- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

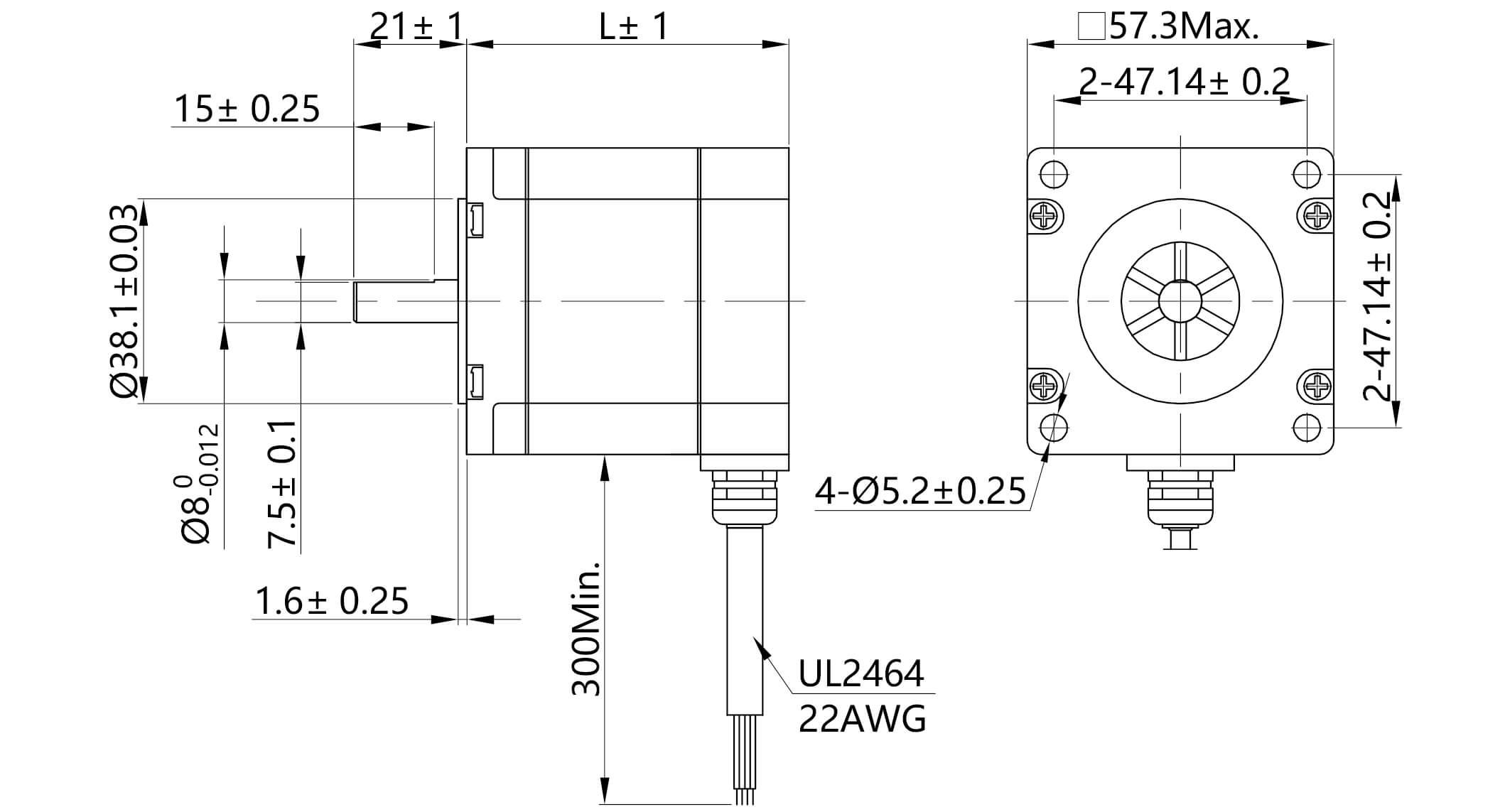

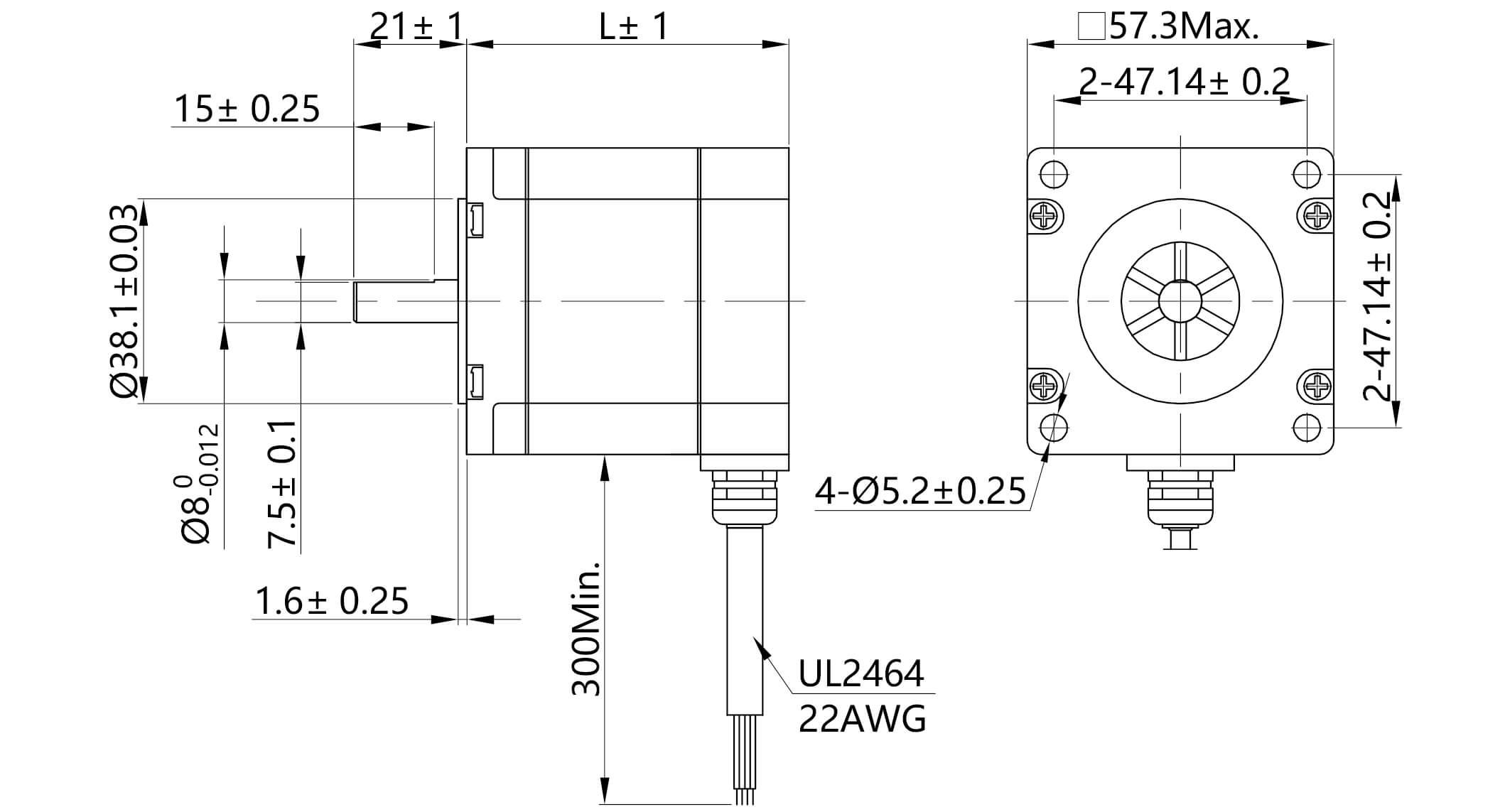

Motor Length: 51mm / 56mm / 76mm / 82mm / 100mm /112mm

| Availability: | |

|---|---|

| Quantity: | |

Nema 23 Waterproof Stepper Motor

LEANMOTOR

Waterproof Motors

Nema23 (57mm)

4wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm² | kg | |

| LM57HSW51-2804 | 1.8 | 51 | 2.8 | 0.83 | 2.2 | 1 | 4 | 230 | 0.59 |

| LM57HSW56-2804 | 1.8 | 56 | 2.8 | 0.9 | 3 | 1.2 | 4 | 280 | 0.68 |

| LM57HSW76-2804 | 1.8 | 76 | 2.8 | 1.1 | 3.6 | 1.89 | 4 | 440 | 1.1 |

| LM57HSW82-3004 | 1.8 | 82 | 3 | 1.2 | 4 | 2.1 | 4 | 600 | 1.1 |

| LM57HSW100-3004 | 1.8 | 100 | 3 | 0.75 | 3 | 2.8 | 4 | 700 | 1.3 |

| LM57HSW112-3004 | 1.8 | 112 | 3 | 1.6 | 7.5 | 3 | 4 | 800 | 1.4 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm² | kg | |

| LM57HSW51-2804 | 1.8 | 51 | 2.8 | 0.83 | 2.2 | 1 | 4 | 230 | 0.59 |

| LM57HSW56-2804 | 1.8 | 56 | 2.8 | 0.9 | 3 | 1.2 | 4 | 280 | 0.68 |

| LM57HSW76-2804 | 1.8 | 76 | 2.8 | 1.1 | 3.6 | 1.89 | 4 | 440 | 1.1 |

| LM57HSW82-3004 | 1.8 | 82 | 3 | 1.2 | 4 | 2.1 | 4 | 600 | 1.1 |

| LM57HSW100-3004 | 1.8 | 100 | 3 | 0.75 | 3 | 2.8 | 4 | 700 | 1.3 |

| LM57HSW112-3004 | 1.8 | 112 | 3 | 1.6 | 7.5 | 3 | 4 | 800 | 1.4 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

1. What is a NEMA 23 waterproof stepping motor?

A NEMA 23 waterproof stepping motor is a 57 mm frame stepper motor designed with sealed housing and waterproof construction for operation in wet or dusty environments.

2. What IP rating does a NEMA 23 waterproof stepper motor typically have?

Most waterproof NEMA 23 stepper motors are rated IP65 or higher, protecting against water jets and dust ingress.

3. Where are waterproof NEMA 23 stepper motors commonly used?

They are widely used in food processing equipment, outdoor automation, medical devices, agricultural machinery, and industrial washing systems.

4. How does waterproof design affect motor performance?

The sealed structure protects internal components without compromising torque, accuracy, or reliability.

5. Can a waterproof stepper motor operate in high-humidity environments?

Yes, it is specifically designed to perform reliably in high-humidity and splash-prone conditions.

6. What is the standard step angle of a NEMA 23 waterproof stepping motor?

The standard step angle is 1.8°, with microstepping available for smoother and quieter operation.

7. Does waterproofing reduce heat dissipation?

While sealing can limit airflow, optimized housing materials and thermal design help maintain safe operating temperatures.

8. Can this motor be used in washdown applications?

Yes, when properly rated, it is suitable for light to moderate washdown environments.

9. Is the NEMA 23 waterproof stepper motor compatible with standard drivers?

Yes, it works with most standard stepper motor drivers designed for NEMA 23 motors.

10. How long is the service life of a waterproof NEMA 23 stepper motor?

With proper selection and operation, it offers long service life even in harsh environments.

11. Can NEMA 23 waterproof stepping motors be customized?

Yes, motor torque, winding parameters, voltage, and current ratings can be customized.

12. Are different waterproof levels available?

Yes, IP ratings such as IP65 or higher can be customized based on application requirements.

13. Can special waterproof connectors or cables be used?

Yes, customized waterproof cables, connectors, and gland designs are available.

