- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 0.4-4A

Resistance: 0.7 -30Ω

Rated Torque: 180-720 g.cm

| Availability: | |

|---|---|

| Quantity: | |

Nema 23 Geared Stepper Motor with FLF57 Series Common Planetary Gearbox

LeanMotor

Gearbox Motors

Nema23 (57mm)

4wires, 6wires

2 Phase, 3 Phase

0.9°, 1.2°, 1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° or 0.9° or 1.2° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 75N (20mm from the flange) |

| Max. axial force | 15N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM57HM41-1006 | 0.9 | 41 | 1 | 5.7 | 8 | 3.9 | 6 | 210 | 120 | 0.45 |

| LM57HM41-2804 | 0.9 | 41 | 2.8 | 0.7 | 2.2 | 5 | 4 | 210 | 120 | 0.45 |

| LM57HM51-2006 | 0.9 | 51 | 2 | 1.6 | 2.2 | 7.2 | 6 | 380 | 280 | 0.68 |

| LM57HM56-1006 | 0.9 | 56 | 1 | 7.4 | 17.5 | 9 | 6 | 400 | 300 | 0.7 |

| LM57HM56-2006 | 0.9 | 56 | 2 | 1.8 | 4.5 | 9 | 6 | 400 | 300 | 0.7 |

| LM57HM56-2804 | 0.9 | 56 | 2.8 | 0.9 | 3.3 | 12 | 4 | 400 | 300 | 0.7 |

| LM57HM76-1006 | 0.9 | 76 | 1 | 8.6 | 23 | 13.5 | 6 | 680 | 480 | 1 |

| LM57HM76-2006 | 0.9 | 76 | 2 | 3 | 7 | 13.5 | 6 | 680 | 480 | 1 |

| LM57HM76-2804 | 0.9 | 76 | 2.8 | 1.15 | 5.6 | 18 | 4 | 680 | 480 | 1 |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm | g.cm2 | Kg | |

| LM57HS41-1006 | 1.8 | 41 | 1 | 7.1 | 8 | 0.48 | 6 | 250 | 150 | 0.47 |

| LM57HS41-2008 | 1.8 | 41 | 2 | 1.4 | 1.4 | 0.39 | 8 | 250 | 150 | 0.47 |

| LM57HS41-2804 | 1.8 | 41 | 2.8 | 0.7 | 1.4 | 0.55 | 4 | 250 | 150 | 0.47 |

| LM57HS51-1006 | 1.8 | 51 | 1 | 6.6 | 8.2 | 0.72 | 6 | 300 | 230 | 0.59 |

| LM57HS51-2008 | 1.8 | 51 | 2 | 1.8 | 2.7 | 0.9 | 8 | 300 | 230 | 0.59 |

| LM57HS51-2804 | 1.8 | 51 | 2.8 | 0.83 | 2.2 | 1.01 | 4 | 300 | 230 | 0.59 |

| LM57HS56-2006 | 1.8 | 56 | 2 | 1.8 | 2.5 | 0.9 | 6 | 350 | 280 | 0.68 |

| LM57HS56-2108 | 1.8 | 56 | 2.1 | 1.8 | 2.5 | 1 | 8 | 350 | 280 | 0.68 |

| LM57HS56-2804 | 1.8 | 56 | 2.8 | 0.9 | 2.5 | 1.2 | 4 | 350 | 280 | 0.68 |

| LM57HS64-2804 | 1.8 | 64 | 2.8 | 0.8 | 2.3 | 1 | 4 | 400 | 300 | 0.75 |

| LM57HS76-2804 | 1.8 | 76 | 2.8 | 1.1 | 3.6 | 1.89 | 4 | 600 | 440 | 1.1 |

| LM57HS76-3006 | 1.8 | 76 | 3 | 1 | 1.6 | 1.35 | 6 | 600 | 440 | 1.1 |

| LM57HS76-3008 | 1.8 | 76 | 3 | 1 | 1.8 | 1.5 | 8 | 600 | 440 | 1.1 |

| LM57HS82-3004 | 1.8 | 82 | 3 | 1.2 | 4 | 2.1 | 4 | 1000 | 600 | 1.2 |

| LM57HS82-4008 | 1.8 | 82 | 4 | 0.8 | 1.8 | 2 | 8 | 1000 | 600 | 1.2 |

| LM57HS82-4204 | 1.8 | 82 | 4.2 | 0.7 | 2.5 | 2.2 | 4 | 1000 | 600 | 1.2 |

| JK57HS100-4204 | 1.8 | 100 | 4.2 | 0.75 | 3 | 3 | 4 | 1100 | 700 | 1.3 |

| LM57HS112-3004 | 1.8 | 112 | 3 | 1.6 | 7.5 | 3 | 4 | 1200 | 800 | 1.4 |

| LM57HS112-4204 | 1.8 | 112 | 4.2 | 0.9 | 3.8 | 3.1 | 4 | 1200 | 800 | 1.4 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM57HY41-0406 | 1.8 | 41 | 0.4 | 30 | 30 | 2.88 | 6 | 180 | 57 | 0.54 |

| LM57HY41-1564 | 1.8 | 41 | 1.56 | 1.8 | 3.6 | 4 | 4 | 180 | 57 | 0.54 |

| LM57HY51-0426 | 1.8 | 51 | 0.42 | 29 | 36 | 4.97 | 6 | 350 | 110 | 0.6 |

| LM57HY51-2804 | 1.8 | 51 | 2.8 | 0.85 | 2.1 | 6.9 | 4 | 350 | 110 | 0.6 |

| LM57HY56-0606 | 1.8 | 56 | 0.6 | 20 | 32 | 6 | 6 | 420 | 135 | 0.65 |

| LM57HY56-2004 | 1.8 | 56 | 2 | 3 | 7 | 8 | 4 | 420 | 135 | 0.65 |

| LM57HY76-1506 | 1.8 | 76 | 1.5 | 3.6 | 6 | 9 | 6 | 720 | 200 | 0.95 |

| LM57HY76-4004 | 1.8 | 76 | 4 | 0.88 | 2.6 | 14 | 4 | 720 | 200 | 0.95 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | g.cm | g.cm2 | Kg | |

| LM57H3P42-5206 | 1.2 | 42 | 5.2 | 1.3 | 1.4 | 4.5 | 210 | 110 | 0.45 |

| LM57H3P56-5606 | 1.2 | 56 | 5.6 | 0.7 | 0.7 | 9 | 400 | 300 | 0.75 |

| LM57H3P79-5206 | 1.2 | 79 | 5.2 | 0.9 | 1.5 | 15 | 680 | 480 | 1.1 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

