- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

LMBLD2200

LeanMotor

10 Pcs

LMBLD2200 brushless DC motor driver is our company's latest high-tech product for the field of high power motor drive. This product uses a large-scale integrated circuit to replace the original hardware. It has higher anti-jamming and fast response ability. It is suitable for all the three-phase brushless DC motors with low voltage DC310V and current below 10A. Even if working with large current, it is still in low temperature.

● It has double speed closed current design with low speed torque and smooth operation;

● It has high speed output with the maximum speed of 10000rpm / min;

● Speed control mode : analog quantity 0-5V

● It has have EN, DIR signal control side;

● It can output tachometer pulse (optoelectronic isolation, gate output);

● It has over-current, overvoltage, under voltage , overheating, motor stalling and other protection functions

LMBLD2200 brushless DC motor driver is our company's latest high-tech product for the field of high power motor drive. This product uses a large-scale integrated circuit to replace the original hardware. It has higher anti-jamming and fast response ability. It is suitable for all the three-phase brushless DC motors with low voltage DC310V and current below 10A. Even if working with large current, it is still in low temperature.

● It has double speed closed current design with low speed torque and smooth operation;

● It has high speed output with the maximum speed of 10000rpm / min;

● Speed control mode : analog quantity 0-5V

● It has have EN, DIR signal control side;

● It can output tachometer pulse (optoelectronic isolation, gate output);

● It has over-current, overvoltage, under voltage , overheating, motor stalling and other protection functions

| Brand | Leanmotor |

| Model | LMBLD2200 |

| Driver Type | DC Brushless Motor Driver |

| DC / AC | DC/AC |

| Suitable Motor | 3-Phase DC Brushless motor |

| Input Voltage | AC100V - AC250V |

| Output Current | Max 10A |

| Motor speed range | 0rpm - 10000rpm |

| Power Supply | AC100V~250V direct current (Capacity according to motor power selection) |

The maximum input current | Not greater than 10 A (according to motor and rated load) |

The maximum power | The maximum is 2200W (over power motor is strictly prohibited) |

