- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Motor Length: 38mm / 80mm

Rated voltage:24V / 48V

| Availability: | |

|---|---|

| Quantity: | |

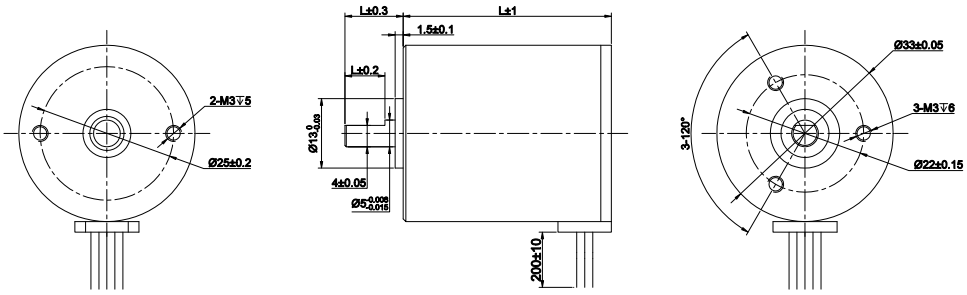

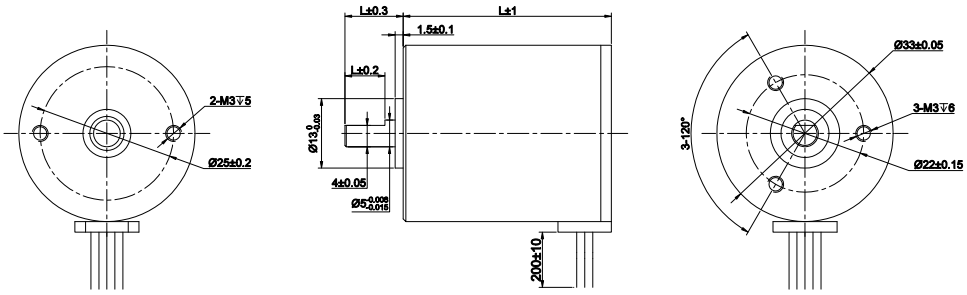

33BL Round Head Brushless BLDC DC Motor

LeanMotor

33mm

3 Phase

24V, 48V

10 Pcs

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Rated voltage | Motor Length | Current | Rated power | Inductance | Rated torque | Rated speed | Weight |

| VDC | (L)mm | A | W | mH | mN.m | Rpm | kg | |

| LM33BL30-24 | 24 | 30 | 1.5 | 7 | 7 | 22 | 3000 | 0.085 |

| LM33BL80-24 | 24 | 80 | 5.6 | 40 | 0.55 | 50 | 7800 | 0.2 |

| LM33BL80-48 | 48 | 80 | 2.9 | 40 | 1.45 | 40 | 10000 | 0.2 |

| Bldc Motors Wires | Hall Sensor Wires | ||||||

| U | V | W | +5VDC | GND | Hu | Hv | Hw |

| Yellow | Green | Blue | Red | Black | Yello | Green | Blue |

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

| Model No. | Rated voltage | Motor Length | Current | Rated power | Inductance | Rated torque | Rated speed | Weight |

| VDC | (L)mm | A | W | mH | mN.m | Rpm | kg | |

| LM33BL30-24 | 24 | 30 | 1.5 | 7 | 7 | 22 | 3000 | 0.085 |

| LM33BL80-24 | 24 | 80 | 5.6 | 40 | 0.55 | 50 | 7800 | 0.2 |

| LM33BL80-48 | 48 | 80 | 2.9 | 40 | 1.45 | 40 | 10000 | 0.2 |

| Bldc Motors Wires | Hall Sensor Wires | ||||||

| U | V | W | +5VDC | GND | Hu | Hv | Hw |

| Yellow | Green | Blue | Red | Black | Yello | Green | Blue |

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

Connectors, Gearbox, Encoder, Brake, Integrated Driver...

1. What is a 33BL round head brushless DC motor?

A 33BL round head brushless DC motor is a compact BLDC motor with a 33 mm diameter and round front flange, designed for smooth, efficient, and reliable operation.

2. What are the main advantages of a brushless DC motor compared to brushed motors?

Brushless DC motors offer higher efficiency, longer service life, lower noise, minimal maintenance, and better speed control.

3. What does “round head” mean in a BLDC motor?

The round head refers to the motor’s circular front mounting flange, which simplifies installation and improves mechanical alignment.

4. What voltage options are available for the 33BL brushless DC motor?

Typical voltage options include 12V and 24V, with other voltages available through customization.

5. What speed range can a 33BL brushless DC motor achieve?

The speed range depends on winding design and load conditions, making it suitable for both high-speed and controlled-speed applications.

6. Is the 33BL round head BLDC motor suitable for continuous operation?

Yes, brushless design allows stable continuous-duty operation with low heat generation.

7. What torque output can a 33BL brushless DC motor provide?

Torque output varies by motor length and winding configuration, suitable for light to medium load applications.