| Item | Specifications |

| Step Angle | 1.8° or 0.9° or 1.2° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 75N (20mm from the flange) |

| Max. axial force | 15N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM57HM41-1006 | 0.9 | 41 | 1 | 5.7 | 8 | 3.9 | 6 | 210 | 120 | 0.45 |

| LM57HM41-2804 | 0.9 | 41 | 2.8 | 0.7 | 2.2 | 5 | 4 | 210 | 120 | 0.45 |

| LM57HM51-2006 | 0.9 | 51 | 2 | 1.6 | 2.2 | 7.2 | 6 | 380 | 280 | 0.68 |

| LM57HM56-1006 | 0.9 | 56 | 1 | 7.4 | 17.5 | 9 | 6 | 400 | 300 | 0.7 |

| LM57HM56-2006 | 0.9 | 56 | 2 | 1.8 | 4.5 | 9 | 6 | 400 | 300 | 0.7 |

| LM57HM56-2804 | 0.9 | 56 | 2.8 | 0.9 | 3.3 | 12 | 4 | 400 | 300 | 0.7 |

| LM57HM76-1006 | 0.9 | 76 | 1 | 8.6 | 23 | 13.5 | 6 | 680 | 480 | 1 |

| LM57HM76-2006 | 0.9 | 76 | 2 | 3 | 7 | 13.5 | 6 | 680 | 480 | 1 |

| LM57HM76-2804 | 0.9 | 76 | 2.8 | 1.15 | 5.6 | 18 | 4 | 680 | 480 | 1 |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm | g.cm2 | Kg | |

| LM57HS41-1006 | 1.8 | 41 | 1 | 7.1 | 8 | 0.48 | 6 | 250 | 150 | 0.47 |

| LM57HS41-2008 | 1.8 | 41 | 2 | 1.4 | 1.4 | 0.39 | 8 | 250 | 150 | 0.47 |

| LM57HS41-2804 | 1.8 | 41 | 2.8 | 0.7 | 1.4 | 0.55 | 4 | 250 | 150 | 0.47 |

| LM57HS51-1006 | 1.8 | 51 | 1 | 6.6 | 8.2 | 0.72 | 6 | 300 | 230 | 0.59 |

| LM57HS51-2008 | 1.8 | 51 | 2 | 1.8 | 2.7 | 0.9 | 8 | 300 | 230 | 0.59 |

| LM57HS51-2804 | 1.8 | 51 | 2.8 | 0.83 | 2.2 | 1.01 | 4 | 300 | 230 | 0.59 |

| LM57HS56-2006 | 1.8 | 56 | 2 | 1.8 | 2.5 | 0.9 | 6 | 350 | 280 | 0.68 |

| LM57HS56-2108 | 1.8 | 56 | 2.1 | 1.8 | 2.5 | 1 | 8 | 350 | 280 | 0.68 |

| LM57HS56-2804 | 1.8 | 56 | 2.8 | 0.9 | 2.5 | 1.2 | 4 | 350 | 280 | 0.68 |

| LM57HS64-2804 | 1.8 | 64 | 2.8 | 0.8 | 2.3 | 1 | 4 | 400 | 300 | 0.75 |

| LM57HS76-2804 | 1.8 | 76 | 2.8 | 1.1 | 3.6 | 1.89 | 4 | 600 | 440 | 1.1 |

| LM57HS76-3006 | 1.8 | 76 | 3 | 1 | 1.6 | 1.35 | 6 | 600 | 440 | 1.1 |

| LM57HS76-3008 | 1.8 | 76 | 3 | 1 | 1.8 | 1.5 | 8 | 600 | 440 | 1.1 |

| LM57HS82-3004 | 1.8 | 82 | 3 | 1.2 | 4 | 2.1 | 4 | 1000 | 600 | 1.2 |

| LM57HS82-4008 | 1.8 | 82 | 4 | 0.8 | 1.8 | 2 | 8 | 1000 | 600 | 1.2 |

| LM57HS82-4204 | 1.8 | 82 | 4.2 | 0.7 | 2.5 | 2.2 | 4 | 1000 | 600 | 1.2 |

| JK57HS100-4204 | 1.8 | 100 | 4.2 | 0.75 | 3 | 3 | 4 | 1100 | 700 | 1.3 |

| LM57HS112-3004 | 1.8 | 112 | 3 | 1.6 | 7.5 | 3 | 4 | 1200 | 800 | 1.4 |

| LM57HS112-4204 | 1.8 | 112 | 4.2 | 0.9 | 3.8 | 3.1 | 4 | 1200 | 800 | 1.4 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| LM57HY41-0406 | 1.8 | 41 | 0.4 | 30 | 30 | 2.88 | 6 | 180 | 57 | 0.54 |

| LM57HY41-1564 | 1.8 | 41 | 1.56 | 1.8 | 3.6 | 4 | 4 | 180 | 57 | 0.54 |

| LM57HY51-0426 | 1.8 | 51 | 0.42 | 29 | 36 | 4.97 | 6 | 350 | 110 | 0.6 |

| LM57HY51-2804 | 1.8 | 51 | 2.8 | 0.85 | 2.1 | 6.9 | 4 | 350 | 110 | 0.6 |

| LM57HY56-0606 | 1.8 | 56 | 0.6 | 20 | 32 | 6 | 6 | 420 | 135 | 0.65 |

| LM57HY56-2004 | 1.8 | 56 | 2 | 3 | 7 | 8 | 4 | 420 | 135 | 0.65 |

| LM57HY76-1506 | 1.8 | 76 | 1.5 | 3.6 | 6 | 9 | 6 | 720 | 200 | 0.95 |

| LM57HY76-4004 | 1.8 | 76 | 4 | 0.88 | 2.6 | 14 | 4 | 720 | 200 | 0.95 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | g.cm | g.cm2 | Kg | |

| LM57H3P42-5206 | 1.2 | 42 | 5.2 | 1.3 | 1.4 | 4.5 | 210 | 110 | 0.45 |

| LM57H3P56-5606 | 1.2 | 56 | 5.6 | 0.7 | 0.7 | 9 | 400 | 300 | 0.75 |

| LM57H3P79-5206 | 1.2 | 79 | 5.2 | 0.9 | 1.5 | 15 | 680 | 480 | 1.1 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