Insulation resistance | General temperature﹥500MΩ |

Insulation strength | General temperature and pressure 0.5KV,1minitute |

Cooling method | Natural air cooling& forced air cooling | |

Environment | Condition | Avoid dust, oil mist and corrosive gases |

Temperature | 0℃~+50℃ | |

Humidity | ﹤80% RH,no condensation, no frost | |

Vibration | 5.9m/s² max | |

Reserved temperature | -20℃~+65℃ | |

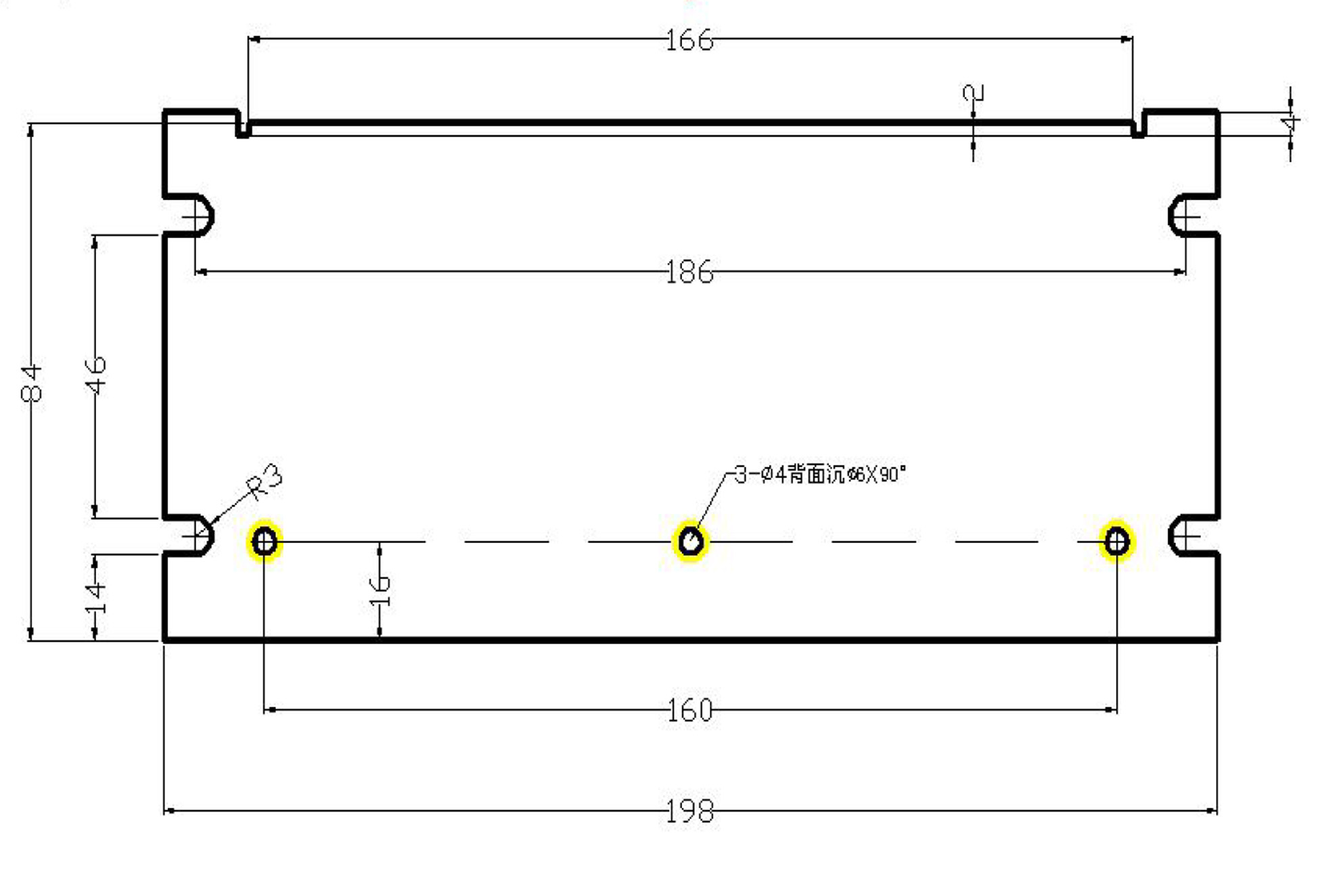

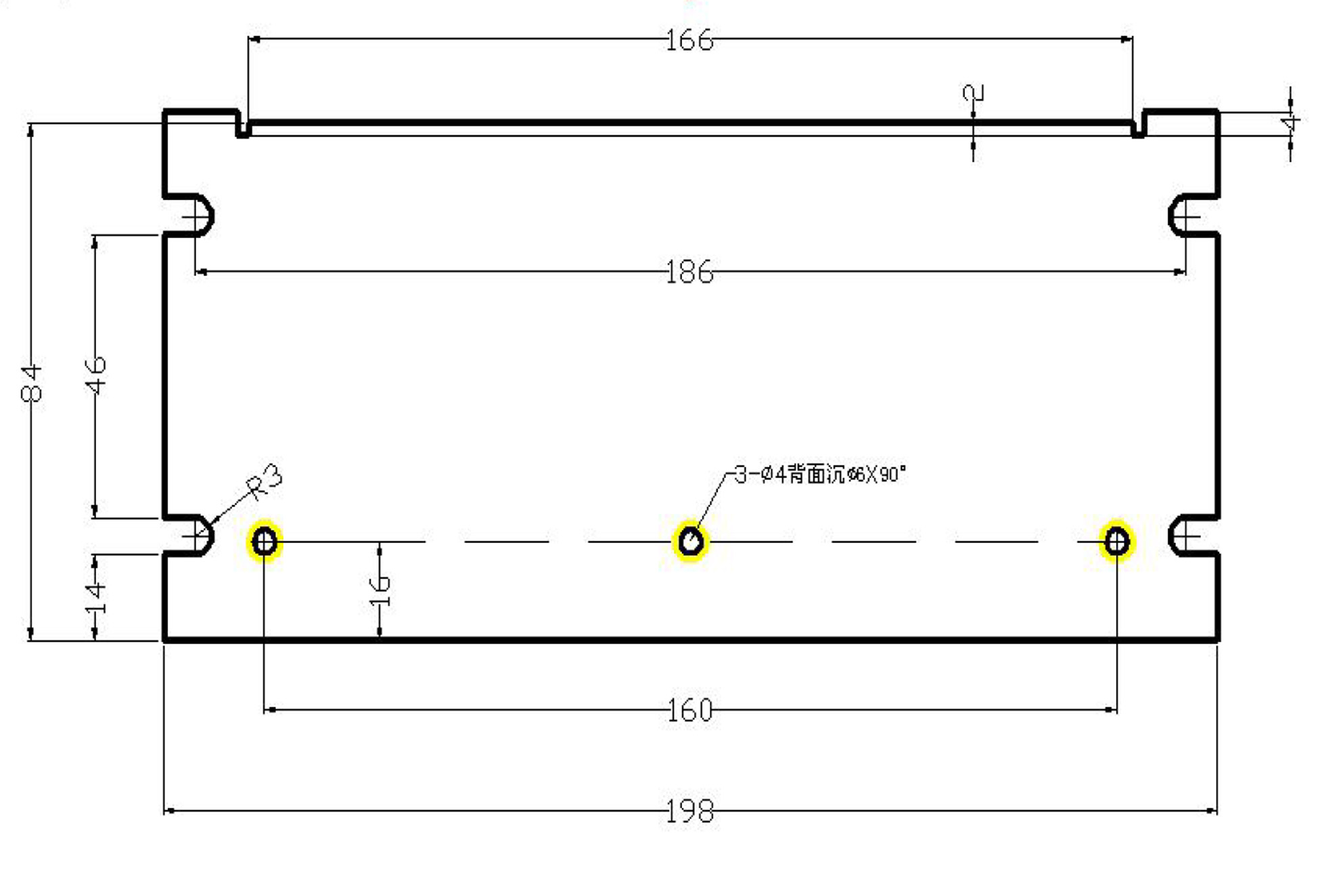

Size | 198mmX103mmX86mm | |

Weight | About 1Kg | |

Note: Due to dramatic changes in the temperature of the storage environment, it is easy to form condensation or frost. In this case, the drive should be placed for 12 hours or more. Until the drive temperature and ambient temperature is consistent, it can be on power.

Signal category | Terminal | Functional Description |

Indicator light | POWER | If the green power indicator is lighten, it shows that power is normal. |

ALM | If the red status indicator is slow flash, it means waiting; Quick flash means operation; It always lights meaning faults or off-line; | |

Control signal port | +5V1 | Control signal power+( inner power output ) |

VSP | External speed control signal Control way: By connecting with a potentiometer to change VSP, then it can complete 0 ~ 100% speed adjustment. The range is 0-5V | |

FG | Motor speed pulse output is measuring the frequency of this signal. Then converts it into the actual motor speed. | |

DIR | Rotary direction is controlled by high and low electrical level, motor forward: connected with GND1, motor reversal (anticlockwise) ;without GND1 or connected with +5V, motor forward (clockwise) | |

EN | Connected EN with GND1, motor can work(online status);without connected or high electrical lever, motor can not work(offline status and the red light keep working) | |

Hall control port | +5V2 | + motor’s Hall power |

HU | Hall sensor signal U phase input | |

HV | Hall sensor signal V phase input | |

HW | Hall sensor signal W phase input | |

GND2 | The motor’s Hall power supply | |

The motor and power | U、V、W | The motor’s three-phase output signal |

AC1、AC2 | The input power is AC100V~250V. |

Speed mode (VSP/PWM) | 1. The external input speed: two external terminals of the external potentiometer(5K-10K) respectively connected to the driver's GND1 and +5 V1 terminal. If the regulator is connected to the VSP end, you can use an external potentiometer to adjust speed. It can also be made by the other control unit’s (such as PLC, microcontroller, etc.) input analog voltage to VSP side (relative to GND1). VSP port accepts the range of DC 0V ~ +5 V and the corresponding motor speed is 0 ~ rated speed; |

