- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Current: 0.67A

Resistance: 5.6/6.8/9.2Ω

Rated Torque: 600/950/1200g.cm

| Availability: | |

|---|---|

| Quantity: | |

Nema 11 Hybrid Close Loop Stepper Motor

LeanMotor

Closed Loop Motors

Nema11 (28mm)

4wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

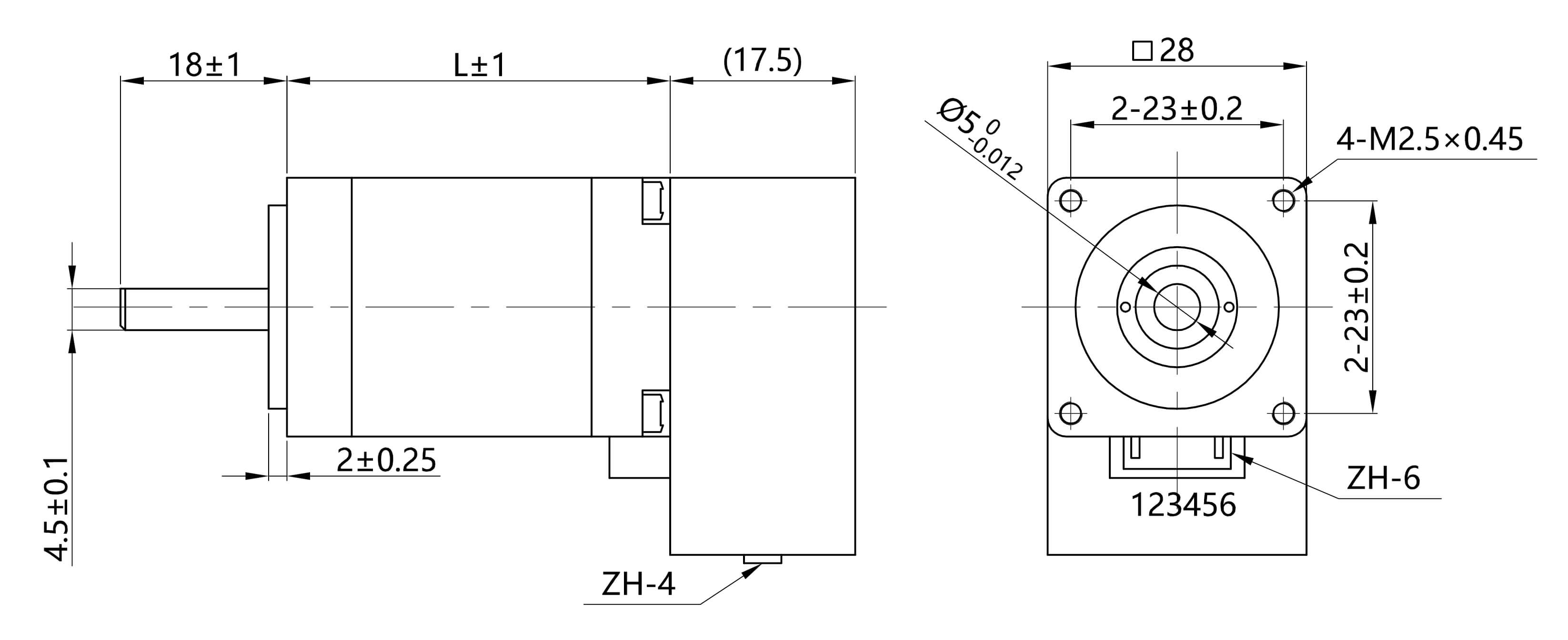

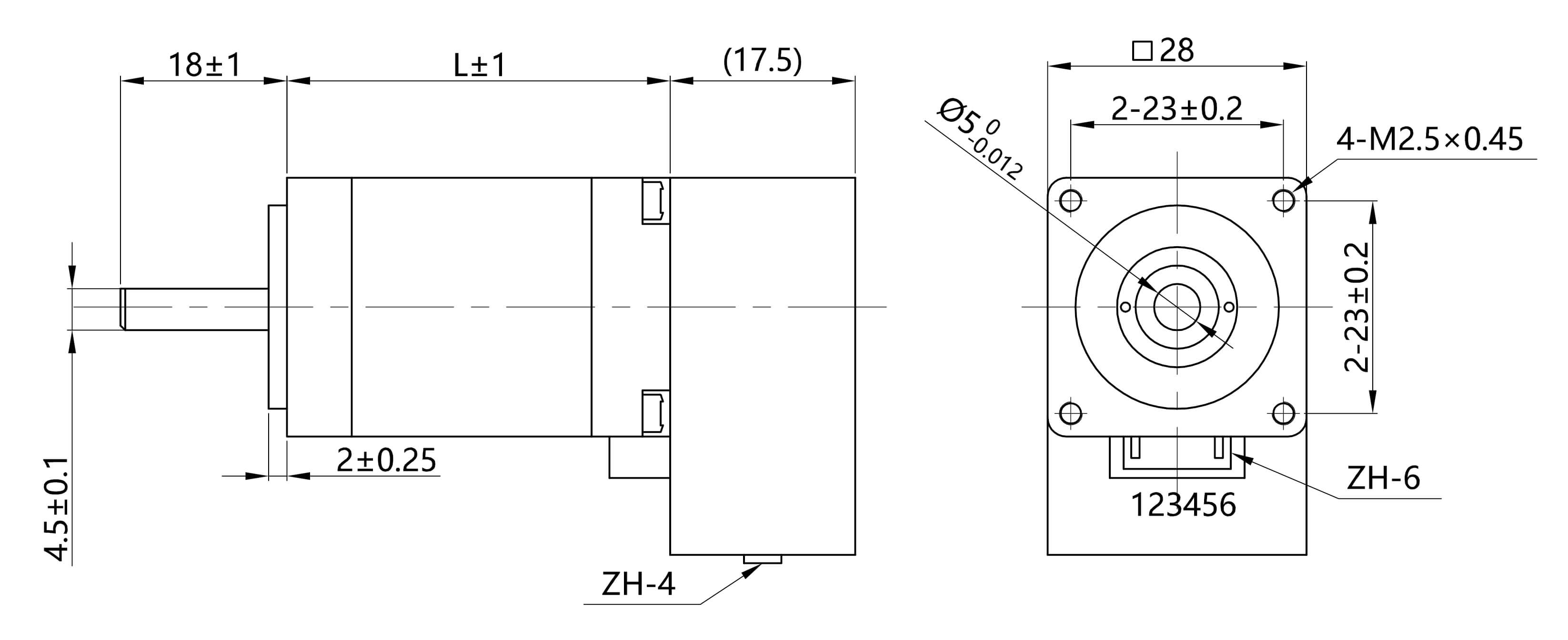

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm2 | Kg | |

| LM28HSN006 | 1.8 | 32 | 0.67 | 5.6 | 3.4 | 600 | 4 | 9 | 0.11 |

| LM28HSN009 | 1.8 | 45 | 0.67 | 6.8 | 4.9 | 950 | 4 | 12 | 0.14 |

| LM28HSN012 | 1.8 | 51 | 0.67 | 9.2 | 7.2 | 1200 | 4 | 18 | 0.2 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm2 | Kg | |

| LM28HSN006 | 1.8 | 32 | 0.67 | 5.6 | 3.4 | 600 | 4 | 9 | 0.11 |

| LM28HSN009 | 1.8 | 45 | 0.67 | 6.8 | 4.9 | 950 | 4 | 12 | 0.14 |

| LM28HSN012 | 1.8 | 51 | 0.67 | 9.2 | 7.2 | 1200 | 4 | 18 | 0.2 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

It is a compact NEMA 11 stepper motor integrated with an encoder and closed-loop control, combining the positioning accuracy of stepper motors with the reliability of servo-style feedback.