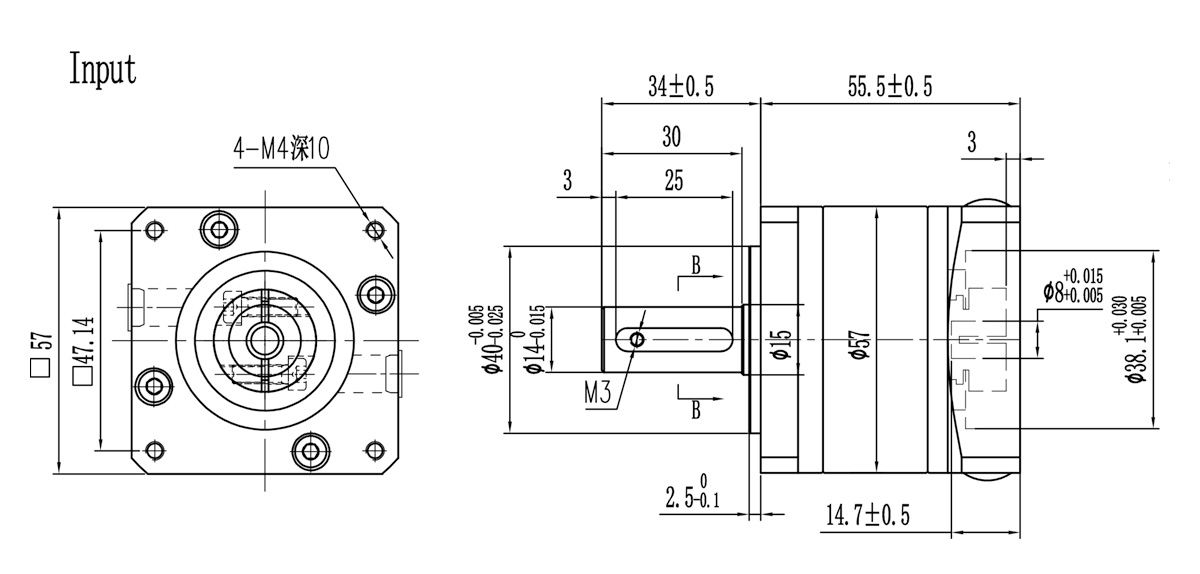

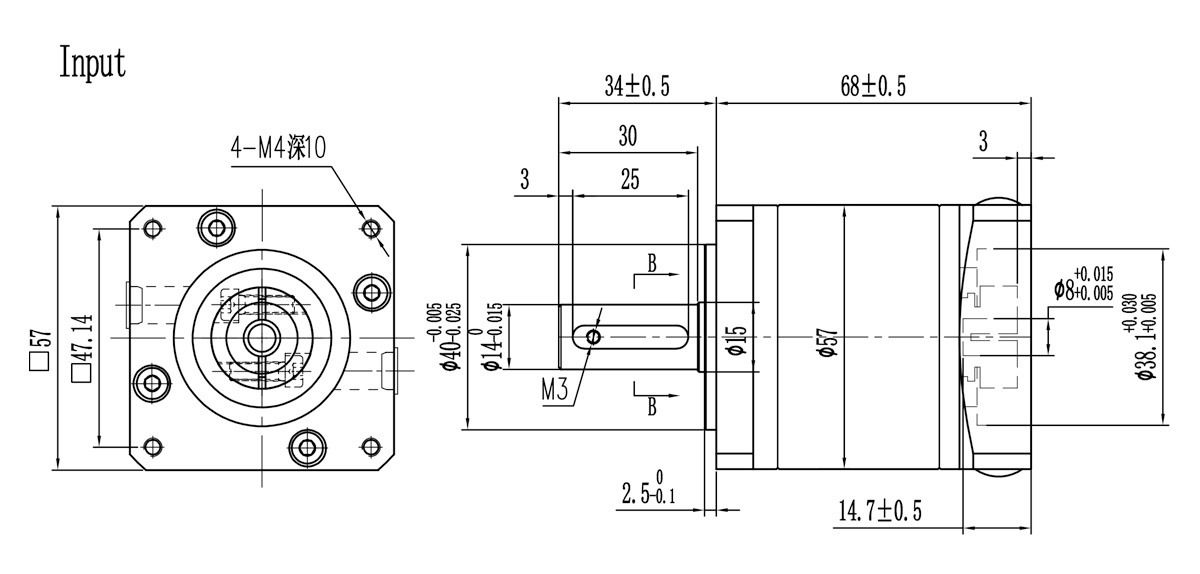

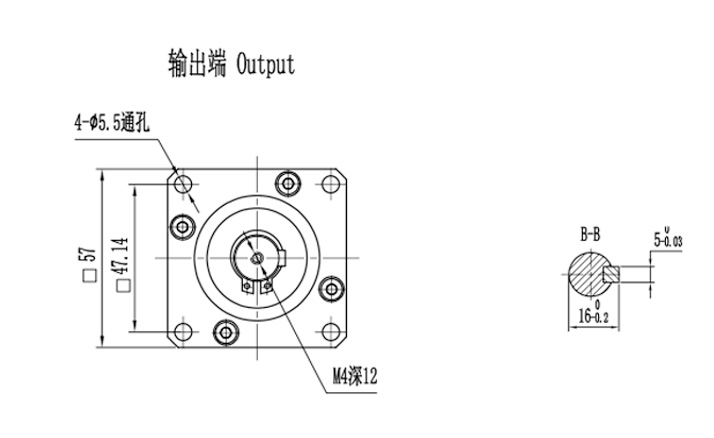

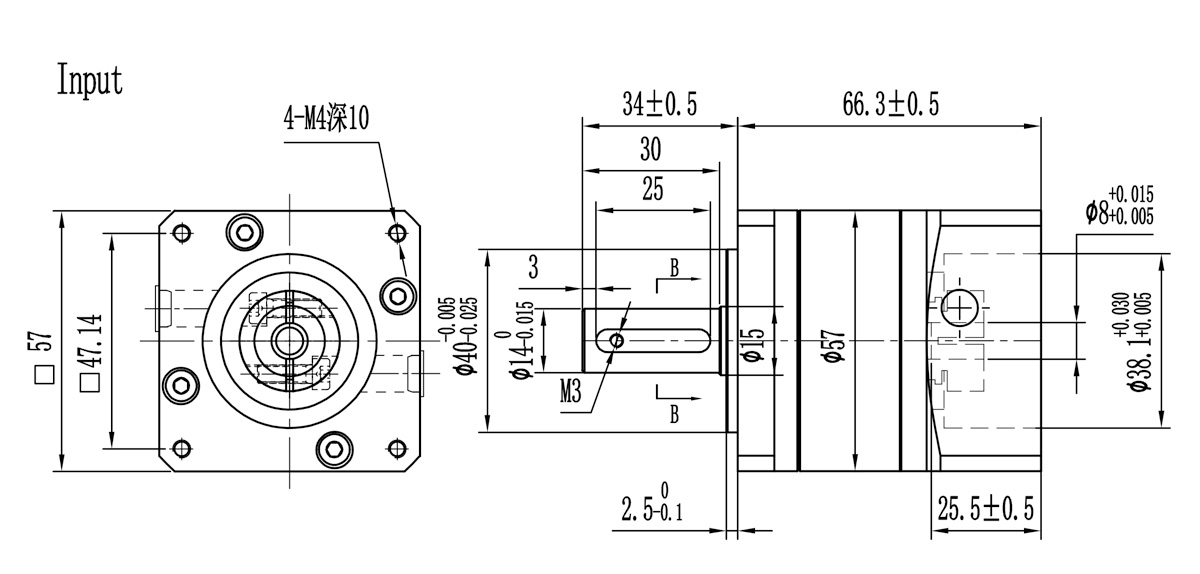