Speed signal output (FG) | The drive provides the motor speed pulse signal, which is positive proportion to the motor speed, pulse output way: light lotus root isolation, 1. the motor speed (RPM) = F ÷ N× 60 F = actually measured frequency current on the FG foot by frequency table N = 2 or 4, 2-pole motor, N = 2; 4-pole motor, N = 4 For example: the user selects a 4-level motor. When the output FG signal is 200Hz, the motor speed = 200 ÷ 4× 60 = 3000 r / min. 2.optoelectronic isolation, gate output |

The motor positive and negative signal(DIR) | By controlling high low-level of DIR to control the motor’s positive and reverse turn. Noticed: Swerved suddenly when motor is at high speed, to avoid the damage of motor and equipment , when DIR get the transform single , we must make motor stop running for 1s, then change the motor direction ,improve speed to the set value. |

Start/Stop signal(EN) | By controlling high low-level of EN to control the motor’s stop and run. When EN is low level, motor run; when EN is high level or non-connect ,motor stop working, red light keep working. When control motor stop by EN port, it is nature stop, and the run regular is related with overloading inertia. Power Consumption is less than or equal to 20mA. Fault Value: short circuit with EN and GND1 |

| Brand | Leanmotor |

| Model | LMBLD2200 |

| Driver Type | DC Brushless Motor Driver |

| DC / AC | DC/AC |

| Suitable Motor | 3-Phase DC Brushless motor |

| Input Voltage | AC100V - AC250V |

| Output Current | Max 10A |

| Motor speed range | 0rpm - 10000rpm |

| Power Supply | AC100V~250V direct current (Capacity according to motor power selection) |

The maximum input current | Not greater than 10 A (according to motor and rated load) |

The maximum power | The maximum is 2200W (over power motor is strictly prohibited) |

Insulation resistance | General temperature﹥500MΩ |

Insulation strength | General temperature and pressure 0.5KV,1minitute |

Cooling method | Natural air cooling& forced air cooling | |

Environment | Condition | Avoid dust, oil mist and corrosive gases |

Temperature | 0℃~+50℃ | |

Humidity | ﹤80% RH,no condensation, no frost | |

Vibration | 5.9m/s² max | |

Reserved temperature | -20℃~+65℃ | |

Size | 198mmX103mmX86mm | |

Weight | About 1Kg | |

Note: Due to dramatic changes in the temperature of the storage environment, it is easy to form condensation or frost. In this case, the drive should be placed for 12 hours or more. Until the drive temperature and ambient temperature is consistent, it can be on power.

Signal category | Terminal | Functional Description |

Indicator light | POWER | If the green power indicator is lighten, it shows that power is normal. |

ALM | If the red status indicator is slow flash, it means waiting; Quick flash means operation; It always lights meaning faults or off-line; | |

Control signal port | +5V1 | Control signal power+( inner power output ) |

VSP | External speed control signal Control way: By connecting with a potentiometer to change VSP, then it can complete 0 ~ 100% speed adjustment. The range is 0-5V | |

FG | Motor speed pulse output is measuring the frequency of this signal. Then converts it into the actual motor speed. | |

DIR | Rotary direction is controlled by high and low electrical level, motor forward: connected with GND1, motor reversal (anticlockwise) ;without GND1 or connected with +5V, motor forward (clockwise) | |

EN | Connected EN with GND1, motor can work(online status);without connected or high electrical lever, motor can not work(offline status and the red light keep working) | |