14. Can encoders be added to waterproof stepper motors?

Yes, sealed encoders can be integrated for closed-loop or feedback applications.

15. Are stainless steel shafts or corrosion-resistant materials available?

Yes, corrosion-resistant shafts, fasteners, and surface treatments can be provided.

16. Can the motor be combined with gearboxes?

Yes, planetary, worm, or spur gearboxes can be integrated while maintaining waterproof performance.

17. What quality tests are performed on waterproof stepper motors?

Testing includes waterproof sealing tests, insulation resistance tests, torque testing, and durability testing.

18. Can the motor be customized for outdoor or marine environments?

Yes, enhanced sealing, anti-corrosion coatings, and reinforced cable exits can be applied.

19. What is the typical lead time for customized waterproof NEMA 23 stepper motors?

Custom samples typically take 2–4 weeks, with mass production in 4–8 weeks.

20. How does factory-level customization improve reliability in wet environments?

Customization ensures optimal sealing, materials, and performance matching for long-term stability and reduced failure risk.

1. What is a NEMA 23 waterproof stepping motor?

A NEMA 23 waterproof stepping motor is a 57 mm frame stepper motor designed with sealed housing and waterproof construction for operation in wet or dusty environments.

2. What IP rating does a NEMA 23 waterproof stepper motor typically have?

Most waterproof NEMA 23 stepper motors are rated IP65 or higher, protecting against water jets and dust ingress.

3. Where are waterproof NEMA 23 stepper motors commonly used?

They are widely used in food processing equipment, outdoor automation, medical devices, agricultural machinery, and industrial washing systems.

4. How does waterproof design affect motor performance?

The sealed structure protects internal components without compromising torque, accuracy, or reliability.

5. Can a waterproof stepper motor operate in high-humidity environments?

Yes, it is specifically designed to perform reliably in high-humidity and splash-prone conditions.

6. What is the standard step angle of a NEMA 23 waterproof stepping motor?

The standard step angle is 1.8°, with microstepping available for smoother and quieter operation.

7. Does waterproofing reduce heat dissipation?

While sealing can limit airflow, optimized housing materials and thermal design help maintain safe operating temperatures.

8. Can this motor be used in washdown applications?

Yes, when properly rated, it is suitable for light to moderate washdown environments.

9. Is the NEMA 23 waterproof stepper motor compatible with standard drivers?

Yes, it works with most standard stepper motor drivers designed for NEMA 23 motors.

10. How long is the service life of a waterproof NEMA 23 stepper motor?

With proper selection and operation, it offers long service life even in harsh environments.

11. Can NEMA 23 waterproof stepping motors be customized?

Yes, motor torque, winding parameters, voltage, and current ratings can be customized.

12. Are different waterproof levels available?

Yes, IP ratings such as IP65 or higher can be customized based on application requirements.

13. Can special waterproof connectors or cables be used?

Yes, customized waterproof cables, connectors, and gland designs are available.

14. Can encoders be added to waterproof stepper motors?

Yes, sealed encoders can be integrated for closed-loop or feedback applications.

15. Are stainless steel shafts or corrosion-resistant materials available?

Yes, corrosion-resistant shafts, fasteners, and surface treatments can be provided.

16. Can the motor be combined with gearboxes?

Yes, planetary, worm, or spur gearboxes can be integrated while maintaining waterproof performance.

17. What quality tests are performed on waterproof stepper motors?

Testing includes waterproof sealing tests, insulation resistance tests, torque testing, and durability testing.

18. Can the motor be customized for outdoor or marine environments?

Yes, enhanced sealing, anti-corrosion coatings, and reinforced cable exits can be applied.

19. What is the typical lead time for customized waterproof NEMA 23 stepper motors?

Custom samples typically take 2–4 weeks, with mass production in 4–8 weeks.

20. How does factory-level customization improve reliability in wet environments?

Customization ensures optimal sealing, materials, and performance matching for long-term stability and reduced failure risk.