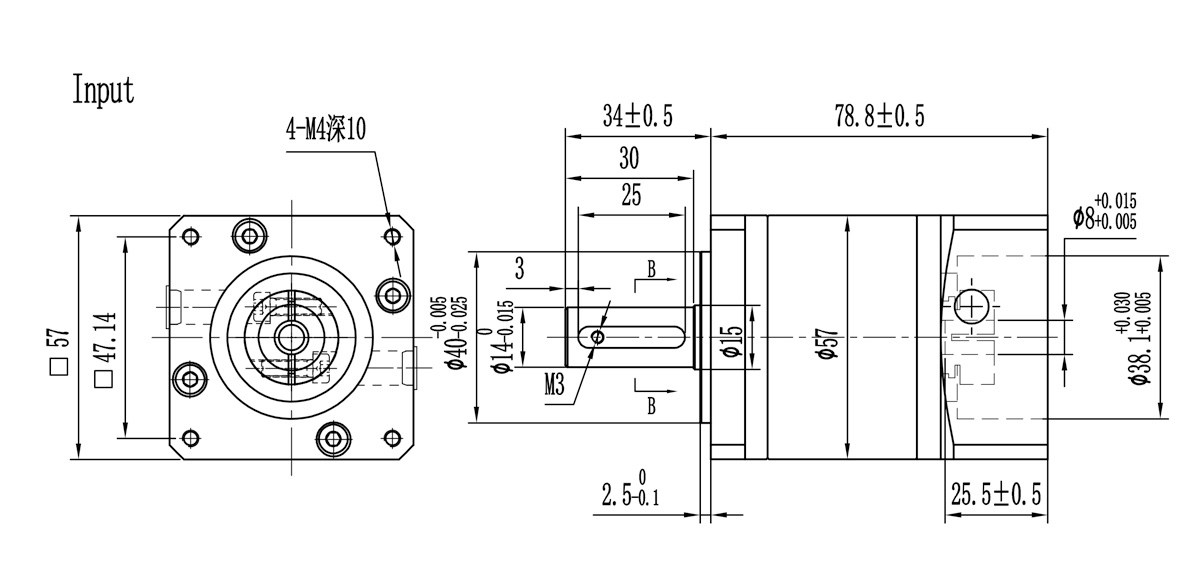

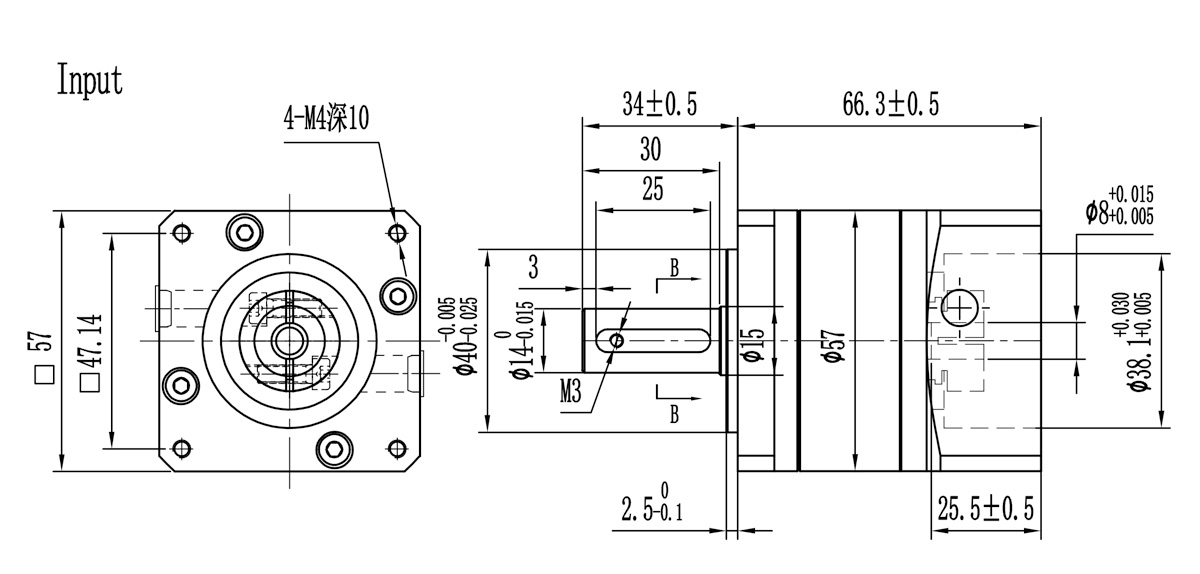

| Model | / | LM-FLF57-L1 | LM-FLF57-L2 | ||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 50 |