Closed-loop control continuously monitors rotor position through the encoder and corrects errors in real time, preventing step loss and improving motion reliability.

Closed-loop stepper motors offer higher efficiency, reduced heat generation, smoother motion, higher usable torque, and fault detection capabilities.

NEMA 11 closed-loop stepper motors typically use high-resolution magnetic or optical encoders to provide accurate position feedback.

The standard step angle is 1.8°, which can be further refined using microstepping and encoder feedback.

With encoder feedback and microstepping, the motor achieves high positioning accuracy and repeatability, even under dynamic loads.

Although compact, the motor delivers stable torque suitable for light-load precision applications such as small automation systems and medical devices.

Yes. The closed-loop system adjusts current dynamically, reducing unnecessary power consumption and lowering operating temperature.

The motor requires a dedicated closed-loop stepper driver that supports encoder feedback and real-time error correction.

Typical applications include robotics, semiconductor equipment, laboratory automation, medical instruments, pick-and-place systems, and compact CNC equipment.

Yes. Encoder resolution can be customized to meet different precision and control requirements.

Yes. Coil resistance and rated current can be customized to match specific power supplies and drivers.

Factories can provide customized shaft lengths, diameters, D-shafts, threaded ends, or special machining.

Yes. Planetary or spur gearboxes can be integrated to increase torque and improve load handling.

Yes. Cable type, length, connector model, and pin configuration can be tailored to customer systems.

Yes. Many factories offer complete closed-loop stepper motor and driver kits for easier integration.

OEM and ODM services are supported, including custom labels, laser marking, packaging, and documentation.

Yes. Motor design, encoder tuning, and driver parameter optimization can be adjusted to reduce noise and vibration.

MOQ depends on the customization level but is generally flexible for OEM and long-term customers.

Quality is ensured through incoming material inspection, encoder calibration, torque and speed testing, closed-loop accuracy verification, and final aging tests.

It is a compact NEMA 11 stepper motor integrated with an encoder and closed-loop control, combining the positioning accuracy of stepper motors with the reliability of servo-style feedback.

Closed-loop control continuously monitors rotor position through the encoder and corrects errors in real time, preventing step loss and improving motion reliability.

Closed-loop stepper motors offer higher efficiency, reduced heat generation, smoother motion, higher usable torque, and fault detection capabilities.

NEMA 11 closed-loop stepper motors typically use high-resolution magnetic or optical encoders to provide accurate position feedback.

The standard step angle is 1.8°, which can be further refined using microstepping and encoder feedback.

With encoder feedback and microstepping, the motor achieves high positioning accuracy and repeatability, even under dynamic loads.

Although compact, the motor delivers stable torque suitable for light-load precision applications such as small automation systems and medical devices.

Yes. The closed-loop system adjusts current dynamically, reducing unnecessary power consumption and lowering operating temperature.

The motor requires a dedicated closed-loop stepper driver that supports encoder feedback and real-time error correction.

Typical applications include robotics, semiconductor equipment, laboratory automation, medical instruments, pick-and-place systems, and compact CNC equipment.

Yes. Encoder resolution can be customized to meet different precision and control requirements.

Yes. Coil resistance and rated current can be customized to match specific power supplies and drivers.

Factories can provide customized shaft lengths, diameters, D-shafts, threaded ends, or special machining.

Yes. Planetary or spur gearboxes can be integrated to increase torque and improve load handling.

Yes. Cable type, length, connector model, and pin configuration can be tailored to customer systems.

Yes. Many factories offer complete closed-loop stepper motor and driver kits for easier integration.

OEM and ODM services are supported, including custom labels, laser marking, packaging, and documentation.

Yes. Motor design, encoder tuning, and driver parameter optimization can be adjusted to reduce noise and vibration.

MOQ depends on the customization level but is generally flexible for OEM and long-term customers.

Quality is ensured through incoming material inspection, encoder calibration, torque and speed testing, closed-loop accuracy verification, and final aging tests.