoder specifications.

Yes, planetary gearboxes or other reducers can be integrated to increase output torque and precision.

Factories can offer various encoder resolutions to meet different accuracy and control requirements.

Yes, manufacturers often provide optimized closed-loop drivers for plug-and-play integration.

Yes, optimized electromagnetic design, precision bearings, and advanced control algorithms reduce noise and vibration.

Yes, options include IP-rated protection, high-temperature windings, and reinforced housings.

Testing includes encoder accuracy testing, torque testing, thermal testing, vibration testing, and endurance testing.

Yes, motor length, shaft design, and connector orientation can be optimized for space-constrained designs.

Prototype samples typically take 2–4 weeks, while mass production usually takes 4–8 weeks.

Customization ensures precise matching of motor, encoder, and driver to the application, improving efficiency, accuracy, and long-term reliability.