| Gear Trains | / | 1 | 2 | ||||

| Gearbox Length | mm | 89.5 | 102 | ||||

| Rated Torque | N.m | 25 | 25 | 10 | 25 | 25 | 20 |

| Sundden Stop Torque | N.m | 50 | 50 | 20 | 50 | 50 | 40 |

| Back Lash | arcmin | ≤30 arcmin | ≤45 arcmin | ||||

| Efficiency | % | 90 | 80 | ||||

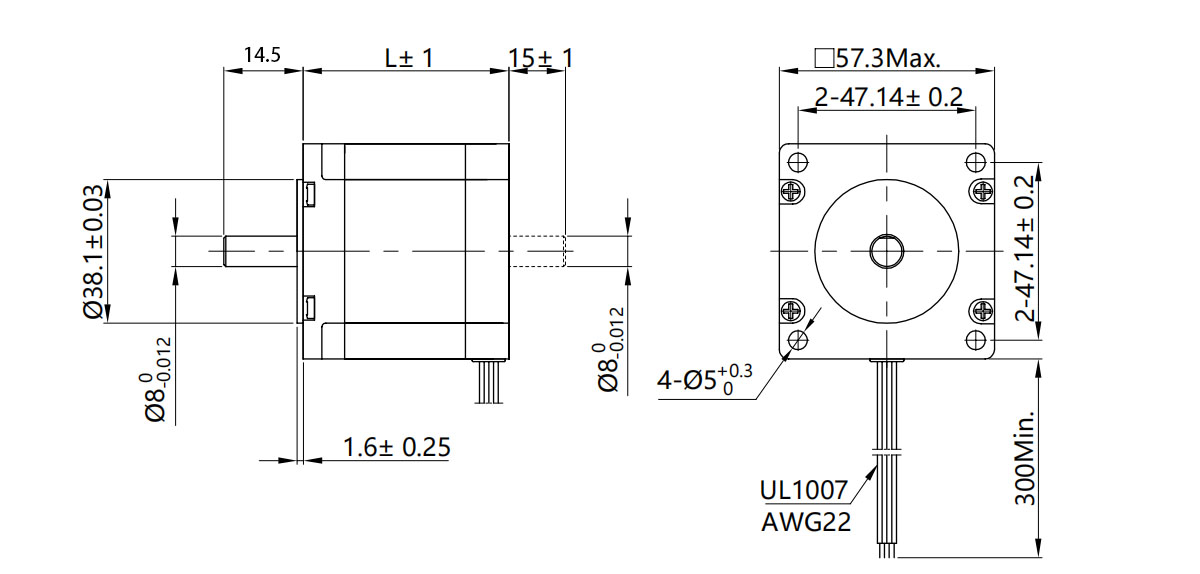

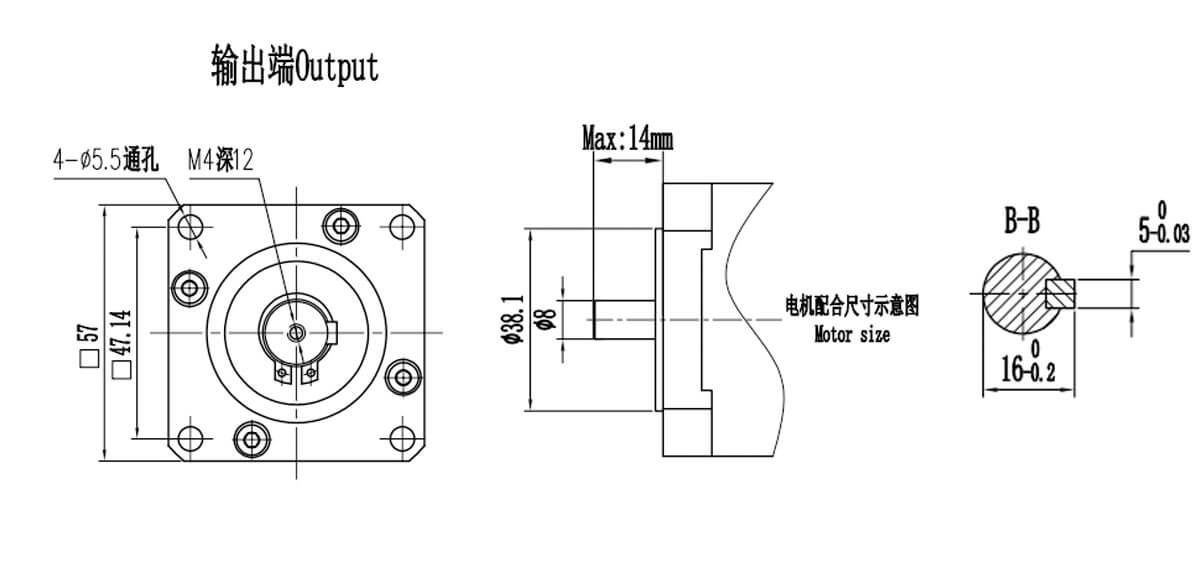

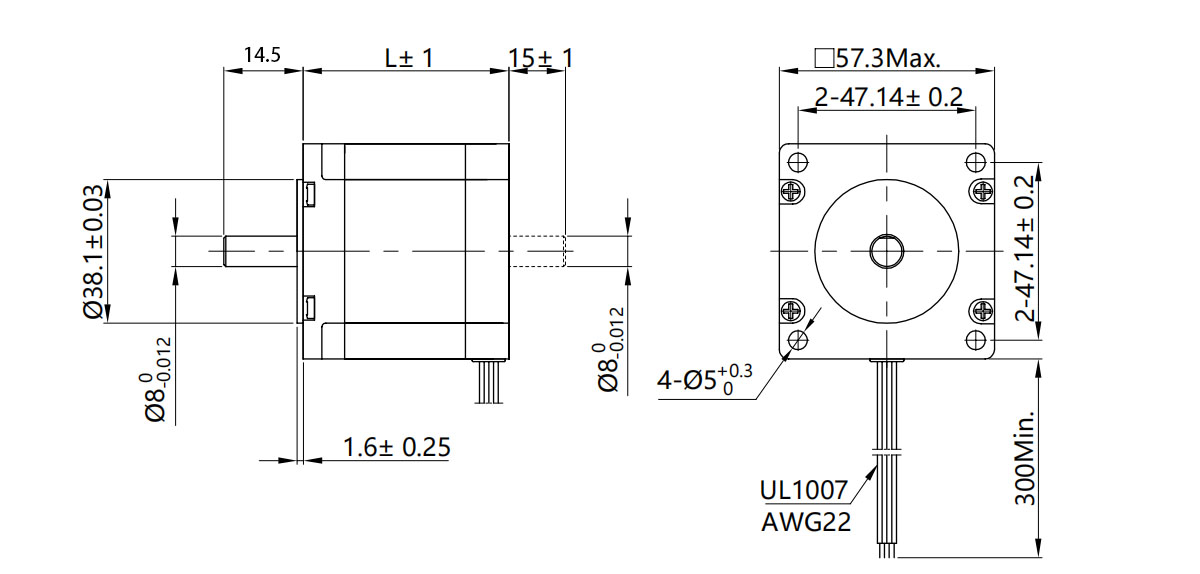

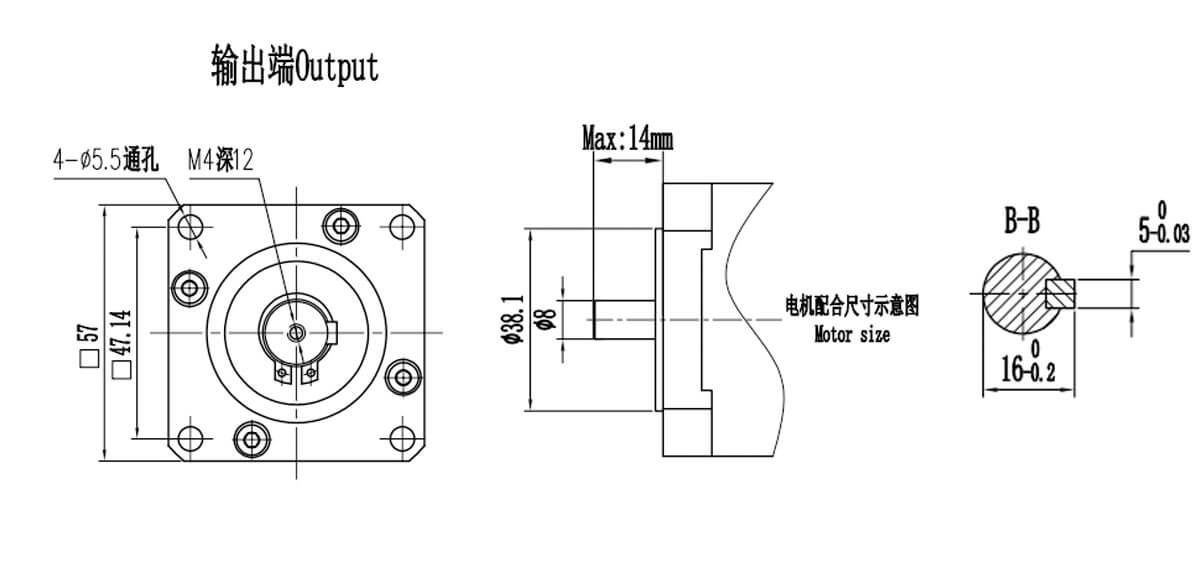

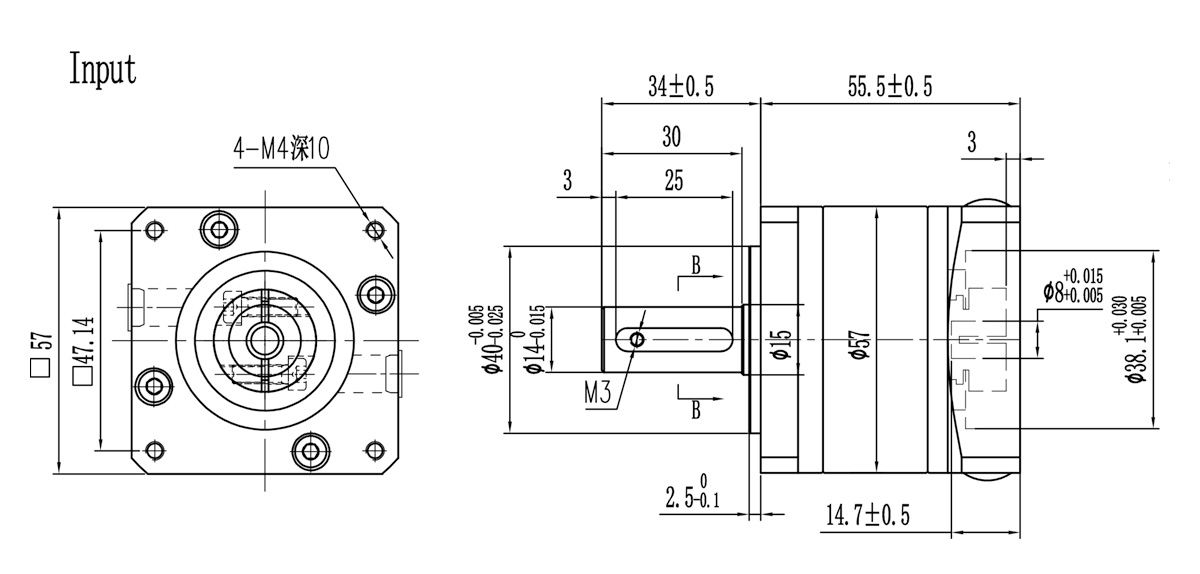

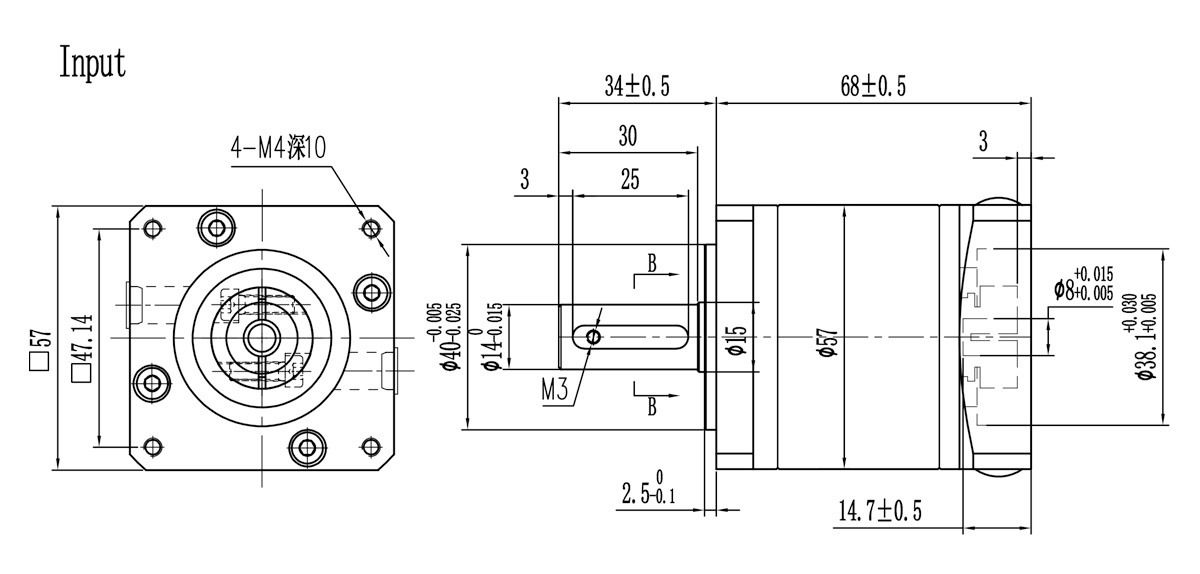

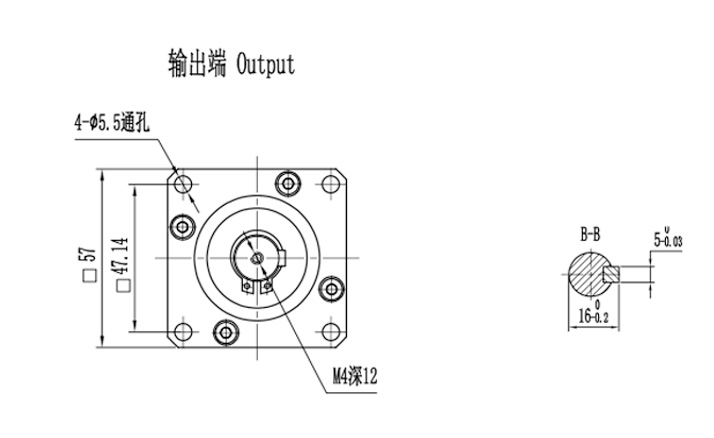

| Suitable Motor Dimension | mm | Φ8-14 / Φ38.1-2 / F47.4-M4 or Φ6.35-14 / Φ38.1-2 / F47.4-M4 | Φ8-14 / Φ38.1-2 / F47.4-M4 or Φ6.35-14 / Φ38.1-2 / F47.4-M4 | ||||

