- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Motor Length: 32mm / 45mm /51mm

| Availability: | |

|---|---|

| Quantity: | |

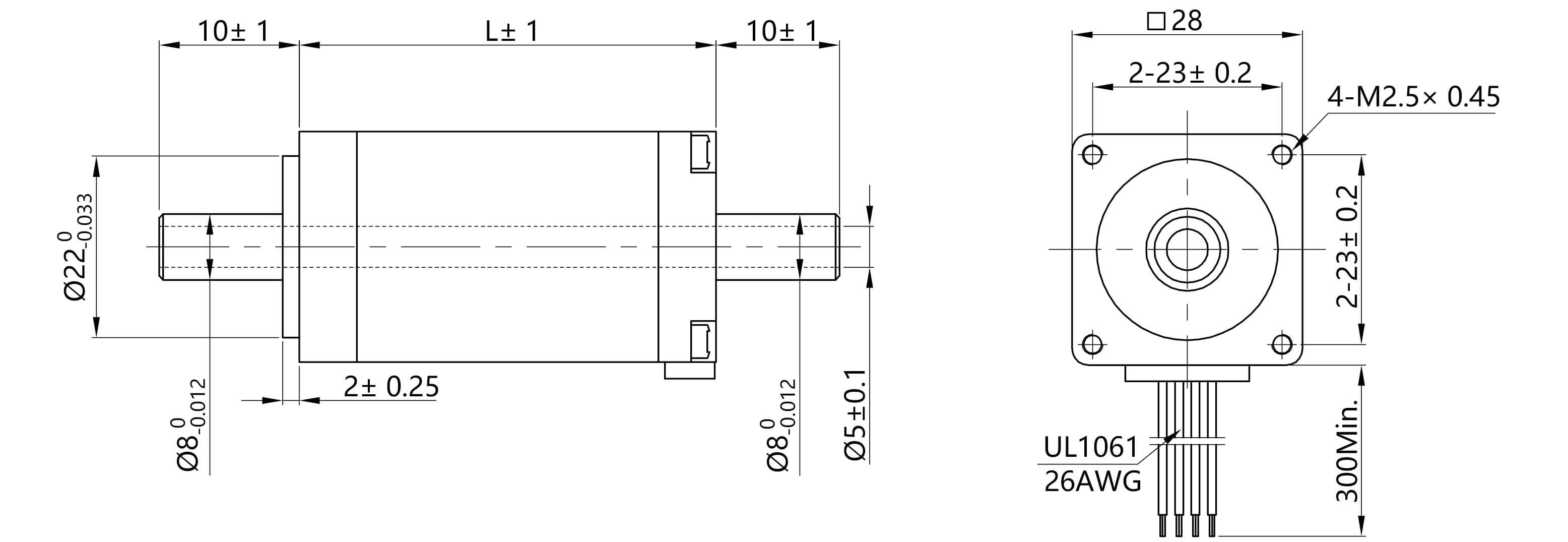

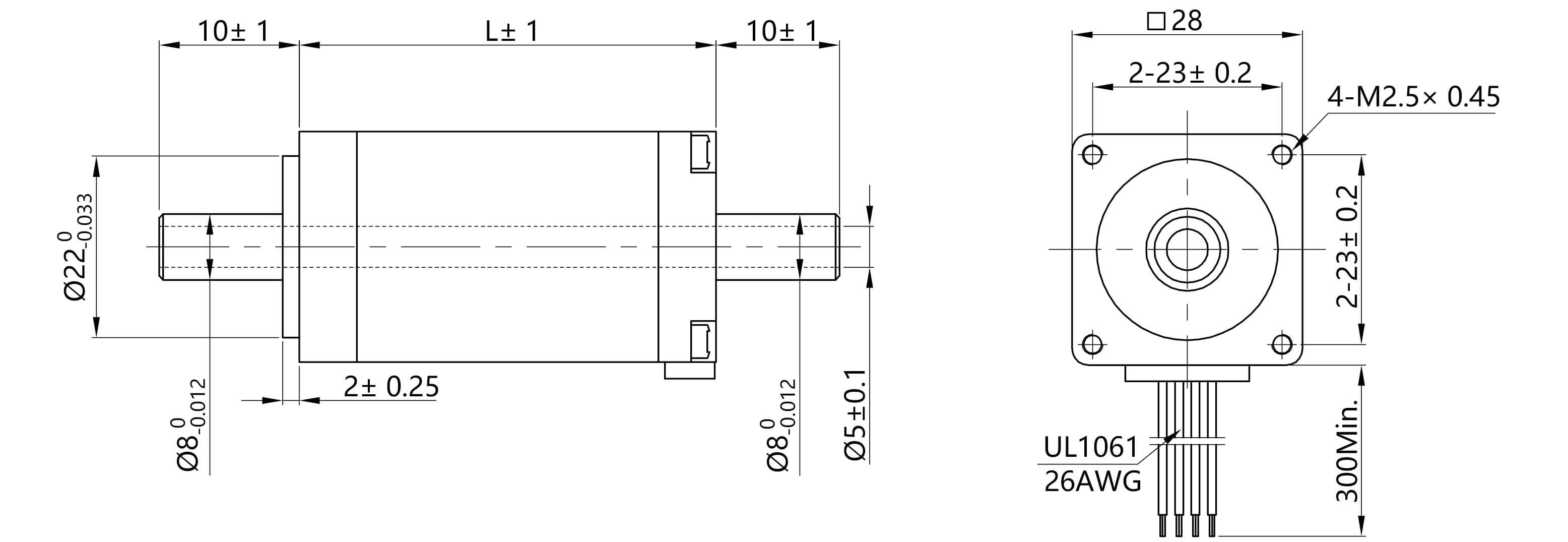

Nema 11 Hollow Shaft Stepper Motor

LEANMOTOR

Hollow Shaft Motors

Nema11 (28mm)

4wires

2 Phase

1.8°

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm² | kg | |

| LM28HSH32-0604 | 1.8 | 32 | 0.67 | 5.6 | 3.4 | 600 | 4 | 9 | 0.11 |

| LM28HSH45-0604 | 1.8 | 45 | 0.67 | 6.8 | 4.9 | 950 | 4 | 12 | 0.14 |

| LM28HSH51-0604 | 1.8 | 51 | 0.67 | 9.2 | 7.2 | 1200 | 4 | 18 | 0.2 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | g.cm | No. | g.cm² | kg | |

| LM28HSH32-0604 | 1.8 | 32 | 0.67 | 5.6 | 3.4 | 600 | 4 | 9 | 0.11 |

| LM28HSH45-0604 | 1.8 | 45 | 0.67 | 6.8 | 4.9 | 950 | 4 | 12 | 0.14 |

| LM28HSH51-0604 | 1.8 | 51 | 0.67 | 9.2 | 7.2 | 1200 | 4 | 18 | 0.2 |

| A+ | A- | B+ | B- |

| Black | Green | Red | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

(NEMA 11 Hollow Shaft Stepper Motor)

1. What is a NEMA 11 hollow shaft stepper motor used for?

A NEMA 11 hollow shaft stepper motor is commonly used in compact automation systems such as medical devices, laboratory instruments, 3D printers, optical equipment, and precision positioning applications.

2. What are the main advantages of a hollow shaft stepper motor?

The hollow shaft allows cables, optical fibers, fluid tubes, or lead screws to pass through the motor, enabling more compact and flexible mechanical designs.

3. What is the frame size of a NEMA 11 stepper motor?