8. Can the 33BL BLDC motor operate with a gearbox?

Yes, it can be combined with planetary or spur gearboxes to increase output torque and reduce speed.

9. What industries commonly use 33BL round head brushless DC motors?

Common applications include medical devices, automation equipment, smart home products, pumps, fans, and small robotic systems.

10. How is speed controlled in a 33BL brushless DC motor?

Speed is typically controlled using a dedicated BLDC motor driver via PWM or analog input signals.

11. Can the 33BL round head brushless DC motor be customized?

Yes, manufacturers can customize voltage, speed, torque, motor length, and winding parameters.

12. Are different shaft types available for 33BL BLDC motors?

Yes, options include round shafts, D-shafts, keyed shafts, and custom shaft designs.

13. Can encoders or sensors be added to the motor?

Yes, Hall sensors or encoders can be integrated for speed and position feedback.

14. Can the factory provide matched BLDC motor drivers?

Yes, manufacturers often supply compatible BLDC motor drivers for optimal performance.

15. Are gearbox-integrated versions available?

Yes, the 33BL brushless DC motor can be combined with planetary or spur gearboxes.

16. Can the motor be designed for low-noise or low-vibration applications?

Yes, optimized electromagnetic design and precision bearings reduce noise and vibration.

17. Are waterproof or dustproof versions available?

Customized IP-rated designs (such as IP54 or IP65) can be provided for special environments.

18. What quality control tests are performed on 33BL brushless DC motors?

Testing includes speed and torque testing, efficiency testing, noise testing, thermal testing torque testing, efficiency testing, noise testing, thermal testing, and endurance testing.

19. What is the typical lead time for custom 33BL brushless DC motors?

Prototype samples usually take 2–4 weeks, while mass production typically requires 4–8 weeks.

20. How does factory-level customization improve system performance?

Customization ensures the motor is precisely matched to application requirements, improving efficiency, reliability, and service life.

1. What is a 33BL round head brushless DC motor?

A 33BL round head brushless DC motor is a compact BLDC motor with a 33 mm diameter and round front flange, designed for smooth, efficient, and reliable operation.

2. What are the main advantages of a brushless DC motor compared to brushed motors?

Brushless DC motors offer higher efficiency, longer service life, lower noise, minimal maintenance, and better speed control.

3. What does “round head” mean in a BLDC motor?

The round head refers to the motor’s circular front mounting flange, which simplifies installation and improves mechanical alignment.

4. What voltage options are available for the 33BL brushless DC motor?

Typical voltage options include 12V and 24V, with other voltages available through customization.

5. What speed range can a 33BL brushless DC motor achieve?

The speed range depends on winding design and load conditions, making it suitable for both high-speed and controlled-speed applications.

6. Is the 33BL round head BLDC motor suitable for continuous operation?

Yes, brushless design allows stable continuous-duty operation with low heat generation.

7. What torque output can a 33BL brushless DC motor provide?

Torque output varies by motor length and winding configuration, suitable for light to medium load applications.

8. Can the 33BL BLDC motor operate with a gearbox?

Yes, it can be combined with planetary or spur gearboxes to increase output torque and reduce speed.

9. What industries commonly use 33BL round head brushless DC motors?

Common applications include medical devices, automation equipment, smart home products, pumps, fans, and small robotic systems.

10. How is speed controlled in a 33BL brushless DC motor?

Speed is typically controlled using a dedicated BLDC motor driver via PWM or analog input signals.

11. Can the 33BL round head brushless DC motor be customized?

Yes, manufacturers can customize voltage, speed, torque, motor length, and winding parameters.

12. Are different shaft types available for 33BL BLDC motors?

Yes, options include round shafts, D-shafts, keyed shafts, and custom shaft designs.

13. Can encoders or sensors be added to the motor?

Yes, Hall sensors or encoders can be integrated for speed and position feedback.

14. Can the factory provide matched BLDC motor drivers?

Yes, manufacturers often supply compatible BLDC motor drivers for optimal performance.

15. Are gearbox-integrated versions available?

Yes, the 33BL brushless DC motor can be combined with planetary or spur gearboxes.

16. Can the motor be designed for low-noise or low-vibration applications?

Yes, optimized electromagnetic design and precision bearings reduce noise and vibration.

17. Are waterproof or dustproof versions available?

Customized IP-rated designs (such as IP54 or IP65) can be provided for special environments.

18. What quality control tests are performed on 33BL brushless DC motors?

Testing includes speed and torque testing, efficiency testing, noise testing, thermal testing torque testing, efficiency testing, noise testing, thermal testing, and endurance testing.

19. What is the typical lead time for custom 33BL brushless DC motors?

Prototype samples usually take 2–4 weeks, while mass production typically requires 4–8 weeks.

20. How does factory-level customization improve system performance?

Customization ensures the motor is precisely matched to application requirements, improving efficiency, reliability, and service life.