| Rated Input Speed | Rpm | 1000 | 1000 | ||||

| Max Input Speed | Rpm | 2000 | 2000 | ||||

| Average Life Span | h | 20000 | 20000 | ||||

| Axial Force | N | 100 | 200 | ||||

| Radial Force | N | 300 | 400 | ||||

| Noise | dB | ≤55 | ≤55 | ||||

| Protection Level | IP | IP54 | IP54 | ||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | ||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | ||||

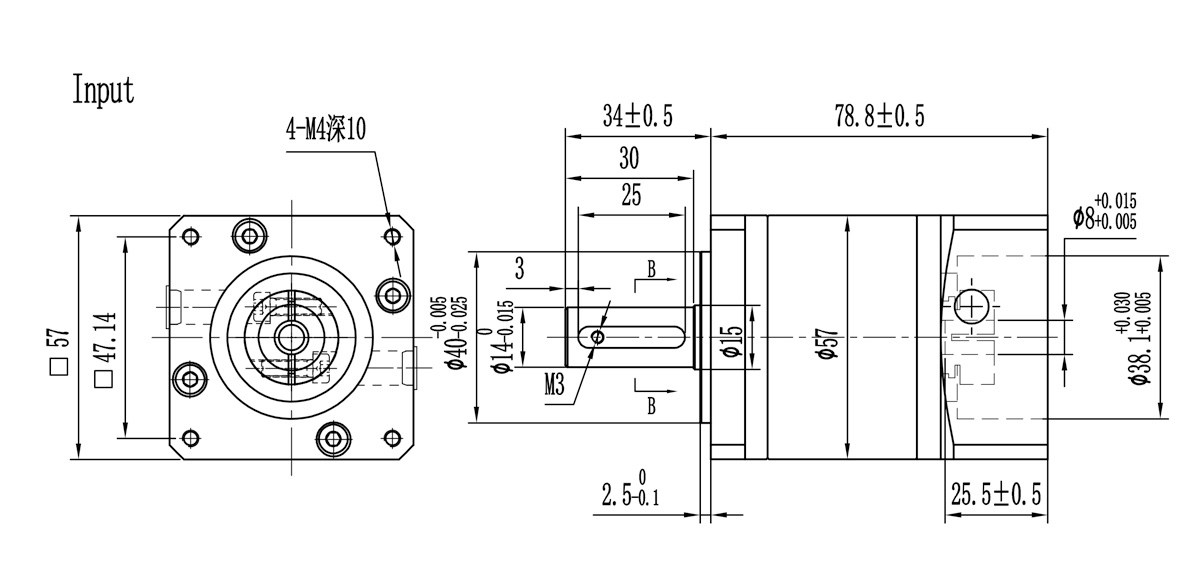

| Model | / | JK-FLF57-L1SW | JK-FLF57-L2SW | ||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 20 |

| Gear Trains | / | 1 | 2 | ||||

| Gearbox Length | mm | 100.3 | 112.8 | ||||

| Rated Torque | N.m | 25 | 25 | 10 | 25 | 25 | 20 |

| Sundden Stop Torque | N.m | 50 | 50 | 20 | 50 | 50 | 40 |

| Back Lash | arcmin | ≤30 arcmin | ≤45 arcmin | ||||

| Efficiency | % | 90 | 80 | ||||

| Suitable Motor Dimension | mm | Φ8-22 / Φ38.1-2 / F47.14-M4 or Φ6.35-22 / Φ38.1-2 / F47.14-M4 | Φ8-22 / Φ38.1-2 / F47.14-M4 or Φ6.35-22 / Φ38.1-2 / F47.14-M4 | ||||

| Rated Input Speed | Rpm | 1000 | 1000 | ||||

| Max Input Speed | Rpm | 2000 | 2000 | ||||

| Average Life Span | h | 20000 | 20000 | ||||

| Axial Force | N | 100 | 100 | ||||

| Radial Force | N | 300 | 300 | ||||

| Noise | dB | ≤55 | ≤55 | ||||

| Protection Level | IP | IP54 | IP54 | ||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | ||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | ||||