NEMA 11 refers to a 1.1 × 1.1 inch (28 × 28 mm) mounting face, making it ideal for space-constrained applications.

4. What step angle does the NEMA 11 hollow shaft motor provide?

Most NEMA 11 stepper motors offer a standard 1.8° step angle (200 steps per revolution), ensuring precise positioning.

5. Is the NEMA 11 hollow shaft stepper motor suitable for high-precision motion control?

Yes, it provides accurate positioning and repeatability, especially when combined with microstepping drivers.

6. What type of winding does this stepper motor use?

It typically uses a hybrid stepper motor design, combining permanent magnet and variable reluctance technology for higher torque and accuracy.

7. What voltage and current ratings are supported?

The motor supports low-voltage operation with rated current optimized for small motion control systems and driver compatibility.

8. Can this motor operate continuously?

Yes, it is designed for continuous-duty operation within rated current and temperature limits.

9. What applications benefit most from a hollow shaft design?

Applications such as rotary tables, encoders, slip rings, robotic joints, and linear actuators benefit significantly from hollow shaft designs.

10. Is the NEMA 11 hollow shaft motor compatible with standard stepper drivers?

Yes, it works with most standard stepper motor drivers available on the market.

11. Can Lean Motor customize the hollow shaft diameter?

Yes, hollow shaft inner diameter and shaft length can be customized to meet specific mechanical design requirements.