Hall control port | +5V2 | + motor’s Hall power |

HU | Hall sensor signal U phase input | |

HV | Hall sensor signal V phase input | |

HW | Hall sensor signal W phase input | |

GND2 | The motor’s Hall power supply | |

The motor and power | U、V、W | The motor’s three-phase output signal |

AC1、AC2 | The input power is AC100V~250V. |

Speed mode (VSP/PWM) | 1. The external input speed: two external terminals of the external potentiometer(5K-10K) respectively connected to the driver's GND1 and +5 V1 terminal. If the regulator is connected to the VSP end, you can use an external potentiometer to adjust speed. It can also be made by the other control unit’s (such as PLC, microcontroller, etc.) input analog voltage to VSP side (relative to GND1). VSP port accepts the range of DC 0V ~ +5 V and the corresponding motor speed is 0 ~ rated speed; |

Speed signal output (FG) | The drive provides the motor speed pulse signal, which is positive proportion to the motor speed, pulse output way: light lotus root isolation, 1. the motor speed (RPM) = F ÷ N× 60 F = actually measured frequency current on the FG foot by frequency table N = 2 or 4, 2-pole motor, N = 2; 4-pole motor, N = 4 For example: the user selects a 4-level motor. When the output FG signal is 200Hz, the motor speed = 200 ÷ 4× 60 = 3000 r / min. 2.optoelectronic isolation, gate output |

The motor positive and negative signal(DIR) | By controlling high low-level of DIR to control the motor’s positive and reverse turn. Noticed: Swerved suddenly when motor is at high speed, to avoid the damage of motor and equipment , when DIR get the transform single , we must make motor stop running for 1s, then change the motor direction ,improve speed to the set value. |

Start/Stop signal(EN) | By controlling high low-level of EN to control the motor’s stop and run. When EN is low level, motor run; when EN is high level or non-connect ,motor stop working, red light keep working. When control motor stop by EN port, it is nature stop, and the run regular is related with overloading inertia. Power Consumption is less than or equal to 20mA. Fault Value: short circuit with EN and GND1 |

1. What is the LMBLD2200 brushless DC motor driver used for?

The LMBLD2200 is designed to control brushless DC motors in applications such as automation equipment, robotics, conveyors, AGVs, medical devices, and industrial motion control systems.

2. What voltage range does the LMBLD2200 BLDC driver support?

It supports a wide DC input voltage range, making it suitable for both low-voltage and medium-power BLDC motor applications.

3. What control modes are supported by the LMBLD2200 driver?

The driver supports multiple control modes, including speed control, torque control, and direction control, enabling flexible system integration.

4. Does the LMBLD2200 support Hall sensor feedback?

Yes, it is compatible with Hall sensor feedback, ensuring stable commutation and accurate motor control at low and high speeds.

5. Can the LMBLD2200 driver operate without Hall sensors?

The driver is primarily optimized for Hall-sensor-based BLDC motors, offering reliable startup and smooth operation.

6. What protection functions are built into the LMBLD2200?

It includes over-current, over-voltage, under-voltage, overheating, and short-circuit protection to enhance system safety and reliability.

7. Is the LMBLD2200 suitable for continuous industrial operation?

Yes, it is designed for long-term, continuous operation in industrial environments with stable thermal performance.

8. What communication or control signals does the driver accept?

The driver supports standard analog and digital control signals, making it easy to integrate with PLCs, controllers, and embedded systems.

9. How compact is the LMBLD2200 motor driver?

The compact design allows easy installation in space-limited control cabinets and integrated motor-drive systems.

10. What types of BLDC motors are compatible with the LMBLD2200?

It is compatible with a wide range of three-phase brushless DC motors used in industrial and commercial applications.

11. Can Lean Motor customize the LMBLD2200 for specific voltage or current requirements?

Yes, Lean Motor offers customization for voltage range, current rating, and power level to match specific motor and application needs.

12. Is it possible to customize control logic or parameters for OEM projects?

Factory customization includes firmware parameter tuning and control logic optimization for OEM and ODM applications.

13. Can the driver be customized for specific BLDC motor models?

Yes, the factory can match the driver precisely to your motor’s electrical characteristics, such as pole pairs and Hall sequence.

14. Does Lean Motor support private labeling or branding for the driver?

Private labeling, logo printing, and custom packaging are available for brand owners and distributors.

15. Can connector types and cable lengths be customized?

Yes, connectors, wiring harnesses, and cable lengths can be customized to simplify customer installation and reduce assembly time.