| Model | / | LM-FLF57-L1 | LM-FLF57-L2 | ||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 50 |

| Gear Trains | / | 1 | 2 | ||||

| Gearbox Length | mm | 89.5 | 102 | ||||

| Rated Torque | N.m | 25 | 25 | 10 | 25 | 25 | 20 |

| Sundden Stop Torque | N.m | 50 | 50 | 20 | 50 | 50 | 40 |

| Back Lash | arcmin | ≤30 arcmin | ≤45 arcmin | ||||

| Efficiency | % | 90 | 80 | ||||

| Suitable Motor Dimension | mm | Φ8-14 / Φ38.1-2 / F47.4-M4 or Φ6.35-14 / Φ38.1-2 / F47.4-M4 | Φ8-14 / Φ38.1-2 / F47.4-M4 or Φ6.35-14 / Φ38.1-2 / F47.4-M4 | ||||

| Rated Input Speed | Rpm | 1000 | 1000 | ||||

| Max Input Speed | Rpm | 2000 | 2000 | ||||

| Average Life Span | h | 20000 | 20000 | ||||

| Axial Force | N | 100 | 200 | ||||

| Radial Force | N | 300 | 400 | ||||

| Noise | dB | ≤55 | ≤55 | ||||

| Protection Level | IP | IP54 | IP54 | ||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | ||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | ||||

| Model | / | JK-FLF57-L1SW | JK-FLF57-L2SW | ||||

| Gear Ratio | / | 4 | 5 | 10 | 20 | 25 | 20 |

| Gear Trains | / | 1 | 2 | ||||

| Gearbox Length | mm | 100.3 | 112.8 | ||||

| Rated Torque | N.m | 25 | 25 | 10 | 25 | 25 | 20 |

| Sundden Stop Torque | N.m | 50 | 50 | 20 | 50 | 50 | 40 |

| Back Lash | arcmin | ≤30 arcmin | ≤45 arcmin | ||||

| Efficiency | % | 90 | 80 | ||||

| Suitable Motor Dimension | mm | Φ8-22 / Φ38.1-2 / F47.14-M4 or Φ6.35-22 / Φ38.1-2 / F47.14-M4 | Φ8-22 / Φ38.1-2 / F47.14-M4 or Φ6.35-22 / Φ38.1-2 / F47.14-M4 | ||||

| Rated Input Speed | Rpm | 1000 | 1000 | ||||

| Max Input Speed | Rpm | 2000 | 2000 | ||||

| Average Life Span | h | 20000 | 20000 | ||||

| Axial Force | N | 100 | 100 | ||||

| Radial Force | N | 300 | 300 | ||||

| Noise | dB | ≤55 | ≤55 | ||||

| Protection Level | IP | IP54 | IP54 | ||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | ||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | ||||

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

A NEMA 23 planetary geared stepper motor combines a 57 mm stepper motor with a planetary gearbox to increase torque, improve positioning accuracy, and reduce output speed.

Planetary gearboxes provide high torque density, compact structure, low backlash, high efficiency, and smooth motion.

Output torque depends on motor length and gearbox ratio, making it suitable for medium to high-load applications.

Common planetary gearbox ratios range from low to high reductions, depending on speed and torque requirements.

The gearbox reduces speed and increases effective resolution, allowing finer motion control and higher positioning accuracy.

Yes, it is designed for continuous industrial operation when properly driven and cooled.

The standard step angle is 1.8° per step, and microstepping further enhances resolution.

Typical applications include CNC machines, robotics, automation equipment, packaging machinery, and precision positioning systems.

Planetary gearboxes offer higher efficiency, smoother operation, and lower backlash than spur gear designs.

Yes, for medium-speed, high-torque applications, it can be a cost-effective alternative to servo motors.

Yes, motor torque, current, voltage, gearbox ratio, and motor length can be customized.

Yes, a wide range of reduction ratios can be selected to match specific speed and torque requirements.

Yes, incremental or absolute encoders can be integrated to create closed-loop stepper systems.

Yes, compatible stepper drivers can be provided for optimized performance.

Yes, high-precision planetary gearboxes with reduced backlash are available for demanding applications.

Yes, IP-rated housings, corrosion-resistant coatings, and high-temperature insulation can be applied.

Options include round shafts, D-shafts, keyed shafts, or custom-machined shafts.

Testing includes torque verification, backlash measurement, step accuracy testing, thermal testing, and endurance testing.

Prototype lead time is typically 2–4 weeks, with mass production taking 4–8 weeks.

Customization ensures optimal matching between motor, gearbox, and load, resulting in higher efficiency, accuracy, reliability, and service life.

A NEMA 23 planetary geared stepper motor combines a 57 mm stepper motor with a planetary gearbox to increase torque, improve positioning accuracy, and reduce output speed.

Planetary gearboxes provide high torque density, compact structure, low backlash, high efficiency, and smooth motion.

Output torque depends on motor length and gearbox ratio, making it suitable for medium to high-load applications.

Common planetary gearbox ratios range from low to high reductions, depending on speed and torque requirements.

The gearbox reduces speed and increases effective resolution, allowing finer motion control and higher positioning accuracy.

Yes, it is designed for continuous industrial operation when properly driven and cooled.

The standard step angle is 1.8° per step, and microstepping further enhances resolution.

Typical applications include CNC machines, robotics, automation equipment, packaging machinery, and precision positioning systems.

Planetary gearboxes offer higher efficiency, smoother operation, and lower backlash than spur gear designs.

Yes, for medium-speed, high-torque applications, it can be a cost-effective alternative to servo motors.

Yes, motor torque, current, voltage, gearbox ratio, and motor length can be customized.

Yes, a wide range of reduction ratios can be selected to match specific speed and torque requirements.

Yes, incremental or absolute encoders can be integrated to create closed-loop stepper systems.

Yes, compatible stepper drivers can be provided for optimized performance.

Yes, high-precision planetary gearboxes with reduced backlash are available for demanding applications.

Yes, IP-rated housings, corrosion-resistant coatings, and high-temperature insulation can be applied.

Options include round shafts, D-shafts, keyed shafts, or custom-machined shafts.

Testing includes torque verification, backlash measurement, step accuracy testing, thermal testing, and endurance testing.

Prototype lead time is typically 2–4 weeks, with mass production taking 4–8 weeks.

Customization ensures optimal matching between motor, gearbox, and load, resulting in higher efficiency, accuracy, reliability, and service life.