- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 0.67A / 0.95A

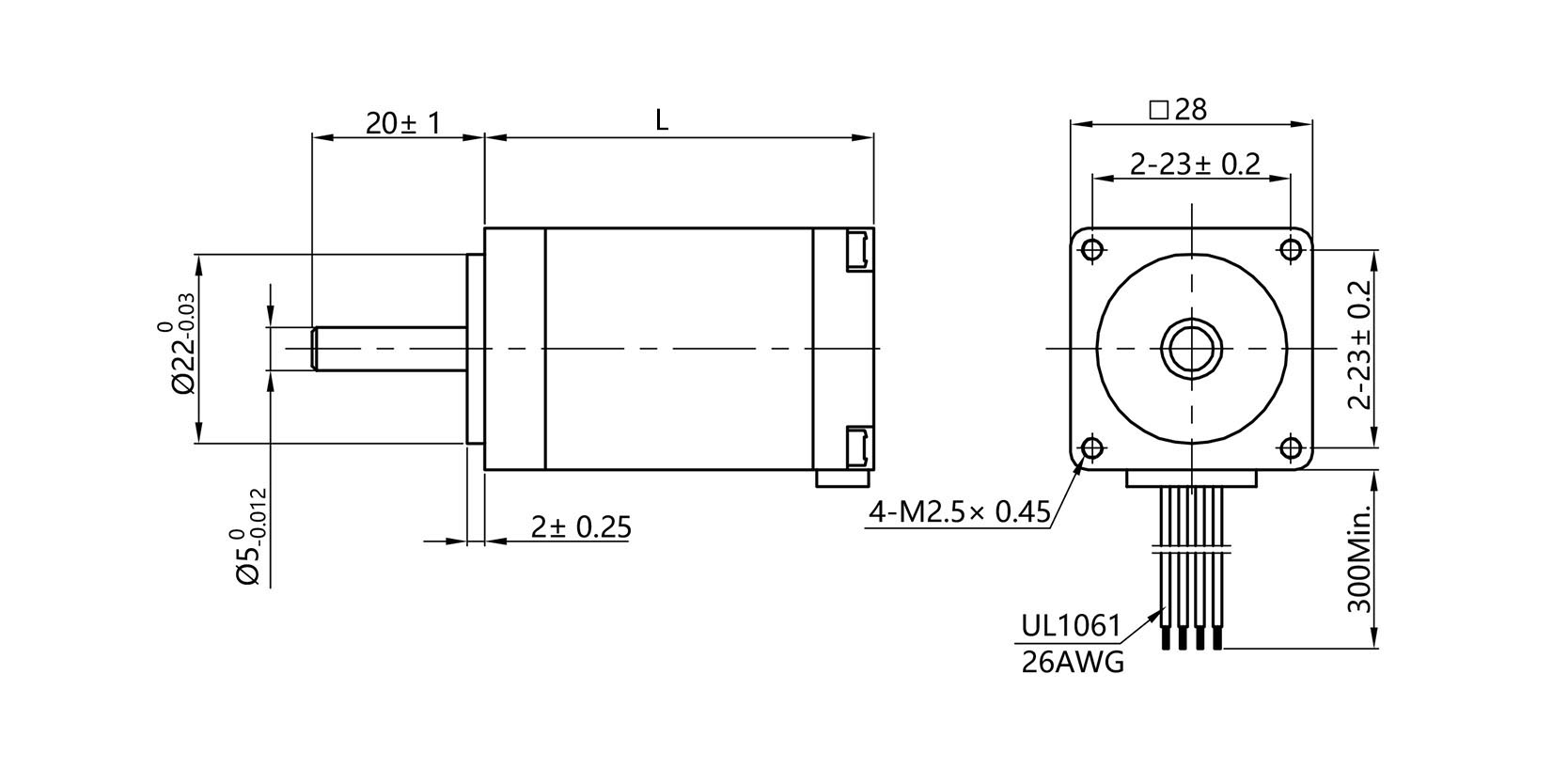

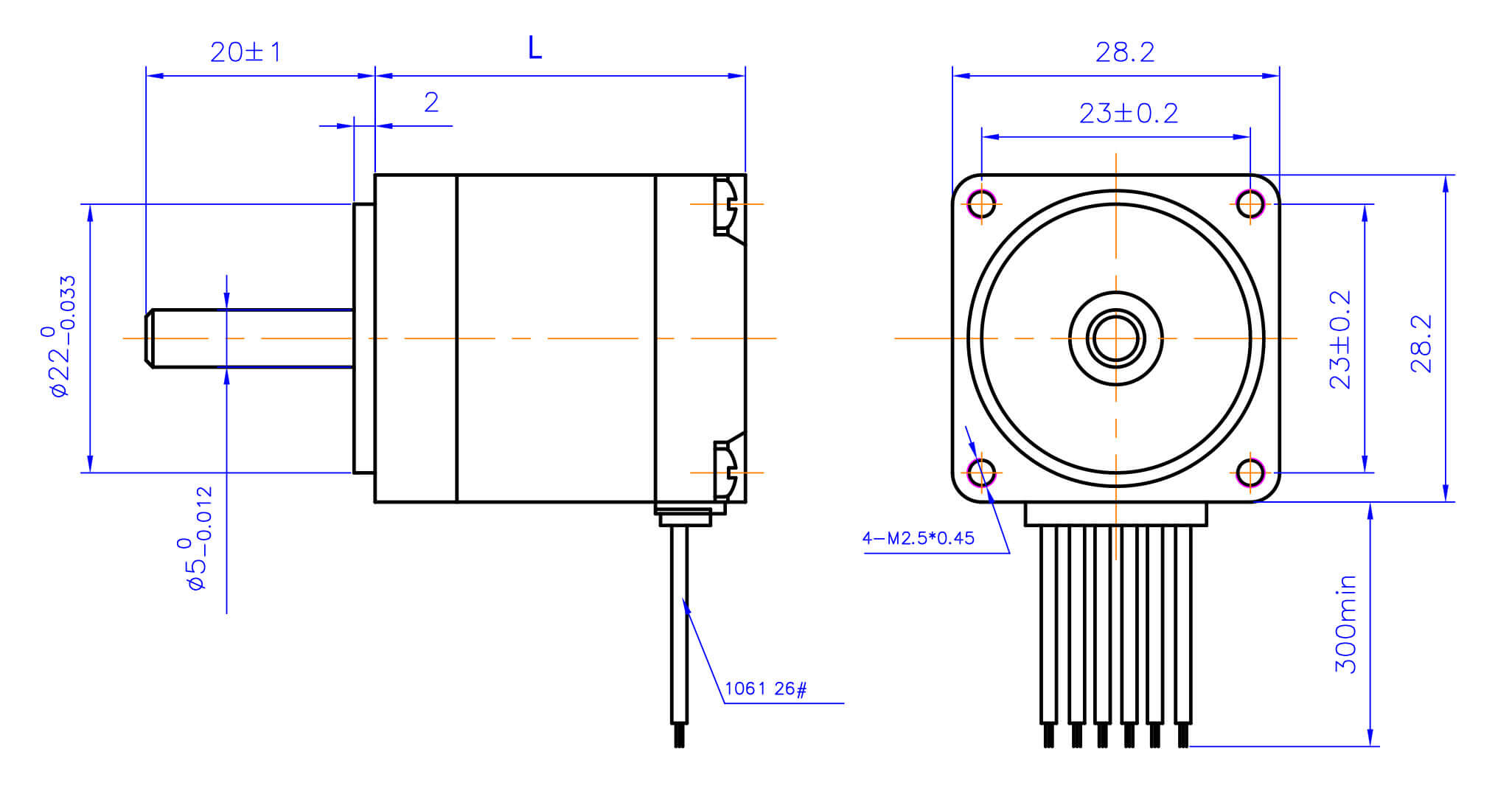

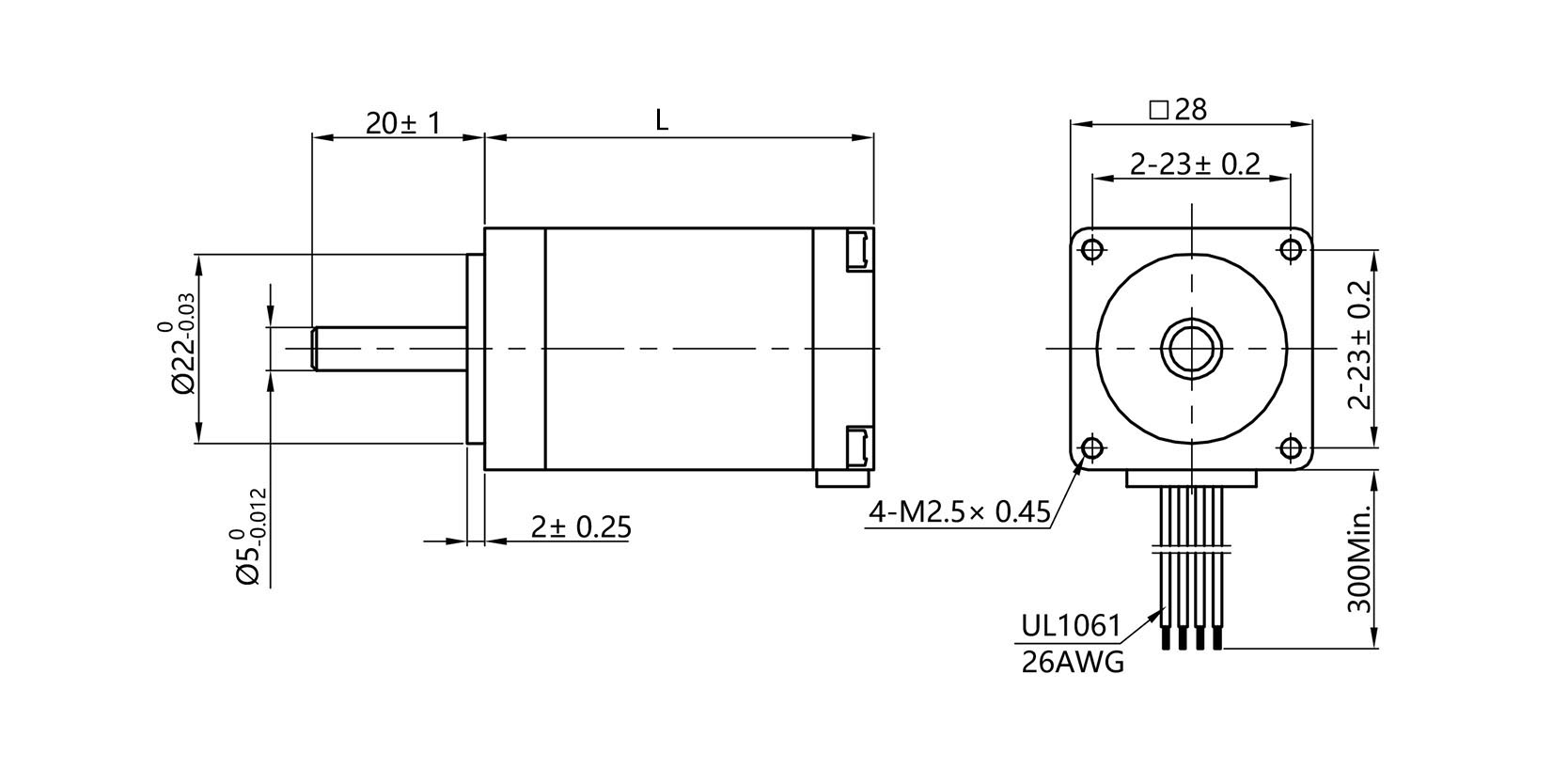

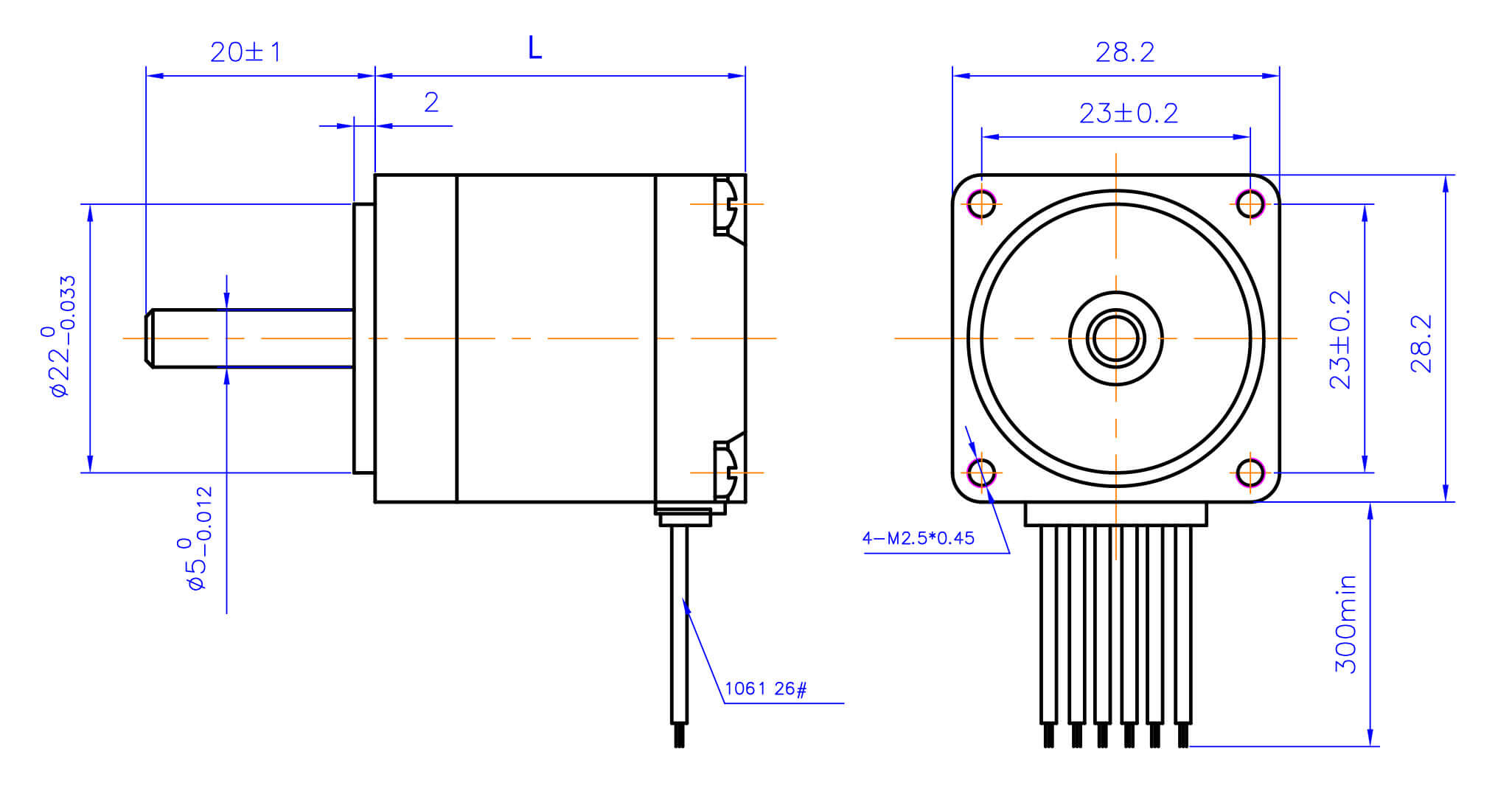

Motor Length: 32mm / 45mm / 51mm

| Availability: | |

|---|---|

| Quantity: | |

Nema 11 Stepper Motor

LeanMotor

Open Loop Motors

Nema11 (28mm)

4wires, 6wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm2 | Kg | |

| LM28HS32-0674 | 1.8 | 32 | 0.67 | 5.6 | 3.4 | 600 | 4 | 9 | 0.11 |

| LM28HS32-0956 | 1.8 | 32 | 0.95 | 2.8 | 0.8 | 430 | 6 | 9 | 0.11 |

| LM28HS45-0956 | 1.8 | 45 | 0.95 | 3.4 | 1.2 | 750 | 6 | 12 | 0.14 |

| LM28HS45-0674 | 1.8 | 45 | 0.67 | 6.8 | 4.9 | 950 | 4 | 12 | 0.14 |

| LM28HS51-0956 | 1.8 | 51 | 0.95 | 4.6 | 1.8 | 900 | 6 | 18 | 0.2 |

| LM28HS51-0674 | 1.8 | 51 | 0.67 | 9.2 | 7.2 | 1200 | 4 | 18 | 0.2 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm2 | Kg | |