16. Is thermal design customization available for high-load applications?

Lean Motor can optimize heat dissipation solutions, including housing materials and thermal layouts, for high-duty applications.

17. Can protection thresholds be adjusted for special operating conditions?

Over-current, over-temperature, and voltage protection thresholds can be adjusted to meet specific environmental or load requirements.

18. Does the factory support small-batch or prototype customization?

Yes, Lean Motor supports low-MOQ customization and prototype development for testing and validation.

19. Can the driver be integrated into an integrated motor-drive solution?

The factory can provide integrated BLDC motor and driver solutions to reduce wiring, installation time, and system cost.

20. What technical support is available for customized LMBLD2200 drivers?

Lean Motor provides engineering support, technical documentation, parameter guidance, and after-sales support throughout the product lifecycle.

1. What is the LMBLD2200 brushless DC motor driver used for?

The LMBLD2200 is designed to control brushless DC motors in applications such as automation equipment, robotics, conveyors, AGVs, medical devices, and industrial motion control systems.

2. What voltage range does the LMBLD2200 BLDC driver support?

It supports a wide DC input voltage range, making it suitable for both low-voltage and medium-power BLDC motor applications.

3. What control modes are supported by the LMBLD2200 driver?

The driver supports multiple control modes, including speed control, torque control, and direction control, enabling flexible system integration.

4. Does the LMBLD2200 support Hall sensor feedback?

Yes, it is compatible with Hall sensor feedback, ensuring stable commutation and accurate motor control at low and high speeds.

5. Can the LMBLD2200 driver operate without Hall sensors?

The driver is primarily optimized for Hall-sensor-based BLDC motors, offering reliable startup and smooth operation.

6. What protection functions are built into the LMBLD2200?

It includes over-current, over-voltage, under-voltage, overheating, and short-circuit protection to enhance system safety and reliability.

7. Is the LMBLD2200 suitable for continuous industrial operation?

Yes, it is designed for long-term, continuous operation in industrial environments with stable thermal performance.

8. What communication or control signals does the driver accept?

The driver supports standard analog and digital control signals, making it easy to integrate with PLCs, controllers, and embedded systems.

9. How compact is the LMBLD2200 motor driver?

The compact design allows easy installation in space-limited control cabinets and integrated motor-drive systems.

10. What types of BLDC motors are compatible with the LMBLD2200?

It is compatible with a wide range of three-phase brushless DC motors used in industrial and commercial applications.

11. Can Lean Motor customize the LMBLD2200 for specific voltage or current requirements?

Yes, Lean Motor offers customization for voltage range, current rating, and power level to match specific motor and application needs.

12. Is it possible to customize control logic or parameters for OEM projects?

Factory customization includes firmware parameter tuning and control logic optimization for OEM and ODM applications.

13. Can the driver be customized for specific BLDC motor models?

Yes, the factory can match the driver precisely to your motor’s electrical characteristics, such as pole pairs and Hall sequence.

14. Does Lean Motor support private labeling or branding for the driver?

Private labeling, logo printing, and custom packaging are available for brand owners and distributors.

15. Can connector types and cable lengths be customized?

Yes, connectors, wiring harnesses, and cable lengths can be customized to simplify customer installation and reduce assembly time.

16. Is thermal design customization available for high-load applications?

Lean Motor can optimize heat dissipation solutions, including housing materials and thermal layouts, for high-duty applications.

17. Can protection thresholds be adjusted for special operating conditions?

Over-current, over-temperature, and voltage protection thresholds can be adjusted to meet specific environmental or load requirements.

18. Does the factory support small-batch or prototype customization?

Yes, Lean Motor supports low-MOQ customization and prototype development for testing and validation.

19. Can the driver be integrated into an integrated motor-drive solution?

The factory can provide integrated BLDC motor and driver solutions to reduce wiring, installation time, and system cost.

20. What technical support is available for customized LMBLD2200 drivers?

Lean Motor provides engineering support, technical documentation, parameter guidance, and after-sales support throughout the product lifecycle.