- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

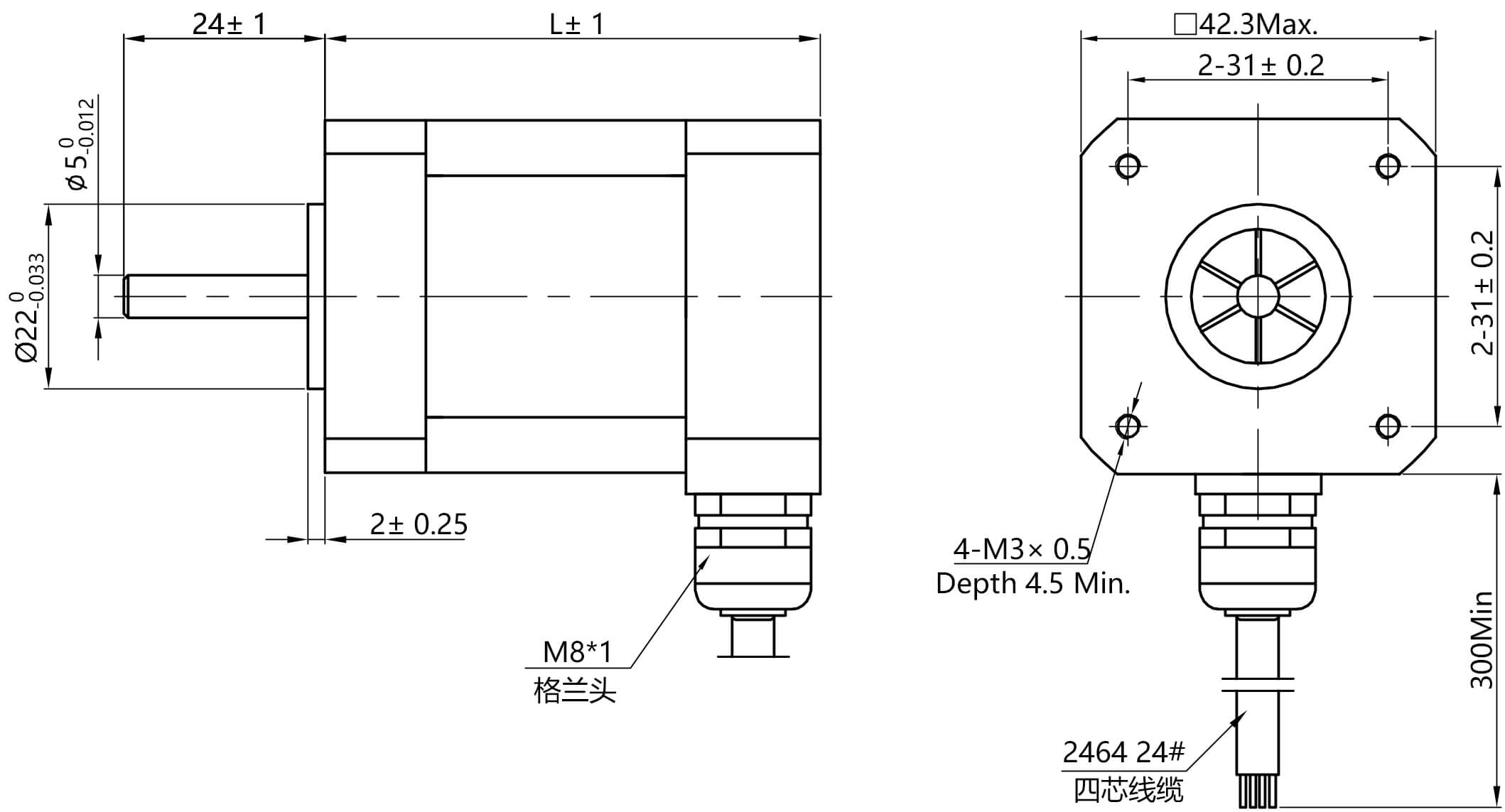

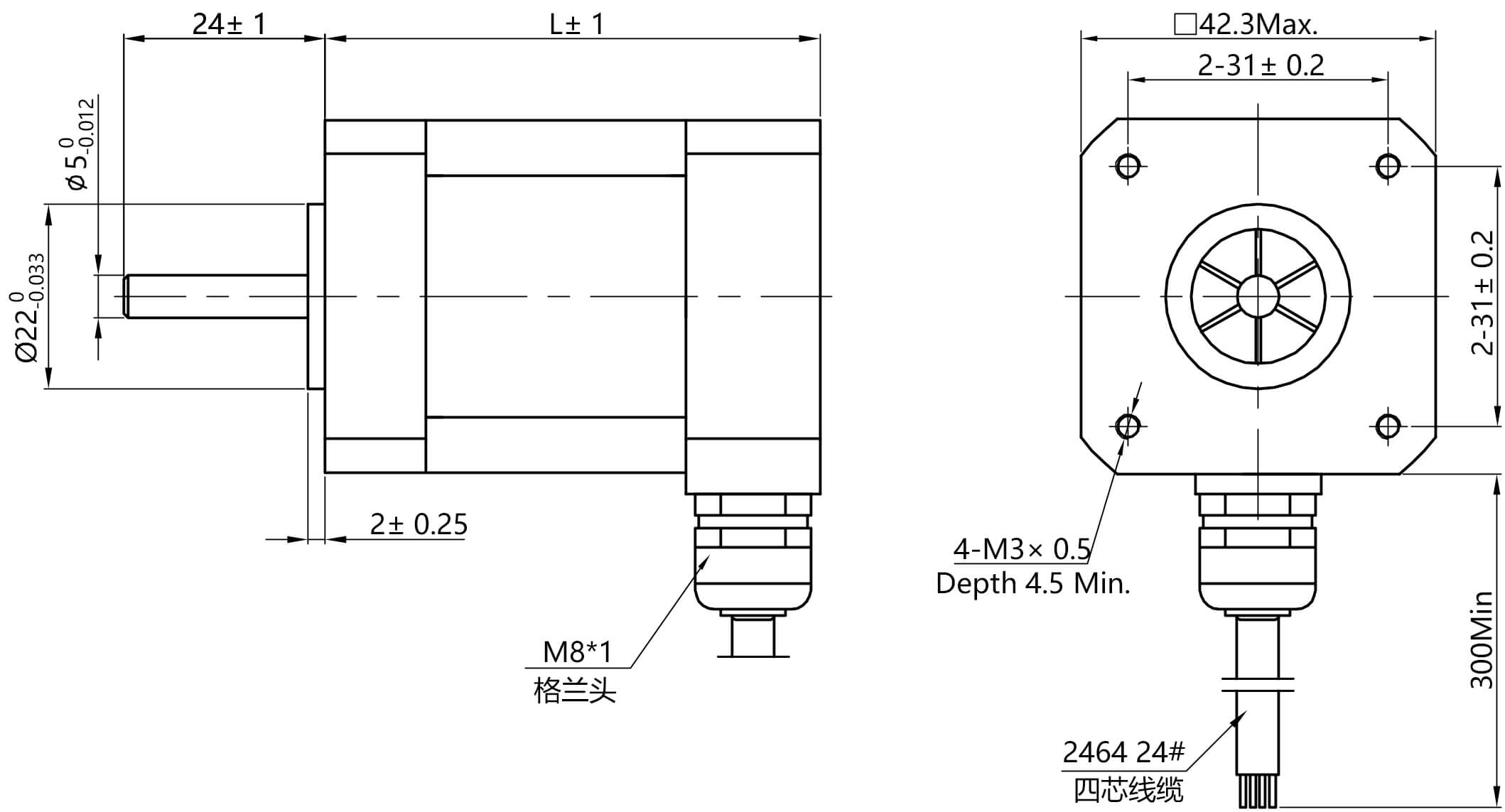

Motor Length: 34mm / 40mm / 48mm /60mm

| Availability: | |

|---|---|

| Quantity: | |

Nema 17 Waterproof Stepper Motor

LEANMOTOR

Waterproof Motors

Nema17 (42mm)

4wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm² | kg | |

| LM42HSW34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 34 | 0.22 |

| LM42HSW40-1704 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 54 | 0.28 |

| LM42HSW48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 5.5 | 4 | 68 | 0.38 |

| LM42HSW60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 102 | 0.55 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm² | kg | |

| LM42HSW34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 34 | 0.22 |

| LM42HSW40-1704 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 54 | 0.28 |

| LM42HSW48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 5.5 | 4 | 68 | 0.38 |

| LM42HSW60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 102 | 0.55 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

A NEMA 17 waterproof stepping motor is a compact, high-precision stepper motor with IP-rated sealing to protect against dust and water, ideal for harsh or outdoor environments.