12. Are custom winding options available for different torque or speed needs?

Lean Motor can customize winding parameters to optimize torque, speed, and current for specific applications.

13. Can the motor be customized for different lead wire lengths or connectors?

Yes, lead wire length, connector type, and pin configuration can be customized for easy installation.

14. Is customization available for holding torque or detent torque?

The factory can adjust magnetic design and winding structure to meet specific torque requirements.

15. Can the motor be paired with a customized stepper driver?

Lean Motor offers matched motor-driver solutions to ensure optimal performance and simplified integration.

16. Are special materials available for high-temperature or harsh environments?

Yes, insulation class, bearing type, and materials can be customized for demanding environments.

17. Does Lean Motor support OEM or private labeling services?

OEM branding, custom labeling, and packaging services are available for distributors and equipment manufacturers.

18. Can the motor be integrated with encoders or feedback devices?

The factory can integrate encoders or provide motor designs compatible with external feedback systems.

19. Is low-MOQ or prototype customization supported?

Yes, Lean Motor supports small-batch production and prototype development for testing and validation.

20. What technical support is available for customized NEMA 11 hollow shaft motors?

Lean Motor provides full technical support, including motor selection guidance, drawings, testing support, and after-sales service.

(NEMA 11 Hollow Shaft Stepper Motor)

1. What is a NEMA 11 hollow shaft stepper motor used for?

A NEMA 11 hollow shaft stepper motor is commonly used in compact automation systems such as medical devices, laboratory instruments, 3D printers, optical equipment, and precision positioning applications.

2. What are the main advantages of a hollow shaft stepper motor?

The hollow shaft allows cables, optical fibers, fluid tubes, or lead screws to pass through the motor, enabling more compact and flexible mechanical designs.

3. What is the frame size of a NEMA 11 stepper motor?

NEMA 11 refers to a 1.1 × 1.1 inch (28 × 28 mm) mounting face, making it ideal for space-constrained applications.

4. What step angle does the NEMA 11 hollow shaft motor provide?

Most NEMA 11 stepper motors offer a standard 1.8° step angle (200 steps per revolution), ensuring precise positioning.

5. Is the NEMA 11 hollow shaft stepper motor suitable for high-precision motion control?

Yes, it provides accurate positioning and repeatability, especially when combined with microstepping drivers.

6. What type of winding does this stepper motor use?

It typically uses a hybrid stepper motor design, combining permanent magnet and variable reluctance technology for higher torque and accuracy.

7. What voltage and current ratings are supported?

The motor supports low-voltage operation with rated current optimized for small motion control systems and driver compatibility.

8. Can this motor operate continuously?

Yes, it is designed for continuous-duty operation within rated current and temperature limits.

9. What applications benefit most from a hollow shaft design?

Applications such as rotary tables, encoders, slip rings, robotic joints, and linear actuators benefit significantly from hollow shaft designs.

10. Is the NEMA 11 hollow shaft motor compatible with standard stepper drivers?

Yes, it works with most standard stepper motor drivers available on the market.

11. Can Lean Motor customize the hollow shaft diameter?

Yes, hollow shaft inner diameter and shaft length can be customized to meet specific mechanical design requirements.

12. Are custom winding options available for different torque or speed needs?

Lean Motor can customize winding parameters to optimize torque, speed, and current for specific applications.

13. Can the motor be customized for different lead wire lengths or connectors?

Yes, lead wire length, connector type, and pin configuration can be customized for easy installation.

14. Is customization available for holding torque or detent torque?

The factory can adjust magnetic design and winding structure to meet specific torque requirements.

15. Can the motor be paired with a customized stepper driver?

Lean Motor offers matched motor-driver solutions to ensure optimal performance and simplified integration.

16. Are special materials available for high-temperature or harsh environments?

Yes, insulation class, bearing type, and materials can be customized for demanding environments.

17. Does Lean Motor support OEM or private labeling services?

OEM branding, custom labeling, and packaging services are available for distributors and equipment manufacturers.

18. Can the motor be integrated with encoders or feedback devices?

The factory can integrate encoders or provide motor designs compatible with external feedback systems.

19. Is low-MOQ or prototype customization supported?

Yes, Lean Motor supports small-batch production and prototype development for testing and validation.

20. What technical support is available for customized NEMA 11 hollow shaft motors?

Lean Motor provides full technical support, including motor selection guidance, drawings, testing support, and after-sales service.