| LM28HS32-0674 | 1.8 | 32 | 0.67 | 5.6 | 3.4 | 600 | 4 | 9 | 0.11 |

| LM28HS32-0956 | 1.8 | 32 | 0.95 | 2.8 | 0.8 | 430 | 6 | 9 | 0.11 |

| LM28HS45-0956 | 1.8 | 45 | 0.95 | 3.4 | 1.2 | 750 | 6 | 12 | 0.14 |

| LM28HS45-0674 | 1.8 | 45 | 0.67 | 6.8 | 4.9 | 950 | 4 | 12 | 0.14 |

| LM28HS51-0956 | 1.8 | 51 | 0.95 | 4.6 | 1.8 | 900 | 6 | 18 | 0.2 |

| LM28HS51-0674 | 1.8 | 51 | 0.67 | 9.2 | 7.2 | 1200 | 4 | 18 | 0.2 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| A+ | O+ | A- | B+ | O- | B- |

| Black | Yellow | Green | Red | White | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

A NEMA 11 hybrid stepping motor is a compact stepper motor with a 1.1-inch (28 mm) frame size, designed for precise positioning in space-limited applications.

Key advantages include small size, high positioning accuracy, stable torque output, low power consumption, and simple control.

Most NEMA 11 hybrid stepping motors feature a standard step angle of 1.8°, offering 200 steps per revolution.

Yes, especially when used with microstepping drivers, it provides smooth and accurate motion.

Torque output varies by model and motor length, making it suitable for light-load and precision-driven applications.

Yes, they are suitable for continuous-duty operation when properly driven and adequately cooled.

They are typically used with low-voltage, current-controlled stepper drivers; exact ratings depend on winding design.

Typical applications include medical devices, laboratory instruments, office automation, optical equipment, and compact robotics.

Yes, microstepping and optimized drivers significantly improve smoothness at low speeds.

With a brushless design and simple mechanical structure, NEMA 11 hybrid stepping motors offer long service life and high reliability.

Yes, factories can customize torque, winding parameters, motor length, and electrical specifications.

Yes, options include round shafts, D-shafts, single or double shafts, and custom shaft designs.

Yes, NEMA 11 hybrid stepping motors can be combined with planetary gearboxes for higher torque output.

Yes, encoders can be added to create closed-loop stepper motor configurations.

Yes, optimized electromagnetic design and precision components help reduce noise and vibration.

Manufacturers can provide customized IP-rated designs for harsh or specialized environments.

Testing includes torque testing, step accuracy testing, insulation resistance testing, thermal testing, and endurance testing.

Yes, motor length, housing materials, and internal structure can be optimized for minimal space usage.

Prototype samples typically take 2–4 weeks, while mass production usually requires 4–8 weeks.

Customization ensures the motor is precisely matched to the application, improving efficiency, accuracy, and long-term reliability.

A NEMA 11 hybrid stepping motor is a compact stepper motor with a 1.1-inch (28 mm) frame size, designed for precise positioning in space-limited applications.

Key advantages include small size, high positioning accuracy, stable torque output, low power consumption, and simple control.

Most NEMA 11 hybrid stepping motors feature a standard step angle of 1.8°, offering 200 steps per revolution.

Yes, especially when used with microstepping drivers, it provides smooth and accurate motion.

Torque output varies by model and motor length, making it suitable for light-load and precision-driven applications.

Yes, they are suitable for continuous-duty operation when properly driven and adequately cooled.

They are typically used with low-voltage, current-controlled stepper drivers; exact ratings depend on winding design.

Typical applications include medical devices, laboratory instruments, office automation, optical equipment, and compact robotics.

Yes, microstepping and optimized drivers significantly improve smoothness at low speeds.

With a brushless design and simple mechanical structure, NEMA 11 hybrid stepping motors offer long service life and high reliability.

Yes, factories can customize torque, winding parameters, motor length, and electrical specifications.

Yes, options include round shafts, D-shafts, single or double shafts, and custom shaft designs.

Yes, NEMA 11 hybrid stepping motors can be combined with planetary gearboxes for higher torque output.

Yes, encoders can be added to create closed-loop stepper motor configurations.

Yes, optimized electromagnetic design and precision components help reduce noise and vibration.

Manufacturers can provide customized IP-rated designs for harsh or specialized environments.

Testing includes torque testing, step accuracy testing, insulation resistance testing, thermal testing, and endurance testing.

Yes, motor length, housing materials, and internal structure can be optimized for minimal space usage.

Prototype samples typically take 2–4 weeks, while mass production usually requires 4–8 weeks.

Customization ensures the motor is precisely matched to the application, improving efficiency, accuracy, and long-term reliability.