Waterproof stepper motors provide reliable operation in wet, dusty, or humid conditions while maintaining precision, torque, and longevity.

Applications include medical equipment, 3D printers, automation, robotics, packaging, and outdoor machinery where moisture resistance is critical.

Standard NEMA 17 motors usually have a 1.8° step angle, providing 200 steps per revolution for high-precision control.

Torque depends on winding and current ratings, typically ranging from 30–60 N·cm for compact models, enough for precise low- to medium-load applications.

Yes, these motors are designed for continuous operation when used within their rated voltage, current, and torque limits.

Depending on the IP rating (e.g., IP54, IP65), it can resist splashes, dust, and light immersion, ensuring reliability in demanding environments.

They work with standard stepper drivers, microstepping controllers, and motion controllers for smooth and precise positioning.

Yes, their robust construction and precision winding enable smooth, accurate low-speed operation with minimal vibration.

They feature a small 42mm × 42mm frame, making them suitable for space-constrained applications while maintaining performance.

Yes, winding, current rating, and voltage can be adjusted to meet precise torque and speed needs.

Yes, options such as IP54, IP65, or higher can be provided depending on environmental protection requirements.

Yes, shaft diameter, length, shape (round, flat, D-shaped), and coatings can be tailored for specific applications.

Yes, manufacturers can modify step angles or optimize for microstepping to achieve higher positional accuracy.

Yes, precision windings, quality bearings, and optimized drivers reduce noise and vibration for sensitive applications.

Yes, incremental or absolute encoders can be added for feedback-based control and higher system accuracy.

Yes, materials and coatings can be selected for corrosion resistance, strength, or heat dissipation requirements.

Yes, full OEM/ODM services are available, including custom labeling, motor design, and integration with client systems.

Prototype development usually takes 2–3 weeks, while mass production ranges from 4–8 weeks depending on complexity.

Customizing torque, shaft, IP rating, step resolution, and optional sensors ensures optimal integration, efficiency, and reliability in specific applications.

A NEMA 17 waterproof stepping motor is a compact, high-precision stepper motor with IP-rated sealing to protect against dust and water, ideal for harsh or outdoor environments.

Waterproof stepper motors provide reliable operation in wet, dusty, or humid conditions while maintaining precision, torque, and longevity.

Applications include medical equipment, 3D printers, automation, robotics, packaging, and outdoor machinery where moisture resistance is critical.

Standard NEMA 17 motors usually have a 1.8° step angle, providing 200 steps per revolution for high-precision control.

Torque depends on winding and current ratings, typically ranging from 30–60 N·cm for compact models, enough for precise low- to medium-load applications.

Yes, these motors are designed for continuous operation when used within their rated voltage, current, and torque limits.

Depending on the IP rating (e.g., IP54, IP65), it can resist splashes, dust, and light immersion, ensuring reliability in demanding environments.

They work with standard stepper drivers, microstepping controllers, and motion controllers for smooth and precise positioning.

Yes, their robust construction and precision winding enable smooth, accurate low-speed operation with minimal vibration.

They feature a small 42mm × 42mm frame, making them suitable for space-constrained applications while maintaining performance.

Yes, winding, current rating, and voltage can be adjusted to meet precise torque and speed needs.

Yes, options such as IP54, IP65, or higher can be provided depending on environmental protection requirements.

Yes, shaft diameter, length, shape (round, flat, D-shaped), and coatings can be tailored for specific applications.

Yes, manufacturers can modify step angles or optimize for microstepping to achieve higher positional accuracy.

Yes, precision windings, quality bearings, and optimized drivers reduce noise and vibration for sensitive applications.

Yes, incremental or absolute encoders can be added for feedback-based control and higher system accuracy.

Yes, materials and coatings can be selected for corrosion resistance, strength, or heat dissipation requirements.

Yes, full OEM/ODM services are available, including custom labeling, motor design, and integration with client systems.

Prototype development usually takes 2–3 weeks, while mass production ranges from 4–8 weeks depending on complexity.

Customizing torque, shaft, IP rating, step resolution, and optional sensors ensures optimal integration, efficiency, and reliability in specific applications.